Why Is a Profile Straightening Machine Essential for Precision?

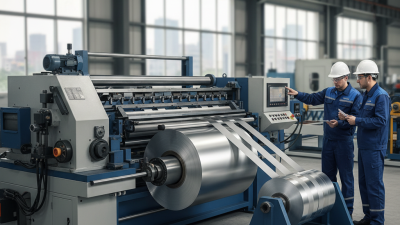

In many manufacturing processes, precision is key. A profile straightening machine plays a crucial role in achieving that precision. These machines are designed to correct the shape and alignment of metal profiles. As components pass through, they receive pressure to straighten any bends or warps.

Imagine the frustration of using a misaligned part in assembly. Issues arise such as increased wear and malfunction. Such problems can lead to costly delays and defects. Thus, a profile straightening machine is not just a luxury—it's a necessity.

Manufacturers must consider the investment in this machinery. The initial costs may be high, but the long-term benefits are significant. Precision impacts overall quality and customer satisfaction. An effective profile straightening machine ensures that every product meets specific standards. While no machine is perfect, the right choice can minimize errors. Remember, even small deviations can lead to substantial issues over time.

Understanding the Functionality of Profile Straightening Machines

Profile straightening machines play a crucial role in various industries. They ensure the correct geometry of metal bars, tubes, and profiles. According to a recent industry report, about 25% of production defects stem from misalignment. This emphasizes the importance of straightening in manufacturing processes.

These machines operate by applying force to correct distortions. They help maintain tight tolerances. The precision they offer can be the difference between a successful product and a flawed one. For instance, a small deviation in measurements can lead to significant issues. This could result in costly rework or scrap.

**Tips:** When selecting a straightening machine, consider its capacity and design flexibility. Adjusting settings accurately is key. Regular maintenance also enhances performance. A poorly maintained machine may compromise accuracy. Therefore, it’s vital to establish a routine check-up schedule.

Profile straightening machines must adapt to different materials. Steel, aluminum, and polymers each require unique handling. Manufacturers should continually educate staff on best practices. An engaged team can spot inconsistencies early. Sometimes equipment doesn't perform as expected. Analyzing and reflecting on such events helps improve processes.

Why Is a Profile Straightening Machine Essential for Precision?

| Feature | Description | Importance | Applications |

|---|---|---|---|

| Material Versatility | Works with various materials including metals, plastics, and composites. | Allows for flexibility in manufacturing processes. | Automotive, aerospace, construction. |

| Precision Control | Advanced technology for accurate adjustments to straighten profiles. | Ensures high-quality output and reduces waste. | Fabrication of precise components. |

| User-Friendly Interface | Easy-to-use controls for operators. | Reduces training time and enhances productivity. | General manufacturing operations. |

| Automation Capability | Can be integrated into automated production lines. | Increases efficiency and lowers labor costs. | High-volume production. |

| Maintenance Requirements | Regular maintenance needed to ensure optimal performance. | Prolongs the lifespan of the machine. | All manufacturing settings. |

Key Benefits of Precision in Profile Straightening

Precision plays a crucial role in profile straightening. It allows for better alignment of materials, which is essential in many industries. When components are straightened accurately, they fit together seamlessly. This reduces the risk of defects in the final product. Inaccurate profiling can lead to costly errors and waste. Such mistakes often require time-consuming corrections.

Employing a profile straightening machine can significantly enhance precision. These machines ensure that every piece is processed uniformly. This uniformity allows for improved quality control. Workers can rely on consistent results rather than hoping for the best. Even minor discrepancies can lead to significant issues. Companies often find themselves re-evaluating their methods after experiencing setbacks.

However, achieving precision is not always straightforward. It requires careful calibration and skilled operators. Trained personnel must handle the equipment to avoid inaccuracies. The learning curve can be steep. Misalignment can still occur if users are not attentive. Reflecting on past mistakes helps in refining the process. Continuous improvements are necessary to maintain high standards.

Importance of Precision in Profile Straightening

The bar chart above illustrates the key benefits of precision in profile straightening. It highlights the importance of cost savings, quality enhancement, time efficiency, and customer satisfaction, showcasing how precision contributes to overall manufacturing excellence.

Common Applications of Profile Straightening Machines

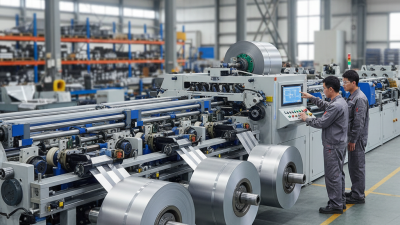

Profile straightening machines play a crucial role in various industries. They are designed to ensure that materials meet specific tolerances. This precision is vital for applications in construction, manufacturing, and automotive sectors.

In construction, straightened profiles are essential for building structures. Uneven materials can lead to structural weaknesses. In manufacturing, accurate profiles contribute to the efficiency of assembly lines. A slight bend can cause delays and increase costs. In the automotive industry, precision in metal profiles is non-negotiable. Any imperfection can compromise vehicle safety.

Despite their importance, some users overlook maintenance. This can lead to machine inefficiencies. Users sometimes underestimate the impact of a misaligned profile. Regular checks can prevent costly errors. Reflection on processes can improve overall output quality. Investing in routine care is essential for optimal operation.

Factors Influencing the Precision of Profile Straightening

Profile straightening machines play a crucial role in achieving precision in metal fabrication. Several key factors influence the accuracy of these machines. One significant aspect is the material properties being processed. For example, high-strength steel exhibits different deformation characteristics compared to softer metals. According to industry reports, variations in tensile strength can lead to discrepancies in straightening outcomes, affecting overall quality.

The machine's design and technology are also pivotal. Advanced straightening machines utilize precise rollers and algorithms to adjust force application. Precision up to 0.01mm can be achieved with the right setup. However, inconsistency in the calibration process remains a concern. Regular maintenance and updates on the software are essential for optimal performance. Neglecting these can lead to uneven profiles.

Environmental conditions, such as temperature and humidity, further complicate matters. These factors can alter material behavior, leading to unexpected results. A report by the Metal Industries Association cites that 15% of production issues stem from these environmental variables. Identifying and addressing these influences can help improve the effectiveness of profile straightening operations.

Maintenance Practices for Optimal Performance of Straightening Machines

Maintaining a profile straightening machine is crucial for achieving optimal performance. Regular upkeep helps prevent wear and tear. It also ensures that the machine operates at peak efficiency, leading to precise straightening results.

One key maintenance practice involves regular inspections. Check for signs of misalignment or wear on the rollers. Adjustments may be necessary even if everything seems fine. Small issues can escalate quickly if ignored. Look for any unusual noises during operation. These may indicate potential problems that require immediate attention.

Another important tip is cleaning components regularly. Dust and debris can accumulate and affect performance. Use a soft, lint-free cloth to wipe down surfaces. Keep lubricant levels appropriate to ensure smooth operation. If the machine isn’t lubricated enough, it might lead to overheating. This is something that could frustrate users and should be addressed.

Routine calibration is also essential. Ensure settings match material specifications. Over time, variations can occur that impact straightening. A simple recalibration can yield significant improvements. Don't overlook these aspects. Addressing them can prevent costly downtimes. Regular maintenance will save time and improve productivity.

Related Posts

-

How to Choose the Right Metal Cut to Length Machine for Your Business?

-

How to Choose the Best Automatic Length Cutting Machine for Your Needs?

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

How to Choose the Right Sheet Slitting Machine for Your Business?

-

Top 10 Benefits of Using a Metal Cut to Length Machine for Your Business?

-

What is a Sheet Metal Slitting Machine and How Does It Work?