Top Tips for Choosing the Right Rolling Mill Machine?

Choosing the right rolling mill machine can significantly impact your production efficiency. According to industry expert John Smith, "A well-chosen rolling mill can enhance product quality." When selecting a rolling mill machine, consider various factors.

Think about your specific needs. What materials will you process? Different machines suit different metals. The choice of size and capacity matters too. A small mill may not handle larger jobs effectively. Additionally, cost is a critical consideration. While expensive models might offer advanced features, budget options can also fulfill basic requirements.

Don't overlook the importance of durability and maintenance. A reliable rolling mill machine should withstand daily wear. Reflecting on prior experiences, many have found that cheaper models lead to frequent repairs. This can disrupt production and impact profitability. Thus, balancing quality and cost is essential for long-term success.

Understanding the Different Types of Rolling Mill Machines

When choosing a rolling mill machine, understanding the different types available is crucial. There are several categories, including flat rolling mills, wire mills, and tube mills. Each type serves specific functions, catering to various materials like steel, aluminum, and copper. The global rolling mill market was valued at approximately $4.5 billion in 2022 and is projected to grow steadily over the years, indicating increasing demand.

Flat rolling mills dominate the industry due to their versatility. They can produce sheets of various sizes, vital for construction and automotive sectors. A report from a leading materials science journal states that flat-rolled products account for over 70% of the total rolled metal production. However, businesses should consider the operational costs and energy consumption associated with these machines.

Wire mills, on the other hand, focus on producing wire products, essential in electrical applications and manufacturing. According to industry data, the wire and cable market is set to exceed $250 billion by 2026. A possible drawback is the limited production capabilities for thicker materials. Each type of rolling mill presents unique benefits and challenges, illustrating the importance of a careful assessment of operational needs before making a choice.

Key Factors to Consider When Choosing a Rolling Mill

When choosing a rolling mill machine, several key factors deserve attention. First, the type of materials you plan to process is crucial. According to industry reports, over 40% of equipment failures stem from material mismatch. Know your materials well. Analyze the specific strength and ductility characteristics. Not every mill handles every material efficiently.

Another important aspect is the mill's capacity. Some mills can process more than 200 tons per hour, while others may only manage 10 tons. Assess your production needs accurately. If your demand increases, a mill that operates below capacity may hinder your growth. Remember, investing in a high-capacity machine can save money in the long run.

Consider the cost and maintenance of the equipment, too. Recent studies show that maintenance costs can account for up to 15% of total operational expenses. A rolling mill might seem economically viable initially, but expensive upkeep can reduce profit margins. After all, equipment performance and reliability often vary across different models. Choose wisely, as even minor mistakes can lead to significant setbacks.

Top Tips for Choosing the Right Rolling Mill Machine

| Feature | Importance | Considerations |

|---|---|---|

| Material Type | High | Ensure the mill can handle the materials you plan to use. |

| Roll Size | Medium | Choose the size that meets your production needs. |

| Power Source | High | Consider whether electric, manual, or hydraulic is appropriate. |

| Adjustability | High | Select a mill that allows for easy adjustments to settings. |

| Durability | High | Look for sturdy construction that can withstand regular use. |

| Cost | Medium | Balance the initial investment with expected output value. |

Assessing Your Production Needs for a Rolling Mill

When selecting a rolling mill machine, assessing your production needs is crucial. Consider the materials you will work with. Are they soft, like aluminum, or harder, like steel? Each material requires different force and settings. Understanding this aspect can significantly impact your productivity and results.

Evaluate the volume of production you expect. Will you be producing small batches or large quantities? This affects the size and capacity of the rolling mill you need. A machine that is too small won't keep up with demand. Conversely, an oversized mill may waste resources and space.

Here are some tips to help you through the selection process. Identify your primary application. Will you focus on sheet metal, wire, or another product? Research the specifications and technical support needed. Consider the long-term costs too. Cheaper machines may require frequent repairs. Reflect on your workflow and how the machine will fit. This analysis helps avoid costly mistakes, ensuring that you choose wisely.

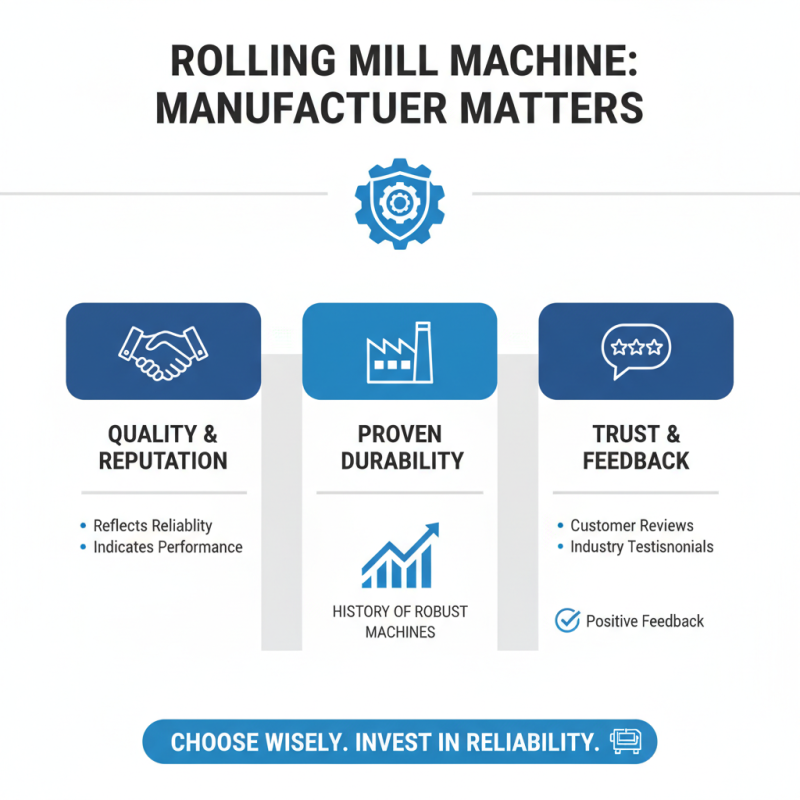

Evaluating the Quality and Reputation of Manufacturers

When choosing a rolling mill machine, the quality and reputation of the manufacturer are crucial. A solid reputation often reflects reliability and performance. Look for manufacturers with a history of producing durable machines. This can be assessed through customer reviews and industry testimonials. Positive feedback indicates a trustworthy company.

Consider visiting factories or workshops. Seeing the production process provides insight into the quality control measures in place. Ask about the materials used and the engineering techniques applied. Pay attention to how transparent the manufacturer is regarding their processes. Transparency often suggests confidence in their products.

Check for certifications that demonstrate quality standards. Certifications can show adherence to safety and durability benchmarks. A manufacturer with relevant certifications may be more dependable. However, remember that not all smaller companies will have these credentials, yet they could still produce excellent machines. Assessing multiple factors will help you make a more informed decision.

Budgeting for Your Rolling Mill: Costs and Financing Options

When budgeting for a rolling mill, consider several key factors. The initial cost of these machines can vary widely, ranging from $2,000 to over $50,000, depending on their features and capabilities. According to a recent industry report, businesses should allocate 10-15% of their total budget for maintenance and repairs. This often gets overlooked, yet it's crucial.

Financing options can ease the financial burden. Many companies opt for equipment leasing, which can reduce upfront costs significantly. A recent survey indicated that nearly 30% of small manufacturers use leasing instead of purchasing outright. However, remember that leasing often includes conditions that could restrict the usage of the equipment.

It's essential to remain flexible during the budgeting process. Unexpected costs may arise, such as installation or unexpected shipping fees. Regularly reviewing your budget and adjusting for these issues can make the process less stressful. A solid plan includes setting aside contingency funds. Ignoring this can lead to financial strain down the line.

Related Posts

-

What is a Roller Leveling Machine and How Does It Work?

-

Essential Tips for Choosing the Right Cold Rolling Machine Manufacturer

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

Why You Should Choose a Machine Slitter for Your Cutting Needs