2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

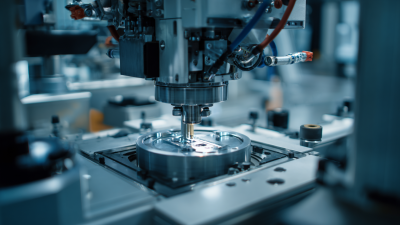

In the rapidly evolving landscape of manufacturing, the efficiency of production processes is paramount. As industries strive to optimize their operations, "cut to length machines" have emerged as essential tools, offering precision and speed in material processing.

John Smith, a leading expert in manufacturing technology, emphasizes the significance of these machines, stating,

"The right cut to length machine can drastically reduce waste and increase productivity, making it a cornerstone of modern manufacturing."

In the rapidly evolving landscape of manufacturing, the efficiency of production processes is paramount. As industries strive to optimize their operations, "cut to length machines" have emerged as essential tools, offering precision and speed in material processing.

John Smith, a leading expert in manufacturing technology, emphasizes the significance of these machines, stating,

"The right cut to length machine can drastically reduce waste and increase productivity, making it a cornerstone of modern manufacturing."

As we look ahead to 2025, the demand for advanced cut to length machines is expected to rise, driven by the need for quicker turnaround times and enhanced operational efficiency. Manufacturers are increasingly recognizing that investing in state-of-the-art equipment can lead to substantial gains in both performance and profitability. This guide will explore the

top 10 cut to length machines set to revolutionize manufacturing solutions in the coming years, highlighting features that cater specifically to the needs of today’s dynamic industries.

Understanding the capabilities and innovations within this sector is crucial for businesses aiming to stay competitive. With insights from industry leaders and detailed reviews of the most efficient machines, we provide a comprehensive overview that equips manufacturers with the knowledge necessary to make informed decisions in their production processes.

Top Innovations in Cut to Length Machine Technology for 2025

As we look ahead to 2025, the cut to length machine technology is on the brink of remarkable advancements that promise to transform manufacturing processes. According to a market research study published by Custom Market Insights, the CNC (Computer Numerical Control) machine market is expected to grow significantly, with a projected value of $101.22 billion in 2025, reaching $195.59 billion by 2032 at a compound annual growth rate (CAGR) of 9.9%. This growth is driven by innovations in precision cutting technologies and automation that enhance efficiency and reduce waste.

The future of cut to length machines lies in their ability to integrate advanced AI algorithms, which streamline operations and improve decision-making processes. For instance, the implementation of AI-driven analytics not only optimizes cutting patterns but also predicts maintenance needs, reducing downtime and costs. To maximize the benefits of these innovations, manufacturers should consider investing in training for their personnel, ensuring they are well-versed in operating these high-tech machines.

Tips: Embrace the digital transformation by exploring software solutions that complement cut to length machines. Additionally, staying informed about emerging technologies is crucial for maintaining a competitive edge in the industry. As new standards and innovations emerge, being adaptable will enable businesses to leverage technology effectively and enhance their manufacturing capabilities.

Key Features to Consider When Selecting Cut to Length Machines

When selecting cut to length machines for your manufacturing needs, several key features should be considered to ensure efficiency and reliability. Firstly, the machine's cutting precision is vital. Look for machines that offer adjustable settings for cutting length and that maintain consistent accuracy across various production runs. This precision not only reduces material waste but also enhances product quality, leading to better overall performance.

Tip: Always evaluate the machine's capacity in terms of the materials it can handle. Ensure it can process the thickness and type of material you intend to use, as this will directly impact both efficiency and output quality. Additionally, consider the machine's speed and cycle time to maximize productivity.

Another critical aspect is the machine's ease of operation and maintenance. Opt for machines that feature user-friendly controls and automated settings for smoother workflows. Regular maintenance needs should also be outlined clearly, as machines that require excessive downtime can hinder production schedules.

Tip: Investing in a machine with good customer support and readily available replacement parts will minimize disruptions to your manufacturing process and keep your operations running smoothly.

Comparative Analysis: Leading Brands in Cut to Length Machinery

The cut-to-length machinery market is undergoing significant advancements, driven by the increasing demand for efficient manufacturing solutions across various industries.

As projected, the global fabric cutting machine market is poised to expand from USD 3.847 billion in 2025 to USD 6.954 billion by 2035, suggesting a robust annual growth rate.

This growth can be attributed to the rising need for precision and speed in production lines, which these machines efficiently fulfill.

Leading brands in cut-to-length machinery are focusing on innovative technologies and automation to enhance operational efficiency. As the metal fabrication equipment market also steadily grows, with expectations to reach substantial values by 2032, manufacturers are increasingly investing in high-performance equipment.

This trend indicates a shift towards upgrading older systems to meet the modern demands of speed and accuracy, further solidifying the competitive landscape among top machinery brands. With continual technological enhancements and market expansions, the cut-to-length machinery sector remains a focal point for manufacturers seeking to optimize their production capabilities.

Efficiency Metrics: Assessing the Performance of 2025's Best Machines

In 2025, the landscape of manufacturing efficiency is set to be transformed by the introduction of advanced cut to length machines. These machines are evaluated based on key efficiency metrics such as throughput, energy consumption, and waste reduction. According to a report by the Manufacturing Technology Association, the latest models have demonstrated a potential increase in throughput rates by up to 30%, significantly reducing cycle times and maximizing productivity. This improvement is essential as manufacturers strive to meet the increasing demands for customized products without compromising on delivery timelines.

Moreover, energy efficiency is becoming a focal point in the design of these machines. The International Energy Agency notes that energy-efficient manufacturing can reduce operational costs by up to 15%. Newer cut to length machines now incorporate smart technology that optimizes energy usage during production processes. By analyzing real-time data, these machines adjust their operational parameters to minimize energy consumption while maintaining output quality. Additionally, advancements in materials handling and automation contribute to lowering material waste, which not only improves profit margins but also supports sustainable manufacturing practices, crucial in today’s environmentally-conscious market.

Future Trends in Cut to Length Manufacturing Processes and Solutions

The manufacturing landscape is undergoing a significant transformation driven by advancements in technology, particularly in cut to length processes. As we approach 2025, the integration of artificial intelligence (AI) into manufacturing is poised to redefine efficiency and productivity. AI enables manufacturers to optimize their operations through predictive analytics, leading to reduced waste and improved material utilization. This shift not only streamlines the cut to length processes but also enhances overall manufacturing workflows, making them more agile and responsive to market demands.

Moreover, the Internet of Things (IoT) is emerging as a pivotal trend in enhancing cut to length manufacturing solutions. By connecting machines and monitoring processes in real-time, manufacturers can achieve greater insights into their operations, allowing for immediate adjustments and proactive maintenance. This connectivity fosters a more data-driven environment where informed decision-making becomes the norm.

As we look to the future, it is clear that the fusion of AI and IoT will play a crucial role in shaping the efficiency and flexibility of cut to length manufacturing, driving the industry toward a more innovative and sustainable future.