Top Slitter Machine Steel Features Benefits and Buying Guide

In the realm of metal processing, the slitter machine steel stands as a pivotal tool that enhances efficiency and precision. According to industry expert John Stevenson, a renowned consultant in steel processing technologies, "The selection of the right slitter machine steel can significantly influence both production speed and material quality." This underscores the importance of understanding the features and benefits offered by various slitter machine steels in order to make informed purchasing decisions.

When navigating the complexities of slitter machines, potential buyers must consider a multitude of factors, such as blade material, cut quality, and operational efficiency. The features inherent in high-quality slitter machine steels not only contribute to improved performance but also extend the operational lifespan of the equipment. As manufacturers continue to seek advancements in processing technologies, the demand for reliable and efficient slitter machine steel will only grow, making it essential to stay informed about the latest industry trends and innovations.

This guide aims to provide insights into the essential characteristics of slitter machine steels, highlighting their significant benefits and offering a comprehensive buying guide for industry professionals looking to optimize their production processes. Understanding these elements will empower businesses to select the best options suited to their specific needs, ultimately leading to enhanced productivity and material handling.

Overview of Slitter Machines: Definition and Purpose

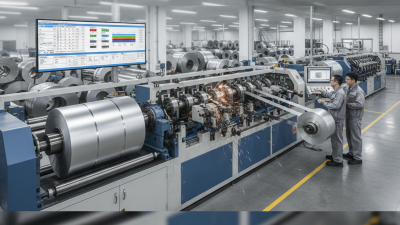

Slitter machines are essential tools in the manufacturing sector, primarily used for cutting large rolls of material, such as steel, into narrower strips or sheets. These machines function in various industries, including packaging, automotive, and construction, highlighting their versatility and importance. According to industry reports, the global slitter machine market is expected to grow at a CAGR of 5.6% from 2023 to 2028, driven by the increasing demand for precision cutting and efficient production processes.

The primary purpose of slitter machines is to enhance production efficiency by enabling high-speed cutting with minimal waste. With evolving technology, modern slitter machines offer features like fully automated processes, digital controls, and enhanced blade design, which significantly improve cutting accuracy and reduce downtime. For instance, advancements in blade material have led to extended life and reduced maintenance costs, which can be a game-changer for manufacturers aiming to maximize their operational efficiency.

Tip: When selecting a slitter machine, consider factors such as the type of materials to be cut and production volume, as these will influence the machine's speed and configuration. Additionally, ensuring proper maintenance routines can extend the lifespan of the slitter blades, preventing costly replacements and disruptions in production. Regular training for operators can also enhance the overall effectiveness of the slitting process, leading to better output quality.

Top Slitter Machine Features and Benefits

Key Features of Top Slitter Machines for Optimal Performance

When selecting a top slitter machine, understanding key features that contribute to optimal performance is crucial for manufacturers looking to enhance their production efficiency. One of the primary features to consider is the machine's cutting precision. High-precision slitter machines can achieve tolerances as tight as ±0.1 mm, enabling manufacturers in industries such as automotive and aerospace to meet stringent quality standards.

According to a recent industry report by MarketsandMarkets, the demand for precision slitting technology in these sectors is projected to grow by over 7% annually, highlighting the necessity for advanced machinery in competitive markets.

Another critical aspect is the machine's speed and productivity capabilities. Many top slitter machines are engineered to operate at speeds exceeding 300 meters per minute, reducing downtime and increasing output. Coupled with automated loading and unloading systems, these machines facilitate smoother operation and greater throughput. A survey conducted by the Fabricators and Manufacturers Association revealed that companies utilizing high-speed slitting machines have reported up to 30% increases in overall efficiency. This reflects the importance of investing in advanced technology that not only meets current production demands but also helps adapt to future industry trends.

Additionally, the versatility of slitter machines is essential for accommodating various materials, including stainless steel, aluminum, and composite materials. The ability of a slitter machine to handle different substrates can significantly enhance operational flexibility, allowing manufacturers to switch between materials without major reconfigurations. This adaptability is increasingly vital, as the global slitting industry anticipates a shift towards more diverse material usage, driven by innovations in product design and manufacturing processes.

Benefits of Using Slitter Machines in Steel Processing

Slitter machines play a critical role in steel processing, transforming large coils of steel into narrower strips for a variety of applications. One of the primary benefits of using slitter machines is their ability to enhance efficiency in production. By automating the cutting process, these machines significantly reduce labor costs and minimize the risk of human error, ensuring that steel strips are cut precisely to desired widths. This not only speeds up the overall processing time but also increases yield by reducing scrap.

Another advantage of slitter machines is their versatility. They can handle various types of steel, including stainless, carbon, and coated materials, allowing manufacturers to diversify their product offerings. Additionally, modern slitter machines come with advanced features, such as adjustable tension settings and innovative controls, which facilitate easier operation and maintenance. This flexibility ensures that manufacturers can respond quickly to changing market demands.

**Tips:** When selecting a slitter machine, consider the volume of work you expect to handle and choose a machine that offers scalability. Additionally, look for models equipped with user-friendly controls, as this can greatly reduce training time for operators. Regular maintenance is crucial for prolonging the lifespan of the machine, so establish a routine cleaning and inspection schedule to keep it in optimal condition.

Top Slitter Machine Steel Features Benefits and Buying Guide - Benefits of Using Slitter Machines in Steel Processing

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Precision Cutting | Ability to cut steel with high accuracy. | Reduces waste and ensures uniformity in parts. | Requires skilled operators to maintain precision. |

| Speed | Fast operation speeds for high-volume production. | Increases production capacity and efficiency. | May require additional investment in technology. |

| Versatility | Can handle various thicknesses and materials. | Applicable for diverse products and industries. | May need adjustments for different material types. |

| Cost Efficiency | Long-term savings on raw material and labor. | Improves profit margins through reduced costs. | Initial setup may require significant investment. |

| Automation | Integration with automated processes and systems. | Enhances productivity and consistency in operations. | Training needed for staff on automated systems. |

Considerations When Buying a Slitter Machine: What to Look For

When considering the purchase of a slitter machine, there are several crucial factors to keep in mind to ensure you make an informed decision. First, assess the material types you will be processing. Different slitter machines are designed for specific materials, such as steel, aluminum, or other metals, and this can influence cutting precision and efficiency. Additionally, consider the thickness and width ranges your operations will require, as these specifications dictate the capabilities of the machine and its adaptability to various applications.

Another important aspect to evaluate is the machine's cutting technology. Various slitter designs feature different blade configurations, which can affect the quality of the cut and the overall performance of the machine. Look for features such as adjustable blade positions and the ability to easily replace blades, which can enhance flexibility and maintenance ease. Furthermore, it's essential to think about the machine's speed and production rate, as this will have a direct impact on your productivity and operational efficiency. Investing time in understanding these considerations will help you choose a slitter machine that best fits your business needs and contributes to a streamlined manufacturing process.

Maintenance Tips for Maximizing the Lifespan of Slitter Machines

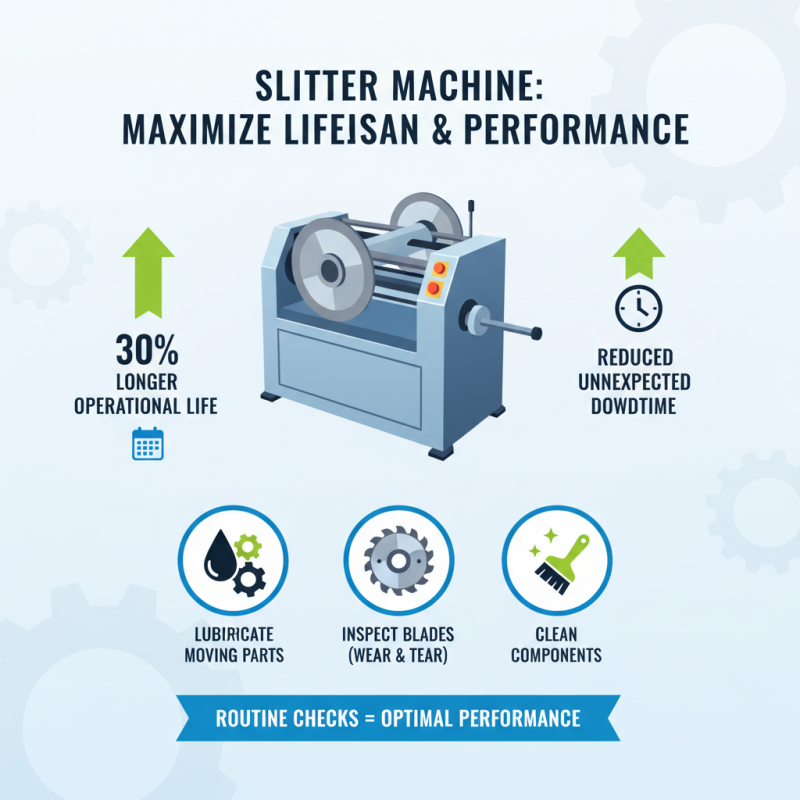

Maintaining a slitter machine is crucial for maximizing its operational lifespan and ensuring optimal performance. Regular maintenance practices can significantly reduce the risk of unexpected downtimes and extend the machine's usability. According to industry reports, well-maintained slitter machines can last up to 30% longer than those that do not receive regular upkeep. Routine checks, including the lubrication of moving parts, inspection of blades for wear and tear, and cleaning of various components, are essential steps in this maintenance regimen.

Additionally, the environment in which a slitter machine operates can have a major impact on its longevity. Contaminants such as dust and debris can lead to premature wear, while proper ventilation can prevent overheating. Research indicates that maintaining optimal operating conditions can improve efficiency by up to 50%, making such environment considerations just as critical as the mechanical upkeep. Operators should also keep a close eye on the machine’s performance metrics and schedule predictive maintenance based on usage patterns, which further helps in identifying potential issues before they escalate into costly repairs.

Related Posts

-

How to Choose the Right Coil Cutting Machine for Your Business Needs

-

Why You Need a Roll Straightener Machine for Efficient Metal Processing

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

Top 10 Benefits of Using Stainless Steel Slitting Machines for Your Business

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs