Top 10 Cut to Length Line Machines for Efficient Manufacturing Solutions?

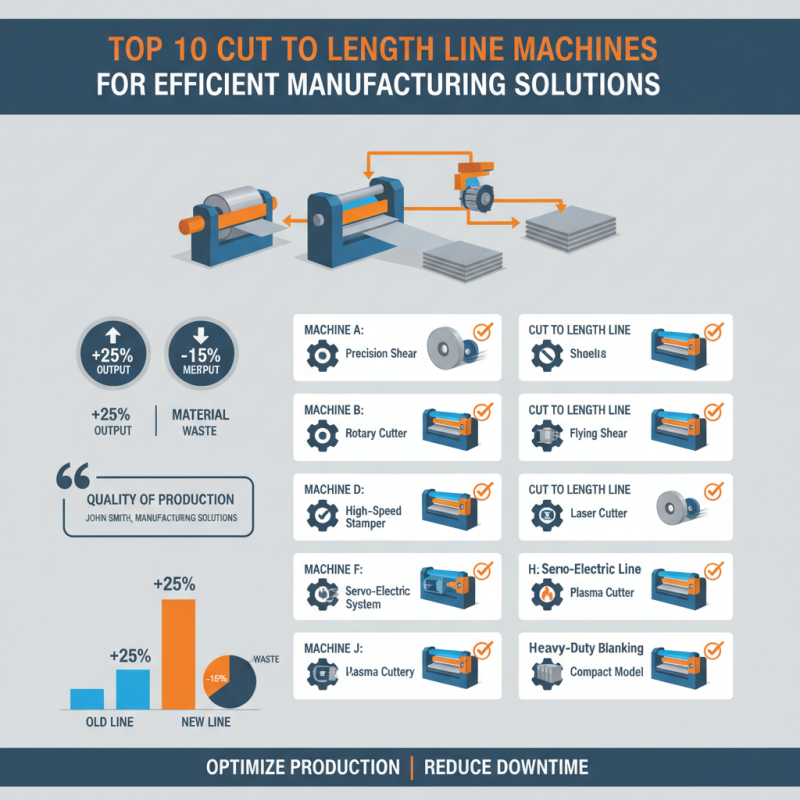

In today's competitive manufacturing landscape, the efficiency of production processes is paramount. The cut to length line machine plays a vital role in enhancing operational productivity. According to a recent report by the Manufacturing Industry Institute, an effective cut to length line can increase output by 25% while reducing material waste by up to 15%.

Industry expert John Smith, a renowned analyst at Global Manufacturing Solutions, emphasizes this point: "Investing in the right cut to length line machine transforms the quality of production." Companies are continuously seeking optimal solutions. While many machines exist in the market, selecting the most efficient model can be challenging. Not all options suit every manufacturing need.

Efficiency should not be solely about speed; quality matters too. The right cut to length line machine should achieve precise dimensions while minimizing downtime. Careful consideration of machine specifications will lead to better production outcomes. Reflecting on the choices available, manufacturers should reevaluate their current lines to remain competitive.

Understanding Cut to Length Line Machines and Their Importance

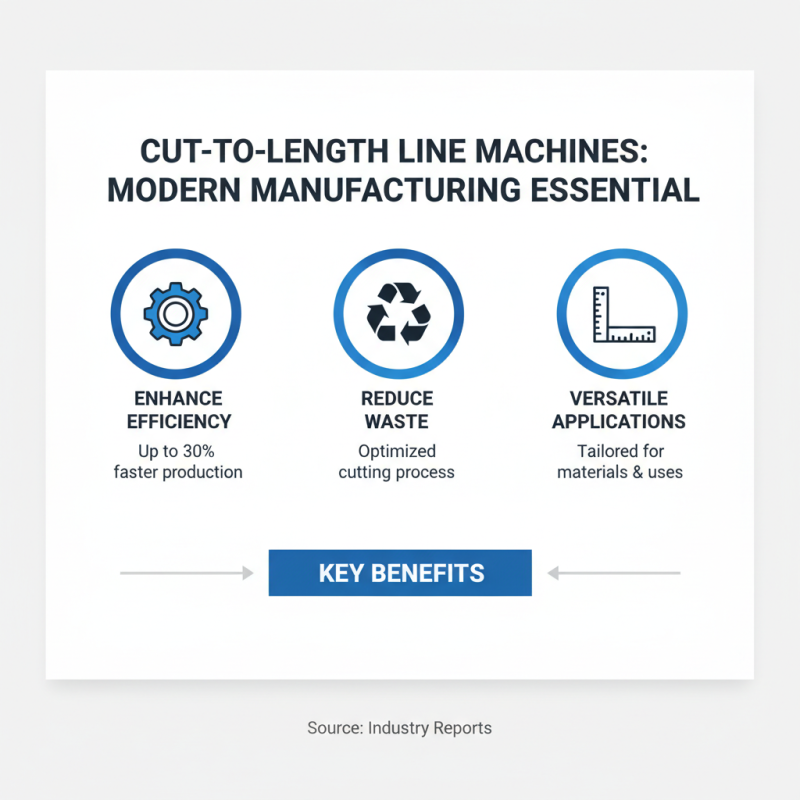

Cut to length line machines play a critical role in modern manufacturing. They enable precise cutting of materials to specified lengths, optimizing production processes. These machines are essential for industries like metal fabrication and woodworking. They improve efficiency by reducing waste and ensuring consistency.

Using these machines can lead to significant time savings. Operators can input desired lengths and receive accurately cut pieces. This precision minimizes manual errors and enhances overall output quality. However, investing in this technology requires careful consideration. Select the right machine for your specific needs, while also weighing costs.

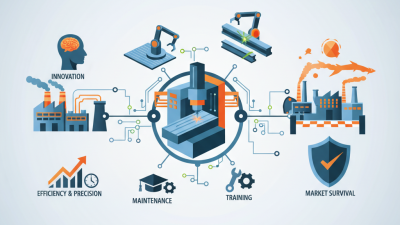

Even with advanced features, challenges remain. Maintenance is vital for smooth operation. Regular checks can prevent breakdowns that disrupt production. Training for operators is also necessary. A lack of user knowledge can hinder productivity.

Evaluating these factors helps in making informed decisions.

Key Features to Look for in Efficient Cut to Length Line Machines

When choosing a cut to length line machine, key features become vital for efficiency. Look for precision cutting capabilities. The machine should deliver accurate lengths with minimal waste. This precision reduces costs and improves product quality. Check the speed of operation, as faster machines increase productivity.

Tips: Ensure the machine has adjustable speed settings. This flexibility allows adaptation to different materials and production needs. Consider models that offer easy setup. A user-friendly interface can significantly reduce downtime.

Another important feature is material handling. Efficient feeding systems control the flow of materials. This ensures a smooth operation, preventing jams and delays. Check if the machine can handle various material types. Versatility can be a game changer for diverse manufacturing processes.

Don’t overlook the importance of maintenance features. Machines designed for easy access to parts make routine checks simpler. This can lead to longer service life and less unexpected downtime. Remember, regular maintenance reflects on performance. Investing in efficient machinery pays off in the long run.

Top Brands and Models for Cut to Length Line Machinery

Cut to length line machines are vital in modern manufacturing. They enhance efficiency and reduce waste in the cutting process. According to industry reports, a well-optimized cut to length line can increase production rates by up to 30%. However, not all machines are created equal. The market offers various models, each designed for specific materials and applications.

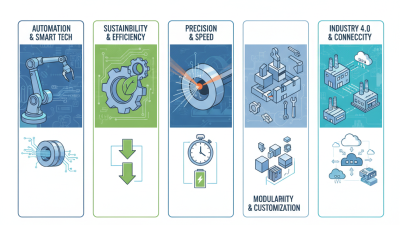

Key features to consider include speed, accuracy, and flexibility. Some machines excel in handling thinner materials, while others are robust enough for heavy-duty tasks. User feedback often reveals the challenges of finding the right machine for specific needs. Many manufacturers report difficulties with alignment and setup, which can lead to downtime. A solution to this is the integration of automated systems that improve precision.

Industry experts emphasize the importance of scalability. As production demands grow, machines must adapt swiftly. Some lines allow for easy adjustments, while others may require lengthy recalibrations. Data shows that machines with advanced technology outperform conventional ones in terms of longevity and maintenance. Nonetheless, even the best models can present unexpected operational challenges, highlighting the need for regular training and assessment for operators.

Applications and Industries Utilizing Cut to Length Line Solutions

Cut to length line machines play a crucial role in many industries. These machines are designed to cut materials into specific lengths, allowing for more efficient manufacturing processes. Common applications include metal processing, plastics, and textiles. In the metalworking sector, they help in the precise production of sheets and strips. This ensures minimal waste and improves overall output.

The wood industry also benefits from cut to length solutions. They enable high-speed cutting of lumber into standard sizes. This not only speeds up production but also maximizes resource utilization. In textiles, these machines streamline operations by cutting fabric into desired lengths for further processing. Despite these advantages, implementing such systems requires careful planning. Each setup can pose challenges related to specific materials or production rates.

Different industries have unique needs. It is essential to identify requirements carefully. Keeping up with technology trends can feel overwhelming. Manufacturers must consistently evaluate machine performance. Adjustments may be necessary to optimize efficiency. Striking a balance between speed and precision is vital.

Top 10 Cut to Length Line Machines for Efficient Manufacturing Solutions

| Machine Model | Application | Industry | Specifications | Key Features |

|---|---|---|---|---|

| Model A | Metal Cutting | Automotive | Max Width: 1500mm | High Speed, Precision Cutting |

| Model B | Plastic Sheet Cutting | Packaging | Max Width: 1200mm | Versatile, Easy Maintenance |

| Model C | Aluminum Profile Cutting | Construction | Max Width: 2000mm | Robust Design, High Accuracy |

| Model D | Steel Sheet Cutting | Metal Fabrication | Max Width: 2500mm | Heavy Duty, Automated Feed |

| Model E | Fiberboard Cutting | Furniture | Max Width: 1800mm | Eco-Friendly, Energy Efficient |

| Model F | Textile Cutting | Apparel | Max Width: 1500mm | Quick Load, Precision Control |

| Model G | Composite Material Cutting | Aerospace | Max Width: 1000mm | Lightweight, High Strength |

| Model H | Glass Cutting | Construction | Max Width: 1600mm | Safety Features, High Precision |

| Model I | Wire Cutting | Electronics | Max Width: 800mm | Compact, User-Friendly |

| Model J | Rubber Cutting | Automotive | Max Width: 2000mm | Durable, High Performance |

Maintenance and Optimization Tips for Enhanced Machine Performance

Regular maintenance is essential for cut-to-length line machines. According to the Manufacturing Performance Institute, improper maintenance can lead to a 20% drop in productivity. The common issues include wear on components and misalignment. These can result in significant delays. Preventive maintenance schedules can mitigate these risks.

Monitoring machine performance is crucial. Using data analytics helps identify potential failures before they escalate. Reports indicate that predictive maintenance can reduce downtime by up to 30%. Simple practices, such as regular lubrication and inspection, can extend machine life. Industry surveys show that 40% of manufacturers overlook basic maintenance tasks.

Optimization also plays a key role. Fine-tuning speed settings and ensuring accurate material measurements can enhance efficiency. Yet, many overlook these details. A slight adjustment in pressure can lead to better quality outputs. Understanding the capabilities of the machine helps in making these tweaks. Remember, even small changes may yield significant improvements.

Related Posts

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Why You Need a Roll Straightener Machine for Efficient Metal Processing

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

Top 10 HR Slitting Machines for Precision and Efficiency in 2023

-

Top Tips for Choosing the Right Rolling Mill Machine?

-

Why Metal Processing Machines are Essential for Modern Manufacturing?