The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

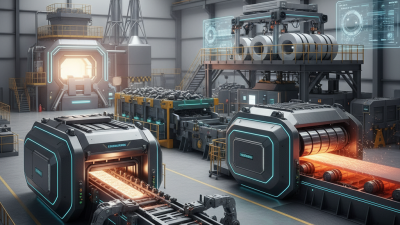

In the dynamic world of metal processing, the choice of machinery can significantly influence operational efficiency and product quality. One critical piece of equipment in this sector is the aluminum slitter machine, designed to offer precision cutting for aluminum coils. As noted by industry expert John Smith, “The right aluminum slitter machine not only enhances productivity but also ensures that the quality of the end products meets the highest standards.” This statement underscores the importance of selecting the appropriate slitter machine based on specific needs and production requirements.

When navigating the myriad of options available for aluminum slitter machines, it is essential to consider several factors including the machine's capacity, the thickness and width of the aluminum being processed, and the expected production speed. Additionally, understanding the technological features and customization options can aid in making an informed decision that aligns with your operational goals. This guide aims to provide comprehensive insight into the criteria for choosing the right aluminum slitter machine, ensuring that businesses can maximize their investment while maintaining quality and efficiency in their manufacturing processes.

Understanding Aluminum Slitter Machines: Key Features and Types

Aluminum slitter machines are essential equipment in the manufacturing sector, allowing for efficient processing of aluminum sheets into narrower strips. Understanding the key features of these machines is crucial for selecting the right model that meets your specific production requirements. One of the primary features to consider is the cutting mechanism, which can range from rotary shear to razor blade types. Each mechanism offers distinct advantages in terms of efficiency, precision, and maintenance needs. Moreover, a machine's capability to accommodate different thicknesses and widths of aluminum is vital for versatility in production.

In addition to the cutting mechanism, the type of slitter machine can greatly influence the output quality and operational speed. Two main types of aluminum slitters are primarily used: stationary and portable models. Stationary slitters are ideal for high-volume operations, providing stability and precision, while portable models offer flexibility and ease of use for smaller jobs. Another important aspect is the machine’s automation level, which can significantly enhance productivity and reduce labor costs. Understanding these key features and types will help you make informed decisions when selecting an aluminum slitter machine tailored to your unique needs.

Factors to Consider When Selecting an Aluminum Slitter Machine

When selecting an aluminum slitter machine, the first factor to consider is the machine's capacity and speed. It's essential to determine the volume of material you will be processing, as different machines are designed to handle various production rates. Consider the thickness and width of the aluminum sheets you typically work with, as this will influence both the type of slitter and its specifications.

Tips: Always assess the machine's adaptability to future production needs. A versatile slitter that can accommodate different materials and adjust to changing thicknesses can save you significant costs down the road.

Another critical factor is the level of automation and technology incorporated into the machine. Modern aluminum slitters can offer features such as automated threading, tension control, and real-time monitoring systems, which enhance efficiency and reduce labor costs. Evaluating how much automation you require based on your workforce and production goals can help narrow down your options.

Tips: If you have the opportunity, visit a facility with the machine you are considering. Observing its operation can provide valuable insights into its performance and ease of use.

Lastly, maintenance and support should not be overlooked. Consider how easy it is to access parts and the availability of technical support from the manufacturer. A reliable machine is often backed by a robust service network, ensuring minimal downtime and optimal performance.

Comparison of Slitting Methods: Shear vs. Rotary Slitters

When choosing an aluminum slitter machine, understanding the differences between shear and rotary slitting methods is crucial. Shear slitting utilizes sharp blades to cut the material, producing clean edges and tight tolerances. This method is often preferred for thicker aluminum sheets and applications requiring high precision. According to a recent market analysis, shear slitters can achieve an accuracy of up to ±0.002 inches, which is essential for industries demanding stringent quality standards.

On the other hand, rotary slitting employs rotating circular blades, allowing for higher speeds and greater productivity. This method is typically more efficient for thinner materials, capable of slitting at speeds exceeding 600 feet per minute in some configurations. Industry reports indicate that rotary slitting can enhance production rates by up to 30% compared to shear methods, making it a suitable choice for manufacturers focusing on volume rather than intricate detail. Each slitting method has distinct advantages and limitations; thus, aligning the choice with specific production needs ensures optimal performance and cost-effectiveness in aluminum processing.

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

| Slitting Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Shear Slitters | High precision cut, less burr | Higher maintenance, slower speed | Thicker materials |

| Rotary Slitters | Faster production speed, less waste | May cause more burr, less precision | Thin materials |

| Combination Slitters | Versatile, handles variety of materials | Complex setup, potentially higher cost | Mixed material requirements |

Industry Standards and Performance Metrics for Slitter Machines

When choosing the right aluminum slitter machine, understanding industry standards and performance metrics is crucial. Key performance indicators (KPIs) such as cutting accuracy, production speed, and maintenance requirements play significant roles in determining the overall efficiency of a slitter machine. Cutting accuracy is essential to ensure that the finished products meet dimensional specifications, with minimal waste. Industry standards often stipulate tolerances that machines must adhere to, directly impacting the machine’s reliability in high-volume production environments.

Additionally, production speed is a critical metric that affects a facility's throughput. The ability to process large quantities of aluminum in a given time frame can significantly enhance operational efficiency. Performance metrics such as maximum cutting speed and cycle time should be taken into account, as they will influence the productivity of the entire production line.

Moreover, it is important to consider the machine's ease of maintenance, as machines that require frequent repairs or downtime can disrupt workflow and increase operational costs. By prioritizing these industry standards and performance metrics, manufacturers can choose an aluminum slitter machine that best meets their specific needs and enhances their production capabilities.

Maintenance Tips for Optimal Performance of Aluminum Slitter Machines

Regular maintenance is crucial for ensuring the optimal performance of aluminum slitter machines. One of the key aspects is to frequently inspect and clean the cutting blades. Dull or contaminated blades can significantly affect the accuracy and quality of the cuts, leading to increased waste and downtime. It is advisable to develop a routine schedule for blade inspection and sharpening, which can help maintain cutting precision and prolong the lifespan of the machine.

In addition to blade maintenance, lubrication plays a vital role in the machine's overall functioning. Ensure that all moving parts are adequately lubricated to reduce friction and wear, which can prevent breakdowns. Utilize high-quality lubricants that are compatible with the machine components, and follow the manufacturer's recommendations on lubrication intervals. Keeping a detailed maintenance log can also help track service dates and performance issues, allowing for proactive adjustments to reduce the risk of costly repairs in the future.

Related Posts

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Top 10 HR Slitting Machines for Precision and Efficiency in 2023

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

What is a Roller Leveling Machine and How Does It Work?