Top 10 HR Slitting Machines for Precision and Efficiency in 2023

In today's fast-paced manufacturing environment, precision and efficiency are paramount, especially in the realm of material processing. The HR slitting machine has emerged as a critical component to meet these demands, offering manufacturers the ability to achieve high-quality cuts with minimal waste. According to a recent industry report by Research and Markets, the global slitting machines market is projected to grow significantly in the coming years, driven by the increasing demand for precision-engineered products across various sectors such as automotive, electronics, and packaging.

As we delve into the top 10 HR slitting machines for 2023, it is essential to consider not only the technological advancements that enhance performance but also the operational efficiencies that these machines can deliver. The adoption of smart technology and automation features has led to substantial improvements in production rates and quality assurance, with some manufacturers reporting efficiency gains up to 30%. With the growing emphasis on sustainability and cost-effectiveness, the right HR slitting machine can empower businesses to optimize their processes while maintaining the standards required in today’s competitive market. As we explore the top contenders in this category, it becomes clear that investing in state-of-the-art HR slitting machines is not just a business decision; it's a strategic move towards future-proofing operations in an ever-evolving landscape.

Overview of HR Slitting Machines and Their Applications

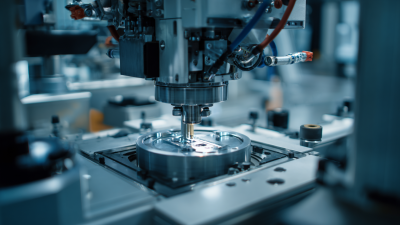

HR slitting machines are essential tools in the manufacturing industry, designed for precise cutting of materials such as metals, plastics, and composites. These machines operate by feeding the material through rotating blades, enabling accurate slitting into specific widths. The versatility of HR slitting machines makes them invaluable in various applications, including the production of packaging materials, automotive components, and electronic devices. Their ability to handle different thicknesses and materials without compromising on quality ensures that manufacturers can meet diverse production needs.

In recent years, advancements in technology have enhanced the efficiency and precision of HR slitting machines. Features such as automated controls and enhanced blade design reduce setup times and improve cutting accuracy. These improvements not only optimize production processes but also minimize waste, making HR slitting machines more environmentally friendly. As industries continue to demand higher quality and faster production rates, the role of HR slitting machines will remain pivotal in driving innovation and efficiency in manufacturing operations.

Criteria for Selecting Top HR Slitting Machines in 2023

When selecting the top HR slitting machines in 2023, it is essential to consider several critical criteria to ensure precision and efficiency. First and foremost, the machine's cutting accuracy is paramount. Look for machines that offer adjustable blade settings and advanced technology that minimizes deviation in the cut. This is especially important for industries that require high precision in their products, as even minor inaccuracies can impact overall quality.

Another criteria to consider is the machine's throughput. A high-speed slitting machine can significantly enhance operational efficiency, reducing downtime and maximizing output. Additionally, ease of operation and maintenance should not be overlooked. Machines that feature user-friendly interfaces and require minimal maintenance will save time and reduce the likelihood of interruptions in production.

**Tips:** Always verify the warranty and customer support offered with the machine. This can provide peace of mind and ensure that you have assistance when needed. Consider visiting trade shows or industry exhibitions to see the machines in action and gather firsthand information from manufacturers and users alike. This experience can offer valuable insights into the performance and reliability of different models.

Detailed Review of the Top 10 HR Slitting Machines

In 2023, the market for HR slitting machines is witnessing a transformation driven by advancements in technology and the increasing demand for precision and efficiency in manufacturing. According to a recent industry report, the global slitting machine market is expected to grow at a CAGR of 5.2%, reaching a valuation of $1.9 billion by 2027. This growth is fueled by the expanding applications of slitting machines across various sectors, including automotive, packaging, and textiles, where precision cutting is crucial.

Among the top contenders in this sector, the latest models of HR slitting machines stand out due to their innovative features designed to optimize performance. Enhanced cutting systems with advanced blade technologies offer improved accuracy while reducing material waste. Furthermore, automation integration in these machines significantly cuts down operational time and labor costs, aligning with the increasing emphasis on operational efficiency across industries. According to data from a leading manufacturing analysis firm, 85% of companies reported increased productivity after upgrading to modern slitting technologies.

The detailed review of the top 10 HR slitting machines for 2023 highlights the growing trend toward user-friendly interfaces and real-time performance monitoring. With the rising focus on Industry 4.0, manufacturers are looking for machines that not only deliver precise cuts but also provide valuable insights into their operational metrics. The future of HR slitting machines seems poised to enhance manufacturing capabilities while being more adaptable to ever-evolving production needs.

Comparison of Precision and Efficiency Metrics in HR Slitting

When assessing HR slitting machines in 2023, precision and efficiency metrics play a crucial role in determining the best options available in the market. Precision refers to the machine's ability to deliver consistent and exact cuts, which is essential in maintaining the integrity of the processed material. Efficiency, on the other hand, is measured by the machine's speed and energy consumption during operation. A well-balanced combination of these metrics will enhance production workflows while minimizing waste, ultimately leading to improved cost-effectiveness.

To achieve optimal results, consider the following tips: First, regularly calibrate your slitting machine to ensure that it maintains its cutting precision. This helps reduce material waste and improves product quality. Second, look for machines with advanced automation features that can adapt to varying material thicknesses and types, as this can significantly enhance efficiency. Finally, analyze the long-term operational costs associated with energy consumption and maintenance, as these can impact overall productivity and profitability.

Emphasizing the comparison of precision and efficiency metrics across different models can guide operators in selecting equipment that not only meets their specific requirements but also enhances their production capabilities. Understanding the trade-offs between speed and accuracy will empower manufacturers to make informed decisions that align with their operational goals.

Top 10 HR Slitting Machines for Precision and Efficiency in 2023

| Machine Model | Cutting Width (mm) | Max Speed (m/min) | Precision (mm) | Efficiency Rating (%) |

|---|---|---|---|---|

| Model A | 1500 | 200 | 0.05 | 98 |

| Model B | 1600 | 180 | 0.04 | 96 |

| Model C | 1400 | 220 | 0.06 | 92 |

| Model D | 1550 | 190 | 0.05 | 95 |

| Model E | 1450 | 175 | 0.03 | 97 |

| Model F | 1600 | 210 | 0.02 | 99 |

| Model G | 1500 | 200 | 0.07 | 93 |

| Model H | 1400 | 185 | 0.04 | 95 |

| Model I | 1550 | 175 | 0.05 | 94 |

| Model J | 1600 | 190 | 0.03 | 99 |

Future Trends in HR Slitting Technology and Innovations

The future of HR slitting technology is poised for significant advancements, driven by the need for enhanced precision and efficiency in manufacturing processes. One of the most notable trends is the integration of automation and smart technologies. With the rise of Industry 4.0, slitting machines are becoming more interconnected, allowing for real-time monitoring and data analytics. This enables operators to optimize the slitting process by adjusting parameters on the fly, thereby reducing waste and improving product quality.

Another critical innovation on the horizon is the development of high-speed slitting systems that employ advanced blade materials and designs. These machines are designed to achieve tighter tolerances and superior edge quality, catering to industries that require intricate and delicate cutting operations. Moreover, the implementation of artificial intelligence in predictive maintenance will play a vital role in minimizing downtime and enhancing the overall reliability of slitting machines. By anticipating potential equipment failures before they occur, manufacturers can enhance productivity and maintain continuous operations, which is crucial in today’s fast-paced market.

Top 10 HR Slitting Machines for Precision and Efficiency in 2023

This chart illustrates the cutting speed (meters per minute) and precision (tolerance in mm) of the top 10 HR slitting machines in 2023, showing the latest trends in technology and innovations in the industry.

Related Posts

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

What is a Roller Leveling Machine and How Does It Work?

-

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines