Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs

When it comes to workshop efficiency, having the right tools at your disposal can make all the difference. One crucial piece of equipment that every fabricator or metalworker should consider is the pipe straightener machine. This innovative device is designed to eliminate bends and curves from piping, ensuring that materials are perfectly straightened for a variety of applications. As the demand for precision in metalworking continues to grow, understanding the capabilities of pipe straightener machines becomes increasingly important for anyone looking to optimize their workflow.

In the market today, there are a multitude of options when it comes to pipe straightener machines. With varying designs, functionalities, and specifications, choosing the right one can be a daunting task. This guide will explore the top five pipe straightener machines available, highlighting their key features and benefits to help workshop owners make informed decisions. Whether you're working with thin-walled tubing or heavier pipes, a quality pipe straightener machine can enhance both the quality and efficiency of your projects, making it an invaluable addition to your workshop arsenal.

Top 5 Pipe Straightener Machines: Key Features and Specifications

When selecting a pipe straightener machine for your workshop, understanding the key features and specifications that enhance efficiency and performance is crucial. A recent industry report indicates that the demand for high-performance pipe processing equipment has surged by over 15% annually, driven by the growth in construction and manufacturing sectors. A reliable pipe straightener typically offers features such as

adjustable bending radius, heavy-duty construction, and an efficient alignment mechanism to handle various pipe sizes and materials effectively.

Another important specification to consider is the machine's throughput capacity. Many pipe straighteners can process up to 120 pipes per hour, with a minimum bend radius as tight as 1.5 times the pipe diameter. Advanced options include digital displays for real-time monitoring of the straighten process, ensuring precision and reducing material waste.

Moreover, user-friendly interfaces and safety features such as emergency stop buttons and protective covers have become standard in modern designs, providing operators with both convenience and security while working in demanding environments.

As the market evolves, staying informed about these key features will help you make an informed decision when investing in a pipe straightener that meets your workshop's specific needs.

Factors to Consider When Choosing a Pipe Straightener Machine

When selecting a pipe straightener machine, several key factors should be carefully evaluated to ensure you’re making the best investment for your workshop. First, consider the material types and pipe sizes that your projects typically require. According to industry reports, machines that offer versatility in accommodating various diameters and materials tend to be more efficient in high-demand settings. Choosing a machine that can handle a range of pipe materials—such as stainless steel, aluminum, and carbon steel—enhances its utility across different applications.

Next, look into the machine’s performance specifications, particularly its straightening capacity and speed. Data from mechanical engineering journals indicates that high-performance machines can achieve straightening accuracies of up to 0.5 mm per meter of pipe length, significantly reducing rework and material wastage. Additionally, the speed of the straightening process can impact overall productivity; therefore, machines with faster throughput capabilities are preferred in environments where time efficiency is critical. Lastly, ease of use and maintenance should not be overlooked, as machines that are user-friendly and require minimal downtime for maintenance can substantially improve operational efficiency in a workshop setting.

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs

| Model | Pipe Diameter Range | Max Straightening Force | Weight | Price Range |

|---|---|---|---|---|

| Model A | 1/2" to 2" | 5 tons | 150 lbs | $1,200 - $1,500 |

| Model B | 3/4" to 3" | 6 tons | 180 lbs | $1,800 - $2,200 |

| Model C | 1" to 4" | 8 tons | 200 lbs | $2,500 - $3,000 |

| Model D | 1/2" to 5" | 10 tons | 220 lbs | $3,000 - $3,500 |

| Model E | 1" to 6" | 12 tons | 250 lbs | $3,800 - $4,500 |

Comparison of Efficiency and Performance Metrics in Pipe Straightening

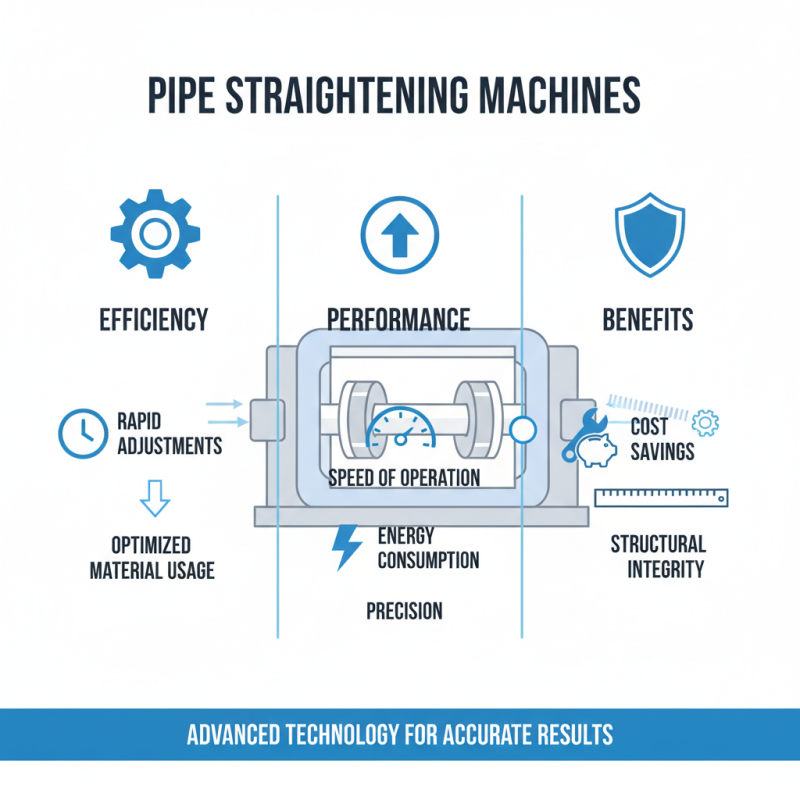

When it comes to pipe straightening, selecting the right machine can significantly impact both efficiency and performance. The best machines incorporate advanced technologies that allow for rapid adjustments and accurate results, ensuring that the pipes are straightened without compromising their structural integrity. Performance metrics such as the speed of operation, energy consumption, and the precision of the straightening process are crucial in determining the effectiveness of these machines in a workshop environment. Efficient machines not only save time but also optimize material usage, which can lead to cost savings in the long run.

Moreover, the versatility of pipe straighteners greatly affects their performance. Machines that can accommodate a range of pipe sizes and materials often deliver better results and meet diverse workshop needs. The ability to produce consistently straight pipes while maintaining high throughput is essential, especially in high-demand production scenarios. Workshops looking to enhance their operations should prioritize machines that offer automated features for monitoring and quality assurance, ensuring that each pipe meets stringent performance standards. By focusing on these efficiency and performance metrics, workshops can make informed decisions about their investment in pipe straightening technology.

Safety Standards and Compliance for Pipe Straightening Equipment

When it comes to pipe straightening equipment, adhering to safety standards and compliance guidelines is of paramount importance. According to the Occupational Safety and Health Administration (OSHA), ensuring that all equipment used in the workshop meets safety regulations can significantly reduce workplace accidents. In fact, businesses compliant with safety standards report up to a 40% decrease in workplace injuries, as indicated in a recent industry report by the National Safety Council (NSC). Proper training for operators, along with regular equipment inspections, aligns with these safety standards to foster a secure working environment.

Moreover, the American National Standards Institute (ANSI) sets forth guidelines concerning the design and operation of pipe straightening machines. Compliance with ANSI standards not only enhances operational efficiency but also provides protection against possible legal liabilities. A study conducted by the Industrial Equipment Association (IEA) found that manufacturers adhering to these compliance measures experience 30% fewer equipment failures, translating into lower maintenance costs and promoting longer machine life. Therefore, selecting pipe straightening machines that meet these rigorous safety and compliance standards is not just a financial decision; it's a commitment to worker safety and operational excellence in any workshop setting.

Top 5 Pipe Straightener Machines: Performance Comparison

Industry Trends Impacting the Future of Pipe Straightener Machines

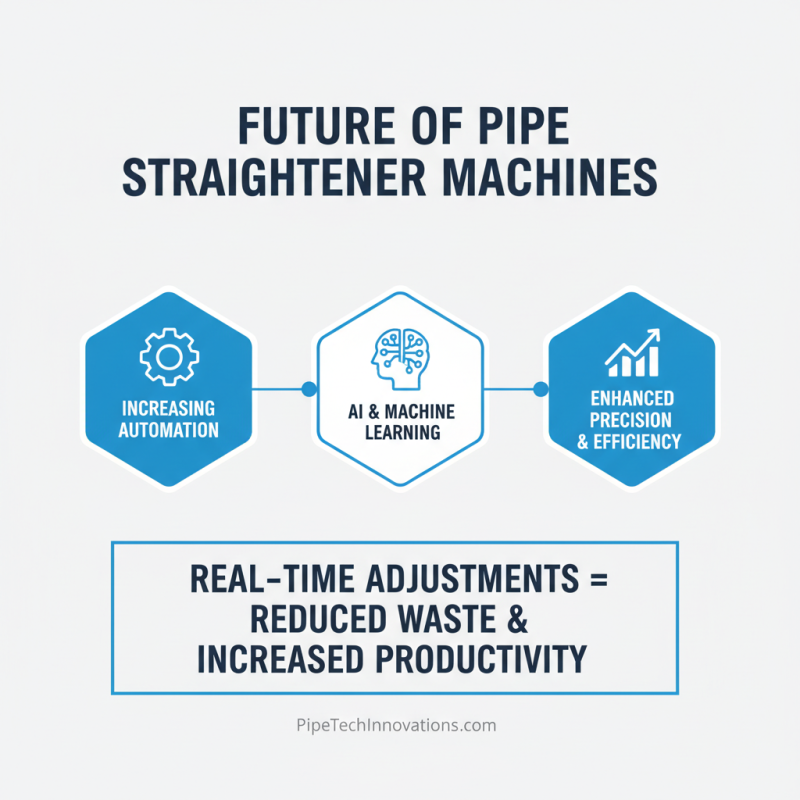

The future of pipe straightener machines is being shaped by several key industry trends that reflect advancements in technology and changing market demands. One significant trend is the increasing automation of industrial processes. Manufacturers are investing in smart machinery equipped with artificial intelligence and machine learning capabilities to enhance precision and efficiency. These advancements allow for real-time adjustments during the straightening process, significantly reducing waste and increasing productivity.

Another trend shaping the industry is the growing emphasis on sustainability. As environmental concerns escalate, pipe straightener machines are being designed to minimize energy consumption and waste generation. Innovations in material engineering are leading to more durable and environmentally friendly components, which not only extend the lifespan of the machines but also reduce the overall environmental footprint of manufacturing operations. This focus on sustainability is crucial for companies aiming to meet regulatory requirements and consumer expectations for eco-friendly practices.

Lastly, the customization of pipe straightener machines is becoming increasingly vital. With the diverse needs of various industries, manufacturers are developing machines that can be tailored to specific requirements, allowing for greater flexibility and efficiency. This shift towards personalization in industrial equipment underlines the importance of understanding customer needs and adapting to the rapidly changing landscape of manufacturing processes. As these trends continue to unfold, the industry is poised for significant transformation, ensuring that pipe straightener machines remain an essential tool in modern workshops.

Related Posts

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry