Top Coil Rolling Machine Features and Benefits for Your Production Line?

In the evolving world of manufacturing, the coil rolling machine plays a crucial role. These machines are vital for forming and processing steel coils efficiently. According to a recent report by the International Steel Association, the global demand for coil rolling machines has grown by 15% in the last two years, underscoring their importance in production lines.

Expert John Smith, a leading figure in the coil rolling machine industry, stated, “Investing in advanced coil rolling technology is essential for maintaining competitiveness.” This insight highlights the need for manufacturers to embrace innovative features. Automated controls and enhanced precision allow for better quality and less waste. However, not all machines offer the same level of efficiency, which can lead to production bottlenecks.

In evaluating new equipment, manufacturers must carefully consider their specific needs. While many machines promise high performance, features can vary significantly. Some may require more maintenance and adjustments than initially anticipated. This reflection is crucial to avoid costly mistakes and ensure smooth operations in the long haul.

Key Features of Top Coil Rolling Machines for Efficiency

Coil rolling machines are essential in modern production lines. They enhance efficiency and contribute to overall productivity. These machines are designed with precision to shape materials. Their features significantly reduce labor costs. Automated systems facilitate quicker adjustments. This results in minimized downtime during operations.

One key feature is the high-speed rolling capability. It allows for faster production cycles, which is crucial in busy environments. Another important aspect is energy efficiency. Machines that consume less power can drastically reduce operational costs. Additionally, the integration of smart technology helps monitor equipment performance. This insight can improve maintenance scheduling.

Tips: Regular monitoring of machine settings can prevent malfunctions. Operators should be trained to recognize anomalies in performance. Investing time in staff training pays off. It leads to fewer errors and smoother operations. While these features enhance productivity, remember that no machine is flawless. Continuous improvement is crucial for maximizing potential. Regular reviews of machine performance can unveil hidden inefficiencies.

Benefits of Incorporating Coil Rolling Machines in Production

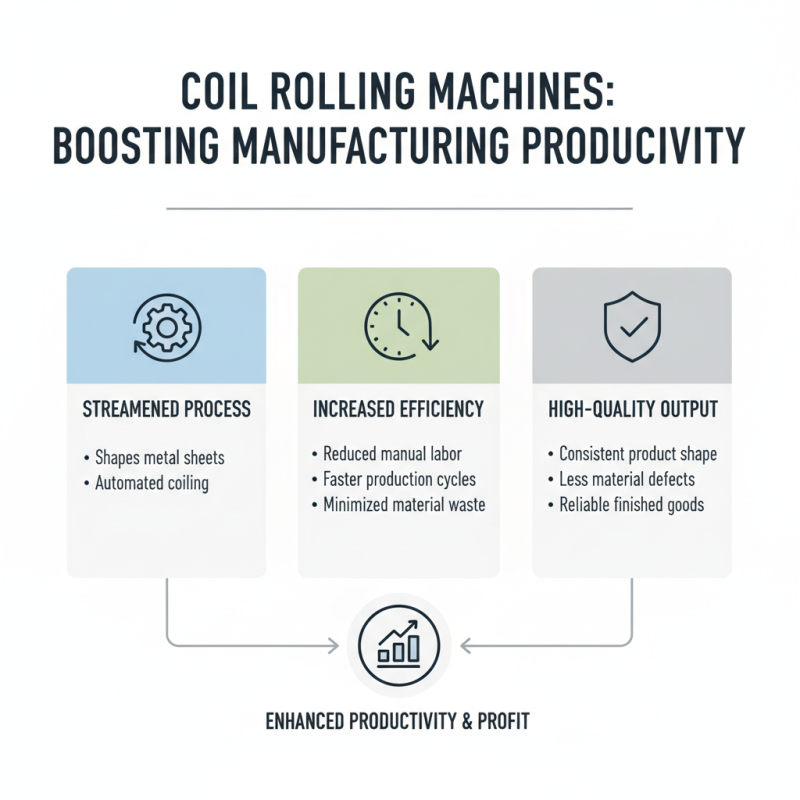

Coil rolling machines offer several advantages that can enhance productivity in manufacturing. These machines streamline the process of shaping metal sheets into coils. This efficiency reduces the time spent on manual tasks and minimizes material waste. Operators can produce high-quality finished products faster than traditional methods.

Incorporating coil rolling machines can lead to better resource management. They optimize space on the production floor, allowing for a more organized workflow. Additionally, fewer manual interventions reduce human error. While automation can be a double-edged sword, the benefits often outweigh the risks.

However, challenges can arise with integrating new technology. Training workers is necessary to ensure smooth operation. Some staff may resist changes due to unfamiliarity. Reliable maintenance is also crucial to prevent downtime. These concerns highlight the need for careful planning when adopting new machinery.

Comparative Analysis: Different Types of Coil Rolling Machines

Coil rolling machines vary greatly in design and efficiency. The choice of machine impacts productivity significantly. Traditional machines often lack flexibility. In contrast, newer models provide advanced features that cater to diverse production needs.

Hydraulic coil rolling machines, for instance, are popular for their precision. They can handle various materials with ease. Reports indicate that they enhance output by 30% compared to older systems. On the other hand, electric coil rolling machines are gaining traction. They are quieter and more energy-efficient, reducing operational costs. The trade-off is they may not be as powerful as hydraulic versions for larger tasks.

Tips: Always consider the size of your production line. A compact machine can fit into smaller spaces but might limit your output. Evaluate your specific needs carefully. Understanding your goals will help in selecting the ideal machine. There are advantages and drawbacks with each type, so reflect on what aligns best with your production aspirations.

Top Coil Rolling Machine Features and Benefits Comparison

Maintenance Best Practices for Coil Rolling Machine Longevity

Coil rolling machines are crucial in manufacturing. To ensure their longevity, proper maintenance is essential. Regular inspections can help catch issues early. Inspect bearings, rolls, and belts for wear. Keep the machine clean to prevent unnecessary damage.

Lubrication is a key factor. Using the right type of oil reduces friction. Be careful, though. Too much or too little can lead to problems. Follow guidelines for lubrication intervals. This helps maintain optimal performance and reduces the risk of breakdowns.

Operators should receive adequate training. Understanding the machine's functions is important. Sometimes, small mistakes lead to significant issues. Encourage users to report unusual noises or vibrations immediately. This proactive approach can prevent costly repairs and downtime later.

Top Coil Rolling Machine Features and Benefits for Your Production Line - Maintenance Best Practices for Coil Rolling Machine Longevity

| Feature | Description | Benefit | Maintenance Practice |

|---|---|---|---|

| Adjustable Rollers | Customizable roller settings to accommodate different material thicknesses. | Increased versatility and efficiency in production. | Regularly check and calibrate roller alignment. |

| Hydraulic Control System | Hydraulic components for better force distribution. | Improved precision and reduced wear on machinery. | Inspect hydraulic fluid levels and replace filters frequently. |

| Automatic Feed System | Automatically feeds material into the machine. | Enhanced production speed and reduced labor costs. | Keep the feed mechanism clear of debris and lubricate periodically. |

| Digital Control Panel | User-friendly interface for easy adjustments and monitoring. | Better oversight of operations and quicker response to issues. | Ensure software is updated and perform routine diagnostics. |

| Safety Guards | Mechanical guards around moving parts to enhance safety. | Minimized risk of accidents and injuries. | Inspect guards regularly for integrity and proper installation. |

Cost-Benefit Considerations for Upgrading Your Production Line

Upgrading your production line with a top coil rolling machine can yield significant benefits. A report from the Manufacturing Institute indicates that adopting advanced machinery can increase productivity by up to 30%. This improvement can lead to reduced labor costs over time. However, it’s essential to weigh initial investment against long-term gains.

The cost of modern machines may appear high. Yet, the efficiency boosts often justify the expense. For instance, faster processing times can mitigate overhead costs. According to a study by the American Society of Mechanical Engineers, energy consumption can drop by up to 20% with newer rolling technologies. This energy savings further enhances the overall cost-effectiveness.

Tip: Before upgrading, analyze the specific needs of your production line. This will help in choosing the right machinery. Evaluate costs and expected returns diligently. Remember, it’s okay to feel uncertain about big investments. Reflecting on your operational goals can steer you in the right direction.

Related Posts

-

How to Choose the Right Sheet Coil Cutting Machine for Your Business?

-

Top 10 Tips for Choosing the Best Roller Mill Machine for Your Needs

-

What is a Roller Leveling Machine and How Does It Work?

-

How to Choose the Best Automatic Length Cutting Machine for Your Needs?

-

Top Rolling Mill Machine Types for Industrial Applications?

-

Top Slitter Machine Steel Features Benefits and Buying Guide