Top 10 Tips for Choosing the Best Roller Mill Machine for Your Needs

Choosing the right roller mill machine can greatly impact your production efficiency. With numerous options available, it’s essential to consider your specific needs. A quality roller mill can enhance grain processing and feed production.

Think about the material you’ll be working with. The right roller mill machine should handle various grains effectively. Size and capacity also matter. A larger machine may meet high demand but might not fit in your workspace. Always measure your area before deciding.

While researching, some machines may look appealing but lack in performance. Read reviews and user experiences to avoid costly mistakes. Buying a roller mill machine is an investment. You want reliability and durability. Reflect on your long-term goals to guide your choice.

Understanding the Basics of Roller Mill Machines and Their Types

Roller mill machines are integral in various industries like agriculture and food processing. They crush or grind materials efficiently. Understanding their types helps you choose the right one for your needs. There are two main types: corrugated and smooth roller mills.

Corrugated rollers are great for breaking down hard materials. They create a rough texture in the final product. Smooth rollers, on the other hand, are ideal for fine grinding. They offer a smoother finish, perfect for specific applications.

Capacity is another key factor. Larger machines often handle more material. However, they can be pricier and consume more energy. Consider your production needs carefully. You might find that a smaller model could serve your purposes better.

Maintenance is something too often overlooked. Regular checks can prevent bigger issues later. A well-maintained mill will ensure consistent output. Forgetting this can lead to unexpected downtimes, impacting productivity. Take time to reflect on your specific requirements. Not every mill will fit every situation.

Key Factors to Consider When Assessing Roller Mill Specifications

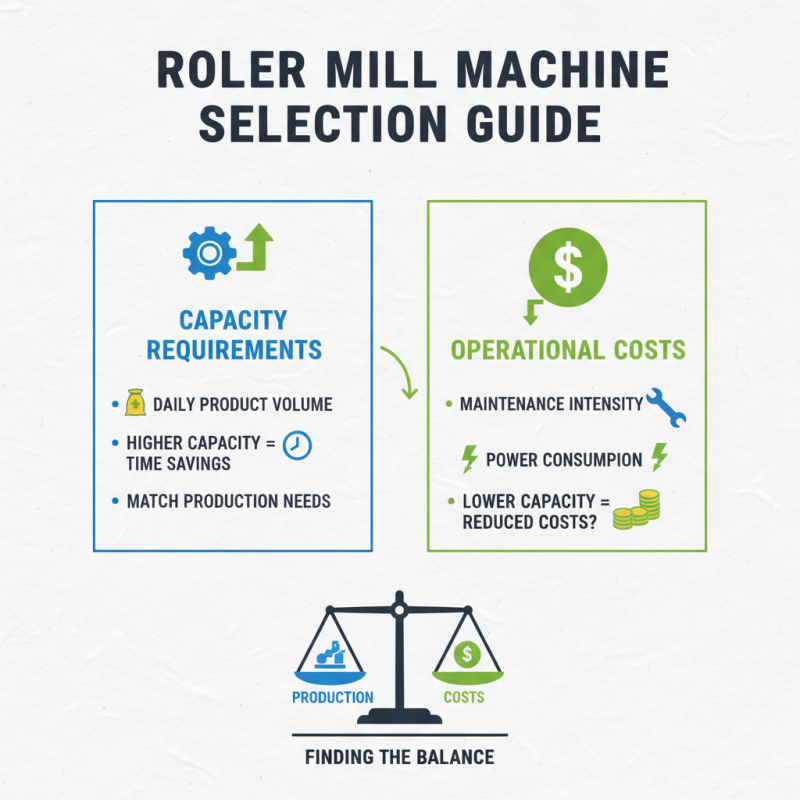

When selecting a roller mill machine, understanding the specifications is crucial. Begin by evaluating the capacity requirements. Consider how much product you need to process daily. A machine with a higher capacity can save time but may require more maintenance. Balancing production needs with operational costs is essential.

Next, examine the roller diameter and length. These dimensions affect the efficiency of the grinding process. Larger rollers can accommodate thicker materials. However, they may also increase energy consumption, which can be a long-term cost concern. It’s important to assess the trade-offs between efficiency and energy use.

Another key factor is the adjustable settings. Some machines offer fine-tuning options for various grain types. This adaptability can enhance performance but may complicate operation. Operators may struggle with settings, leading to inconsistent output. Reflecting on user experience can reveal hidden challenges. Always test a machine if possible before making a final decision.

Evaluating the Material Compatibility for Your Roller Mill Needs

When selecting a roller mill, evaluating material compatibility is crucial. Different materials require specific milling setups. For instance, grains and minerals have unique grinding needs. Understanding material properties helps optimize the milling process.

Pay attention to the hardness of your material. Hard materials could cause wear on the mill. This may lead to increased maintenance costs and reduce lifespan. On the flip side, softer materials might not require as robust a machine. You need to find a balance that fits your production goals.

Another consideration is moisture content. High moisture can create clumping, affecting output quality. If your material has high moisture, seek mills that handle this effectively. And remember, not all machines are perfect. Be open to adjustments after initial tests. These reflections will guide you in making the right choice over time.

Top 10 Tips for Choosing the Best Roller Mill Machine for Your Needs

| Tip Number | Tip Description | Material Compatibility | Key Features |

|---|---|---|---|

| 1 | Determine the Material Type | Grains, Ores | Adjustable gap settings |

| 2 | Assess the Processing Volume | High-volume processing | High-speed operation |

| 3 | Evaluate Power Requirements | Electric, Diesel | Energy-efficient motors |

| 4 | Check Maintenance Needs | Low-maintenance options | Easy access for repairs |

| 5 | Consider Size and Design | Compact vs. Industrial | Space-efficient layout |

| 6 | Look into Safety Features | Safety guards, shutoff systems | Emergency stop buttons |

| 7 | Research User Reviews | Real user experiences | Reliability information |

| 8 | Consult Industry Experts | Expert recommendations | Technical support availability |

| 9 | Compare Price vs. Features | Budget vs. capabilities | Value for money |

| 10 | Check Warranty and Support | Warranty terms | After-sales support |

The Importance of Brand Reputation and Customer Reviews in Selection

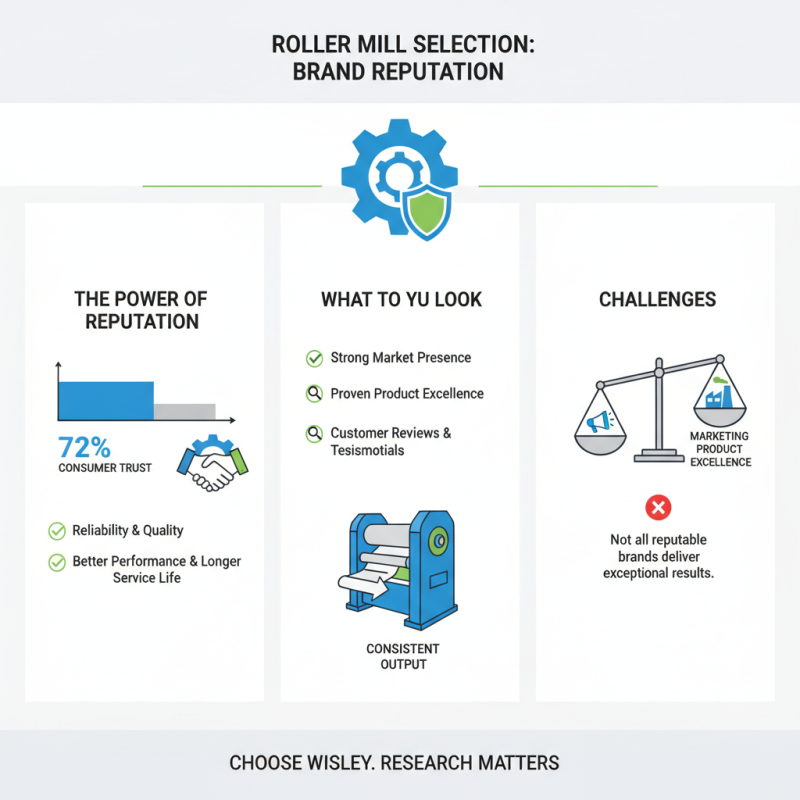

When selecting a roller mill machine, brand reputation plays a crucial role. A well-regarded brand often signifies reliability and quality. According to industry reports, about 72% of consumers trust brands with a strong presence in the market. A solid reputation can lead to better product performance and longer service life. However, not all reputable brands deliver exceptional results. Some may rely heavily on marketing instead of product excellence.

Customer reviews are equally important. They provide insights into real-world experiences. Research indicates that nearly 80% of potential buyers read reviews before making a purchase. A single negative review can impact the decision significantly. It’s critical to weigh positive and negative feedback. Some users might exaggerate their claims, while others might overlook serious flaws. This leads to the necessity for critical analysis.

As you gather information, look for trends in customer sentiment. Spot patterns in performance and durability. Sometimes, a product with mixed reviews may still meet your needs perfectly. Yet, relying solely on reviews can be misleading. The context behind each review often matters. A product that suits one operation may not be ideal for another. Approach feedback with an open mind and a critical eye.

Budgeting: Finding the Best Roller Mill within Your Price Range

When budgeting for a roller mill machine, it’s crucial to determine your specific needs. The price range for roller mills varies widely, often from $2,000 to over $10,000. Understanding what features you truly require can save you money. Reports indicate that businesses often overspend by 25% on equipment that exceeds their needs.

Consider both the initial cost and maintenance expenses. An efficient roller mill may have a higher upfront cost but can lead to better performance and lower long-term costs. A well-maintained mill can operate up to 20% more efficiently. Research shows that machinery with frequent mechanical issues results in costs that can exceed the original investment.

Evaluating total cost of ownership is essential. Look beyond the sticker price. Energy consumption should also be a key factor in your decision. Data suggests that energy-efficient mills can reduce costs by upwards of 15% annually. Think carefully about the features you value. Often, buyers are lured by advanced technology that isn't necessary for their operations.

Top 10 Roller Mill Machines Budget Comparison

Related Posts

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Top 10 HR Slitting Machines for Precision and Efficiency in 2023

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

Top Factors to Consider When Choosing a Roll Straightening Machine

-

Why You Need a Roll Straightener Machine for Efficient Metal Processing

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023