Essential Tips for Choosing the Right Cold Rolling Machine Manufacturer

Choosing the right cold rolling machine manufacturer is a critical step for businesses in the metal processing industry. The performance and efficiency of cold rolling machines significantly impact the quality of the final products and the overall production process. With numerous manufacturers available in the market, selecting the most suitable one can be a daunting task. It requires a thorough understanding of various factors that contribute to the reliability and effectiveness of these machines.

When evaluating potential cold rolling machine manufacturers, it’s essential to consider their experience, reputation, and the technological advancements they integrate into their machinery. Manufacturers with a robust track record often provide insights into their products' durability and performance through positive user feedback and case studies. Additionally, the availability of after-sales support and customization options can also play a pivotal role in ensuring that the cold rolling solutions meet specific production needs.

By focusing on these crucial aspects, businesses can make informed decisions that lead to increased productivity and cost efficiency. This article aims to provide essential tips for evaluating cold rolling machine manufacturers, enabling stakeholders to choose the right partner for their operational success.

Understanding the Importance of Selecting the Right Manufacturer

Selecting the right manufacturer for cold rolling machines is crucial for optimizing production efficiency and ensuring consistent product quality. A study by the International Journal of Advanced Manufacturing Technology indicates that companies selecting high-quality manufacturers can achieve up to a 30% increase in production rates while also minimizing downtime. This demonstrates the significant impact that a reliable manufacturer can have not only on the operational workflow but also on the overall profitability of steel and metal processing companies.

Furthermore, the importance of understanding the manufacturing capabilities extends beyond mere production speed. A report from the Manufacturing Technology Association highlights that equipment sourced from reputable manufacturers often comes with better customer support and more advanced technology, leading to improved maintenance and less frequent breakdowns. Often, these manufacturers invest in research and development, enabling them to innovate and provide machines that are more energy-efficient and environmentally friendly. In a market where sustainability is increasingly prioritized, choosing a manufacturer that focuses on these aspects can bolster a company’s commitment to eco-friendly practices and compliance with global standards.

Key Factors to Consider in Cold Rolling Machine Manufacturing

When selecting a cold rolling machine manufacturer, several key factors play a crucial role in ensuring you make the right choice. First, consider the technology and innovation employed by the manufacturer. Advanced technology can lead to more efficient production processes and higher-quality outputs, which are essential in the highly competitive manufacturing landscape. Look for manufacturers who embrace modern automation, precision engineering, and robust research and development practices, as these can significantly enhance the longevity and reliability of the machines you invest in.

Another important factor is the level of customization offered. Every business has unique needs, and a one-size-fits-all approach may not yield the best results. A reputable manufacturer should provide tailored solutions to meet specific production requirements, which could range from machine size and configuration to software capabilities.

Additionally, assess their customer service and support infrastructure. A strong support system ensures that any issues can be promptly addressed, minimizing downtime and maintaining productivity. Investing time in evaluating these aspects will lead to a more informed decision, ultimately benefiting your operations in the long run.

Evaluating Manufacturer Experience and Industry Reputation

When selecting a cold rolling machine manufacturer, evaluating their experience and industry reputation is crucial. Manufacturers with a solid track record often possess the technical know-how and efficiency needed to produce high-quality machines. A well-established manufacturer not only understands the complexities involved in the cold rolling process but also adapts to the latest industry trends and technological advancements.

**Tip 1:** Research the manufacturer's history and portfolio to understand their experience in the cold rolling industry. Look for case studies or testimonials that highlight their past projects and client satisfaction. This insight can indicate their capability in delivering reliable machinery tailored to your specific needs.

**Tip 2:** Review industry reputation through forums, trade shows, and reviews from previous clients. Engaging with current or former customers can provide valuable feedback on the manufacturer’s performance, support services, and overall satisfaction. A strong reputation often signifies that the manufacturer stands behind their products and values customer relationships.

By focusing on these aspects, businesses can ensure they partner with a manufacturer that not only meets their technical requirements but also shares a commitment to quality and innovation in the cold rolling industry.

Essential Tips for Choosing the Right Cold Rolling Machine Manufacturer - Evaluating Manufacturer Experience and Industry Reputation

| Criteria | Description | Importance |

|---|---|---|

| Manufacturer Experience | Evaluate the number of years in the industry and expertise in cold rolling technologies. | High |

| Industry Reputation | Research reviews, testimonials, and industry awards to gauge reputation. | High |

| Product Quality | Assess the quality of machines and look for certifications such as ISO. | High |

| Customer Service | Check the availability of support and service for machine maintenance and issues. | Medium |

| Customization Options | Look into the ability to customize machines for specific needs. | Medium |

| Pricing | Understand the cost structures and compare them across manufacturers. | Medium |

| After-Sales Support | Consider the availability of training, spare parts, and repair services post-purchase. | High |

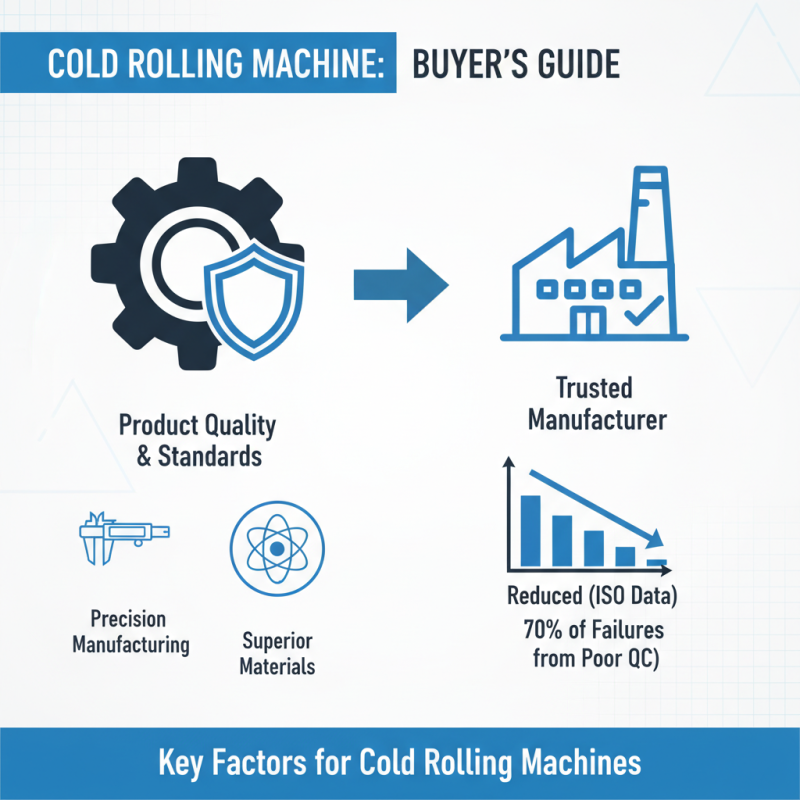

Assessing Product Quality and Compliance Standards

When selecting a cold rolling machine manufacturer, it is crucial to evaluate the product quality and compliance with industry standards. The performance and longevity of cold rolling machines significantly depend on the materials used and the precision in their manufacturing processes. For instance, according to the International Organization for Standardization (ISO), a significant percentage of machinery failures can be traced back to poor quality control in production, which underscores the importance of choosing a manufacturer that adheres to recognized quality standards.

Moreover, compliance with safety and environmental regulations is an essential factor. The global machinery market is increasingly influenced by compliance standards such as CE marking in Europe and ANSI/NBIMS in the United States. Research from Market Research Future indicates that the cold rolling machine market is projected to grow steadily, driven by demand in automotive, aerospace, and electronics industries. Manufacturers that are certified according to these standards not only ensure the safety of their products but also enhance their competitiveness in the market. Ensuring that your chosen manufacturer demonstrates a commitment to high-quality materials, strict compliance with industry standards, and a transparent quality assurance process can lead to better operational efficiency and reduced downtime in your production line.

Exploring Customer Support and After-Sales Service Options

When selecting a cold rolling machine manufacturer, the importance of robust customer support and after-sales service cannot be overstated. A manufacturer that prioritizes customer support demonstrates commitment not only to the initial sale but also to ensuring the longevity and efficiency of their equipment. Prospective buyers should seek companies that offer direct access to knowledgeable support staff who can assist with inquiries ranging from installation to operational troubleshooting. This ongoing relationship can significantly reduce downtime and improve overall productivity in the manufacturing process.

Moreover, after-sales service options are critical in different ways. Comprehensive service packages should include regular maintenance checks, availability of replacement parts, and options for upgrades as technology advances. A manufacturer that provides a clear service timeline and efficient response protocols can give operators confidence that they will not be left to navigate issues alone. Additionally, an understanding of warranty terms and repair policies is crucial; it helps assess the long-term value of the investment. Therefore, evaluating a manufacturer's customer service reputation and after-sales commitments is essential to making an informed decision.

Essential Tips for Choosing the Right Cold Rolling Machine Manufacturer

This chart illustrates the importance of various customer support and after-sales service options when selecting a cold rolling machine manufacturer. The data represents the percentage importance rated by potential customers based on their experiences and expectations.

Related Posts

-

Top 10 HR Slitting Machines for Precision and Efficiency in 2023

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs