Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

In the rapidly evolving industrial landscape of 2023, the demand for efficient processing and cutting of steel coils has reached unprecedented levels. The steel industry reports indicate that global steel demand is projected to grow by approximately 2.5% annually, driven by infrastructure expansion and manufacturing developments (World Steel Association, 2023). As steel plays a crucial role in various sectors, including construction and automotive, the importance of utilizing advanced machinery that can optimize operations is paramount.

A steel coil cutting machine represents an essential investment for manufacturers seeking to enhance their production capabilities. By employing cutting-edge technology, these machines not only improve cutting precision but also minimize waste, thereby maximizing profitability. According to a market analysis by Research and Markets (2023), the steel coil processing machinery market is expected to witness significant growth, with an anticipated CAGR (Compound Annual Growth Rate) of 6.7% over the next five years. This underscores the trend towards automation and efficiency in steel processing, and highlights the criticality of selecting the right cutting machinery to meet growing industrial demands.

As we explore the top seven steel coil cutting machines available this year, it is essential to consider their specifications and features that set them apart in an increasingly competitive market. These machines are designed to cater to various production needs while ensuring the highest standards of quality and efficiency, making them integral to any modern steel processing operation.

Top Features to Look for in Steel Coil Cutting Machines

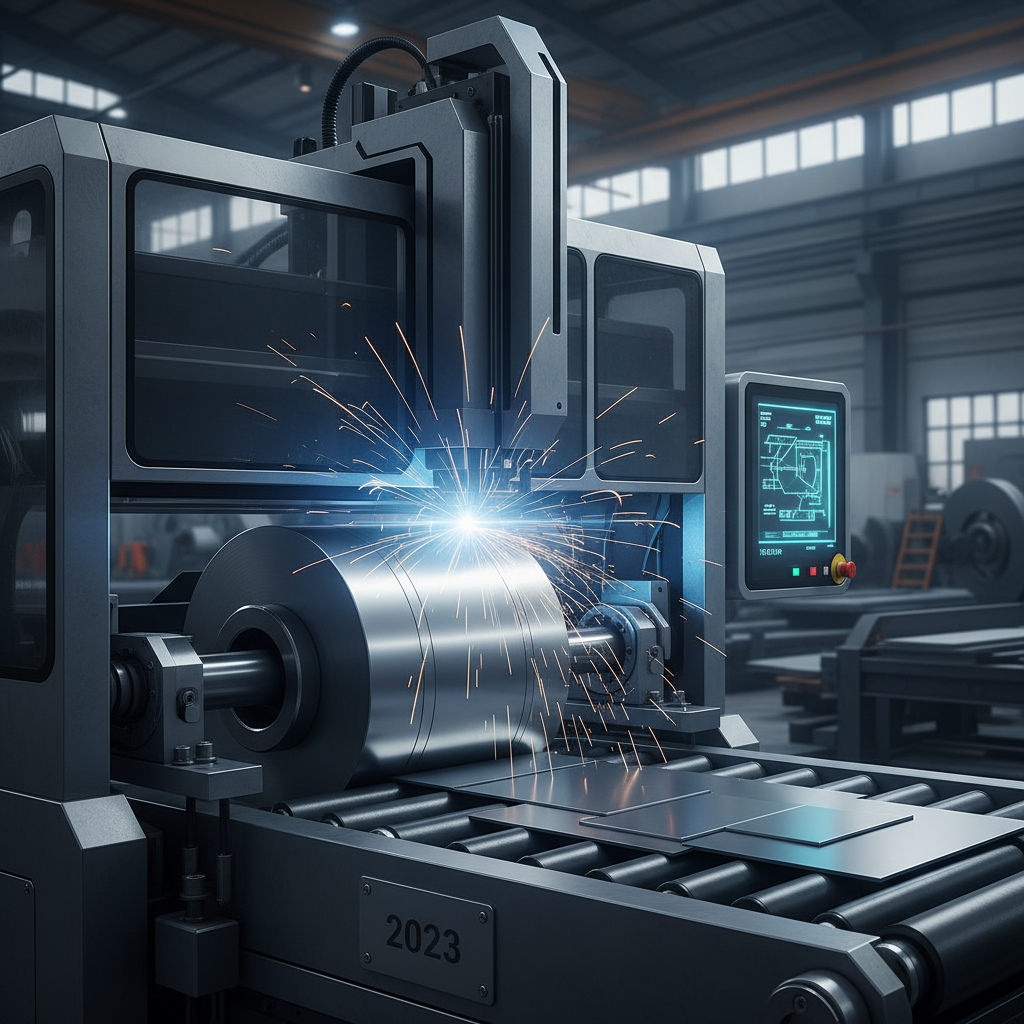

When selecting a steel coil cutting machine in 2023, certain features are essential to ensure optimal efficiency. One of the most critical attributes is precision cutting technology. Machines equipped with advanced laser or plasma cutting systems offer superior accuracy, enabling manufacturers to reduce waste and enhance the quality of the final product. Additionally, these technologies can accommodate various thicknesses and materials, making them versatile for different applications.

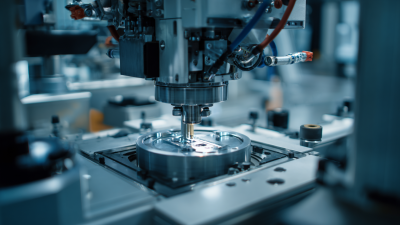

Another vital feature to consider is the machine's automation capabilities. Machines that incorporate CNC (Computer Numerical Control) and programmable settings allow for faster and more consistent production runs. This not only minimizes human error but also enables complex cutting patterns to be executed seamlessly. Furthermore, ease of operation and maintenance play a significant role in maximizing uptime and productivity, so selecting machines with user-friendly interfaces and quick maintenance access is advantageous for any manufacturing setup.

Comparative Analysis of Leading Steel Coil Cutting Machines in 2023

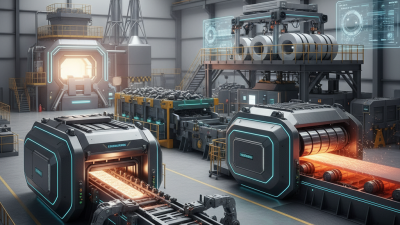

In 2023, the demand for efficient steel coil cutting machines has surged, prompting significant advancements in this sector. A comparative analysis of the leading machines reveals critical variations in performance metrics such as cutting speed, precision, and operational efficiency. Machines equipped with advanced CNC (Computer Numerical Control) technology stand out for their ability to deliver consistent results, minimizing waste and enhancing productivity in large-scale manufacturing processes.

Another key factor influencing the choice of cutting machines is their adaptability to different coil types and thicknesses. Some of the top models offer versatility, allowing operators to switch between cutting techniques effortlessly, from shearing to laser cutting. This flexibility not only saves time but also reduces downtime associated with machine changeovers. Overall, the innovations in steel coil cutting technology in 2023 reflect a growing emphasis on efficiency, quality, and user-friendly operation, setting new standards in the manufacturing industry.

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

| Machine Model | Cutting Speed (m/s) | Max Material Thickness (mm) | Operating Power (kW) | Weight (kg) | Efficiency Rating (%) |

|---|---|---|---|---|---|

| Model A | 10 | 12 | 50 | 1500 | 95 |

| Model B | 15 | 10 | 55 | 1200 | 90 |

| Model C | 8 | 15 | 45 | 1400 | 85 |

| Model D | 12 | 13 | 60 | 1600 | 92 |

| Model E | 18 | 8 | 70 | 1100 | 88 |

| Model F | 14 | 11 | 65 | 1500 | 93 |

| Model G | 16 | 9 | 75 | 1000 | 89 |

User Reviews: Insights on the Best Steel Coil Cutting Machines

When it comes to selecting the best steel coil cutting machines for optimal efficiency, user reviews play a crucial role in guiding potential buyers. Many operators emphasize the importance of precision and speed in these machines, with several highlighting models that boast advanced automation features. Users have indicated that machines equipped with programmable settings significantly reduce downtime and enhance productivity, making them ideal for high-demand environments.

Additionally, feedback from industry professionals reveals that durability and maintenance are key factors influencing their choices. Users who have invested in robust, quality machines report lower maintenance costs and longer operational lifespans. Several reviews also praise machines that offer versatile cutting capabilities, allowing users to handle various steel grades and thicknesses without compromising performance. This adaptability proves essential for manufacturers aiming to optimize their production processes while maintaining high-quality output.

Cost-Efficiency: Evaluating the ROI of Top Steel Coil Cutting Machines

When evaluating the return on investment (ROI) of top steel coil cutting machines, it becomes crucial to consider not only their initial costs but also long-term operational efficiency. Given the winding machines market's projected growth, expected to reach $8840M by 2035, investing in high-quality cutting machines can yield significant returns through improved productivity and reduced waste. By choosing machines that optimize cutting precision and speed, manufacturers can enhance their output without incurring substantial additional costs.

Tips: When selecting steel coil cutting machines, prioritize those with energy-efficient features to lower operating expenses. Additionally, consider machinery with advanced technology that can adapt to various coil sizes and thicknesses, as versatility often leads to better cost efficiency in the long run.

As the industry trends towards greater automation and digital integration, investing in machines that facilitate these advancements can be particularly beneficial. By evaluating technology and potential cost savings meticulously, businesses can ensure that their investments in cutting machines contribute positively to their overall financial success.

Future Trends in Steel Coil Cutting Technology: What to Expect

Advancements in steel coil cutting technology are poised to shape the future of the industry substantially. The global slitting machine market, crucial for efficient steel coil processing, is expected to reach approximately USD 525.9 million by 2024, growing at a steady rate of 3.0% annually. This growth underscores the increasing need for advanced cutting solutions that enhance productivity and minimize waste in steel production environments. As the demand for steel products continues to rise, especially with the projected robust increase in India's steel production, the innovation in cutting technology will play a pivotal role in meeting these needs efficiently.

Moreover, the pre-painted steel coil market is set for remarkable growth, projected to expand from USD 12.1 billion in 2024 to USD 24.3 billion by 2035, representing a compound annual growth rate (CAGR) of 6.6%. Such trends highlight the significant shifts in consumer preferences towards high-quality, durable steel products, driving manufacturers to invest in cutting-edge technologies. As the industry adapts to these dynamics, companies are likely to develop more sophisticated machines that not only provide precision cutting but also integrate smarter technologies for improved operational efficiency and sustainability in steel manufacturing.

Related Posts

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions