2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

The steel industry is undergoing a transformative phase, driven by the relentless pursuit of sustainability and innovation. With the global steel production expected to reach 2.16 billion metric tons in 2025, as reported by the World Steel Association, manufacturers are increasingly turning to advanced technology and machinery to stay competitive. Among these advancements, steel mill machines are at the forefront, serving as the backbone of production processes that aim to optimize output while reducing costs and energy consumption.

In the past few years, rapid developments in automation, data analytics, and artificial intelligence have led to the emergence of cutting-edge steel mill machines. For instance, the integration of Industry 4.0 technologies has allowed steel plants to enhance their operational efficiency by up to 30%, according to a recent study by McKinsey & Company. These innovations not only improve the quality of steel produced but also contribute significantly to minimizing waste and environmental impact, aligning the industry with global sustainability goals.

As we look towards 2025 and beyond, the evolution of steel mill machines promises to redefine production standards and operational paradigms. This article explores the top five steel mill machines that are revolutionizing the industry today, shedding light on their functionalities, benefits, and the pivotal role they play in shaping the future of steel manufacturing.

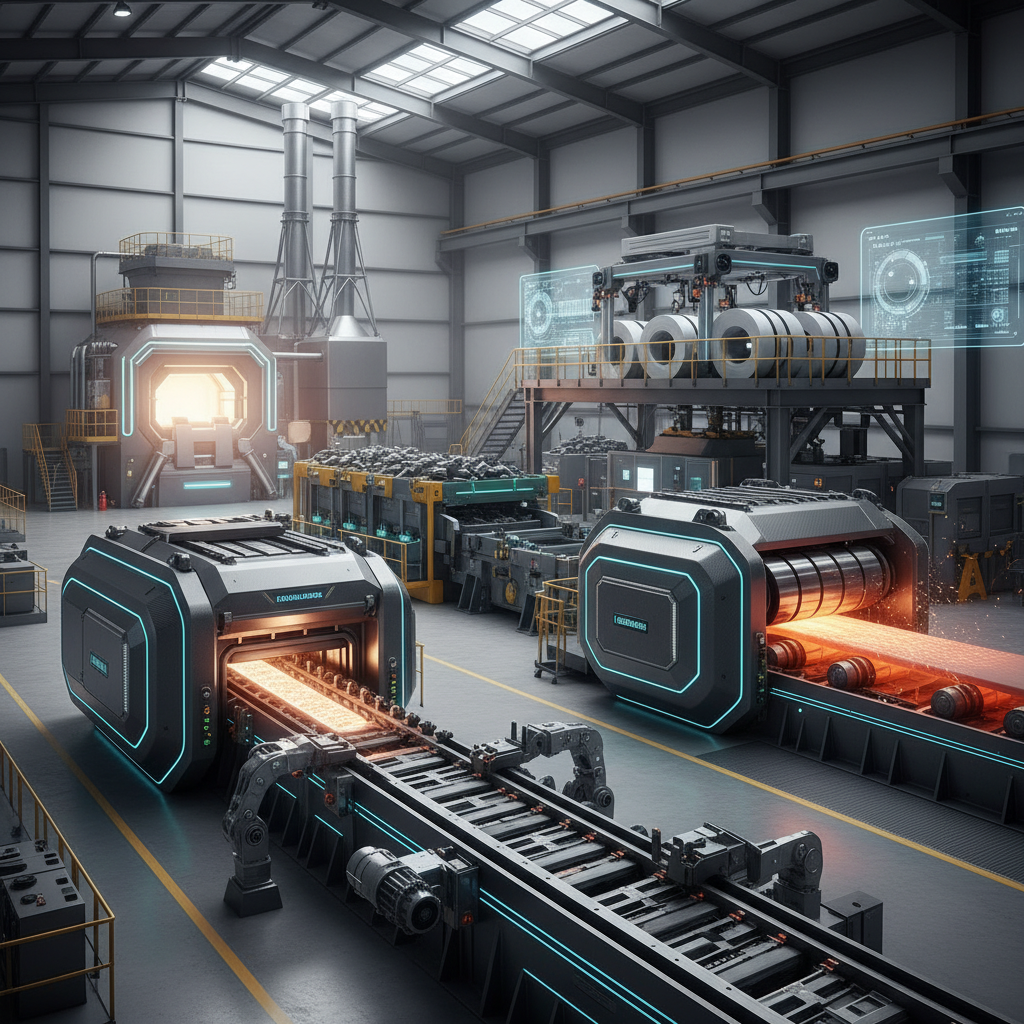

Innovative Automation Technologies Reshaping Steel Mill Operations

The steel manufacturing industry is on the cusp of a major transformation, largely driven by innovative automation technologies. As demands for efficiency and production quality increase, steel mills are increasingly implementing sophisticated automated systems. According to a recent report, the global market for steel mill automation is projected to grow at a compound annual growth rate (CAGR) of 8.5% through 2026. This growth is fueled by advancements in artificial intelligence and machine learning algorithms that optimize operations, reduce waste, and improve safety.

One of the standout innovations reshaping the sector is the implementation of advanced robotics for material handling and processing. These systems not only increase operational efficiency but also minimize human error in hazardous environments. Additionally, smart sensors integrated into machinery gather real-time data, allowing for predictive maintenance and significantly reducing downtime. As competition intensifies, companies that adopt such cutting-edge technologies gain a substantial edge, enhancing their overall productivity and market responsiveness.

The emergence of autonomous systems in logistics, particularly for steel production, signifies another leap forward. Automating freight handling with robotic technologies addresses the complexities of transporting raw materials and finished products. This shift not only streamlines the supply chain but also contributes to a sustainable production model, aligning with the industry's goals for greener practices. By embracing these advanced automation technologies, steel mills are not only revolutionizing their operations but also setting new benchmarks for the entire manufacturing landscape.

Cutting-Edge Smelting Equipment Enhancing Efficiency and Sustainability

The steel industry is undergoing a significant transformation, primarily driven by advancements in cutting-edge smelting equipment. As outlined in the "World Steel Association's 2022 report," energy efficiency in steel production has improved by an impressive 24% over the past decade due to innovations in technology. Modern smelting machines are not only enhancing production speeds but also reducing carbon emissions, which aligns perfectly with global sustainability goals. For instance, electric arc furnaces (EAFs) have become increasingly popular, as they use up to 90% recycled steel and emit 75% less CO2 compared to traditional blast furnaces.

Moreover, the integration of automation and AI into smelting processes has led to more precise control of operations, resulting in optimized material usage and waste reduction. According to a 2023 McKinsey report, the implementation of smart smelting technology could potentially increase productivity by up to 30% while cutting down overall costs significantly. As steel mills invest in these revolutionary machines, the focus on enhancing efficiency and sustainability will be paramount, ultimately reshaping the industry's environmental impact and economic viability for the future.

Advanced Rolling Mill Machinery Transforming Product Quality

The steel industry is witnessing a remarkable evolution with the introduction of advanced rolling mill machinery that significantly enhances product quality. These innovations not only improve the structural integrity of steel products but also ensure consistency across production lines. With technology advancing, mills are utilizing high-precision rolling techniques, resulting in finer surface finishes and superior mechanical properties. This transformation is essential for meeting modern demands in construction, automotive, and manufacturing sectors.

Tips for maximizing the benefits of advanced rolling mill machinery include investing in regular training for operators to fully leverage new features and functionalities. Additionally, maintaining machine calibration and performing routine maintenance can prevent downtime and ensure optimal performance. Companies should also consider integrating data analytics systems that track production quality and machine efficiency, paving the way for continuous improvement.

As the industry adapts to these changes, businesses that embrace cutting-edge rolling mill technologies will stand out in a competitive market. With improvements in material yield and waste reduction, the path forward is not just about enhancing production capabilities but also about promoting sustainability in steel manufacturing.

Smart Data Analytics Tools for Real-Time Steel Production Monitoring

In the fast-evolving steel industry, smart data analytics tools play a crucial role in real-time production monitoring, significantly enhancing operational efficiency. These innovative technologies enable steel mills to collect and analyze vast amounts of data from various sources, ensuring that production processes are streamlined and responsive. By harnessing advanced algorithms and machine learning, manufacturers can predict maintenance needs, optimize workflow, and reduce downtime, thus driving productivity to new heights.

Moreover, these analytics tools empower mill operators to make informed decisions quickly. Real-time insights allow for immediate identification of inefficiencies or quality issues, enabling prompt corrective actions. This proactive approach not only saves time but also minimizes waste and improves product consistency. As the steel industry continues to embrace digital transformation, the integration of smart data analytics tools is essential for staying competitive in a landscape that demands agility and innovation.

Eco-Friendly Steel Processing Machines Addressing Environmental Challenges

In recent years, the steel mill industry has faced increasing pressure to reduce its environmental impact. Innovations in eco-friendly steel processing machines have emerged as a solution to address pressing environmental challenges. These machines utilize new technologies and materials that significantly lower emissions and energy consumption, making the steel production process more sustainable.

One notable advancement is the development of electric arc furnaces that are powered by renewable energy sources. These furnaces not only reduce greenhouse gas emissions but also allow for better recycling of scrap steel, minimizing waste. Furthermore, advancements in water treatment systems within steel mills ensure that water used in production is recycled and does not pollute local ecosystems.

As industries worldwide strive for sustainability, the adoption of these eco-friendly machines represents a pivotal step toward a cleaner future in steel manufacturing. By embracing technologies that prioritize environmental responsibility, steel mills can meet both industry standards and societal expectations for greener operations.

2025 Top 5 Eco-Friendly Steel Processing Machines

This chart illustrates the estimated efficiency improvements and CO2 reduction potential of the top 5 eco-friendly steel mill machines in 2025. These machines are designed to address environmental challenges while enhancing production capacity.

Related Posts

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions