Top 5 Best Coil Slitting Machines for Precision Cutting in 2026?

In the evolving landscape of manufacturing, precision is paramount. The coil slitting machine is a vital tool for achieving high precision in metal processing. These machines are designed to cut large coils of metal into narrower strips. Each blade must be finely tuned to ensure accuracy.

Selecting the right coil slitting machine can be challenging. Features vary significantly among models. Some machines excel in speed, while others might prioritize precision. Users often face dilemmas when balancing these features. A machine that cuts quickly may sacrifice edge quality, leading to waste.

The urgency of making informed choices grows as industries expand. Investing in a high-quality coil slitting machine means better productivity and less downtime. In this review, we will explore the top five models of 2026. We aim to assist manufacturers in navigating their options for enhanced efficiency and precision.

Top 5 Coil Slitting Machines for Precision Cutting in 2026

In 2026, the demand for precision cutting in the manufacturing industry has increased. Many companies now seek the best coil slitting machines. These machines are essential for cutting metal coils into precise widths. A well-chosen machine can enhance production efficiency. However, selecting the right one is often a challenge.

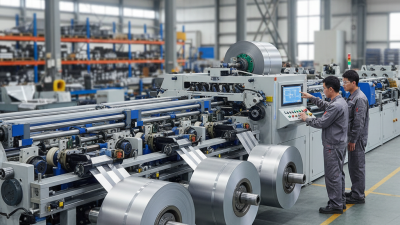

Some models lack the versatility needed for different materials. They may struggle with thicker coils or high-speed operations. This can lead to delays and increased costs. Operators often report difficulties when changing settings between jobs. The learning curve on some machines can be steep, causing frustration. Investing in training may be necessary, but this adds to overall operational expenses.

Moreover, maintenance plays a crucial role in performance. Machines that are not regularly serviced may exhibit precision issues over time. Users have noted problems with blade wear and alignment. This can result in poor cutting quality. Regular inspection is needed, but it might not always be prioritized by busy teams. Finding the right balance between precision, cost, and user-friendliness remains a key consideration.

Top 5 Coil Slitting Machines for Precision Cutting in 2026

| Machine Model | Cutting Width (mm) | Max Speed (m/min) | Material Thickness (mm) | Precision Tolerance (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 1300 | 200 | 0.2 - 3.0 | ±0.02 | 1500 |

| Model B | 1600 | 250 | 0.15 - 2.5 | ±0.01 | 1800 |

| Model C | 1400 | 220 | 0.5 - 4.0 | ±0.03 | 1600 |

| Model D | 1200 | 240 | 0.2 - 3.5 | ±0.02 | 1400 |

| Model E | 1250 | 230 | 0.1 - 2.0 | ±0.015 | 1550 |

Overview of Coil Slitting Technology and Its Industry Applications

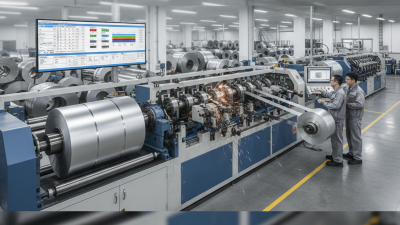

Coil slitting technology plays a crucial role in various industries, particularly in metal processing. This process allows manufacturers to cut large rolls or coils of material into narrower strips. These strips can be used in numerous applications, from automotive components to appliance parts. Data from industry reports indicate that the demand for precision slitting is increasing, driven by needs for efficiency and accuracy.

The process involves several steps, including unwinding the coil, feeding it through a slitting machine, and rewinding the resulting strips. According to recent statistics, about 35% of manufacturers consider precision a top priority. In a market projected to grow by over 6% annually until 2028, the adoption of advanced coil slitting machines is vital. Yet, many companies struggle with outdated technology. Their inefficiencies lead to waste, costing them significantly.

Investing in modern slitting machinery can mitigate these challenges. The right technology enhances accuracy and reduces setup times. However, not every company can afford these upgrades. Some facilities lag behind and fail to meet production demands. They risk losing market share to competitors who innovate. Analyzing these shortcomings is essential for future growth and sustainability in the coil slitting industry.

Key Features to Consider When Selecting a Coil Slitting Machine

When selecting a coil slitting machine, precision is key. Accuracy in cutting significantly affects the quality of your end product. Look for machines that offer adjustable slitting clearance. This feature ensures fine-tuned cuts according to material thickness. Operators should remember that an overly complex setup can lead to mistakes.

Another essential feature is the machine's speed. Find a balance between speed and quality. High-speed options might seem appealing, but they could result in errors if not monitored properly. Speed should complement precision, not compromise it.

Tips: Regular maintenance is crucial. A well-maintained machine runs smoother and lasts longer. Additionally, consider user-friendly interfaces. A tough-to-navigate control panel can frustrate operators.

Lastly, think about the blade materials. Quality blades reduce wear and tear. Poor blade choices lead to frequent replacements and downtime. Reflect on the long-term costs of your decisions. Each feature chosen can impact overall efficiency. Choose wisely, and don’t rush the selection process.

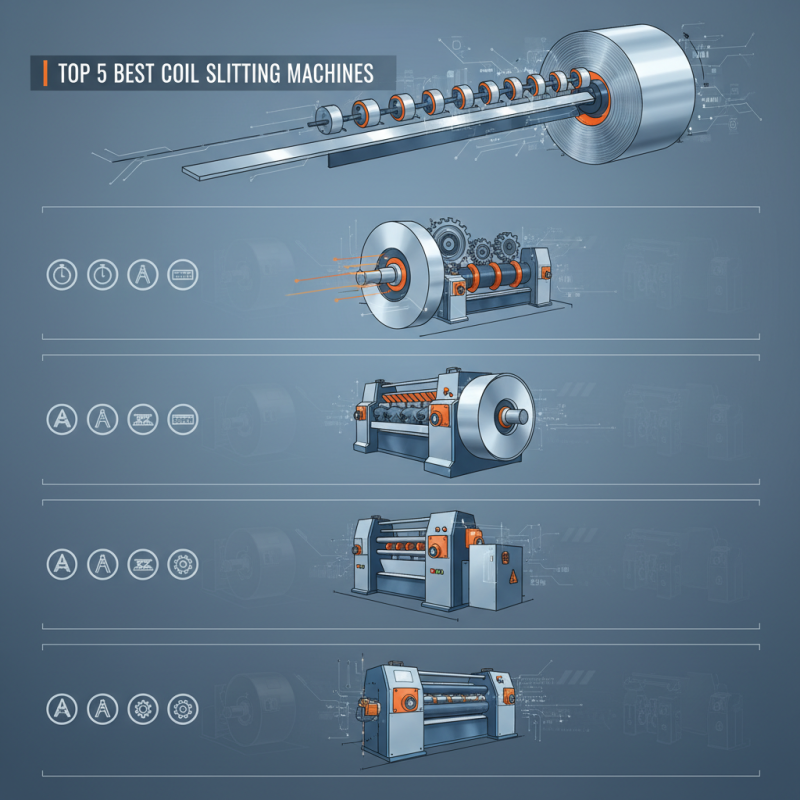

Top 5 Best Coil Slitting Machines for Precision Cutting in 2026

This chart displays the cutting precision of the top 5 coil slitting machines for 2026. It is crucial to consider precision when selecting a machine for optimal performance in coil processing.

Comparative Analysis of Leading Coil Slitting Machines on the Market

When choosing a coil slitting machine, precision is essential. Several machines stand out in today's market. Comparing their features can guide your decision. Focus on cutting accuracy, speed, and ease of use. Each machine varies in design and technology. Some may perform well but lack user-friendly interfaces.

Tips: Consider the type of material you'll be slitting. Some machines excel with thicker coils, while others are designed for thinner sheets. Compatibility with your existing setup is crucial.

Price point is also a factor. An expensive machine may not always guarantee superior performance. Look for reviews and real user feedback. Reliable data can help you avoid costly mistakes. Remember, a machine that works well for one is not guaranteed to work for all.

Buying the right coil slitting machine requires careful thought. Rushing this decision can lead to issues down the line. Assess your production needs and expected outputs carefully. Take your time to research and analyze.

Performance Metrics: Precision and Tolerance Levels in Slitting Machines

In the realm of coil slitting machines, precision and tolerance are pivotal. The cutting process directly impacts product quality. Recent industry reports indicate that machines with a tolerance level of ±0.1 mm are becoming the standard. This precision is crucial for manufacturers who rely on tight specifications. A slight deviation can lead to significant quality issues.

Performance metrics reveal that machines designed for high precision often utilize advanced technology. Many models now feature laser alignment systems. These systems enhance cutting accuracy and reduce waste. Data shows that slitting machines with precision control can minimize material loss by 20%. However, human error still presents a challenge. Operators must remain vigilant during setup procedures.

Moreover, the capacity for these machines can vary widely. Some may handle materials as thin as 0.05 mm, while others manage thicker gauges. This variability can lead to inconsistencies in production. While advancements in technology improve precision, the need for skilled operators is paramount. Training programs can help address this gap, ensuring better outcomes in high-stakes environments. Precision in slitting machines is indispensable for meeting modern manufacturing demands.

Conclusion

In the rapidly evolving field of manufacturing, the selection of the right coil slitting machine is paramount for ensuring precision cutting in various industrial applications. This article examines the top five coil slitting machines expected to lead the market in 2026, emphasizing the importance of understanding coil slitting technology. Key features to consider include cutting precision, tolerance levels, and adaptability to different materials, which play a crucial role in operational efficiency.

Additionally, the comparative analysis reveals performance metrics that can guide manufacturers in choosing the best equipment suited for their needs. With a focus on innovations and advancements, the article highlights future trends in coil slitting machines, showcasing how emerging technologies are set to enhance productivity and accuracy in the industry. By staying informed about these developments, manufacturers can better position themselves to meet the demands of a competitive market.

Related Posts

-

Top 10 Benefits of Using Stainless Steel Slitting Machines for Your Business

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Top Benefits of Using a Metal Coil Slitting Machine in Manufacturing Industry?

-

What is a Sheet Metal Slitting Machine and How Does It Work?

-

Coil Cut to Length Machine Tips for Optimal Performance?