What is a Sheet Metal Slitting Machine and How Does It Work?

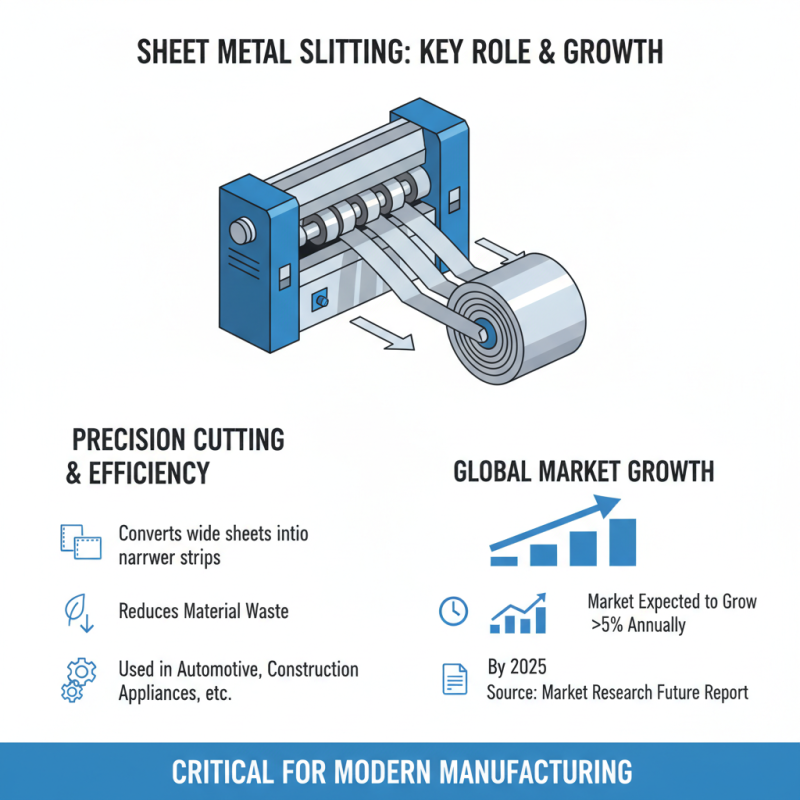

The sheet metal slitting machine plays a vital role in the manufacturing industry. It is essential for processing large coils of metal into narrower strips. According to a market research report by Grand View Research, the global sheet metal fabrication market is projected to reach $303 billion by 2028. This shows the growing demand for efficient and precise metal processing methods.

These machines operate by using sharp blades to cut through metal sheets. The slitting process is crucial for industries such as automotive, construction, and electronics. However, users sometimes struggle with blade alignment and maintenance. These challenges can affect production efficiency and product quality. Investing in training and support is necessary to optimize machine performance.

Moreover, the rise in automation presents both opportunities and challenges. While it enhances productivity, operators must adapt to new technologies. This shift requires ongoing education and adjustment to ensure success. The sheet metal slitting machine, despite its complexities, remains a fundamental asset in the manufacturing landscape.

What is a Sheet Metal Slitting Machine?

A sheet metal slitting machine is essential in metal processing. It specializes in cutting large coils of sheet metal into narrower strips. This process is vital for many industries, including automotive and manufacturing. According to industry reports, the sheet metal fabrication market is projected to grow significantly, reaching over $230 billion by 2026.

The operation of a slitting machine involves feeding the metal coil through sharp blades. These blades slice through the metal with precision, resulting in clean edges. Proper alignment is crucial. Misalignment can lead to waste and increased costs. Reports indicate that even a minor error can increase production costs by nearly 10%. Efficiency in this process is vital, as production rates can vary.

However, there are challenges. Operators must regularly check blade sharpness and machine alignment. Neglecting maintenance can lead to inconsistent cuts and downtime. One study highlighted that nearly 15% of machinery breakdowns occur due to poor upkeep. Investing in training for operators can improve productivity and reduce errors, but many companies overlook this aspect. The focus should also be on investing in technology to enhance precision, making the slitting process smoother.

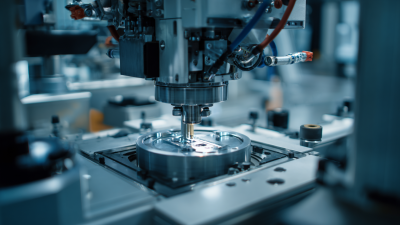

Key Components of a Sheet Metal Slitting Machine

A sheet metal slitting machine is essential for processing metal sheets. It accurately cuts large coils into narrower strips. This process is efficient and minimizes waste. The key components are crucial for its operation.

First, we have the unwind stand. It holds the metal coil securely. It ensures a smooth feed into the machine. If not properly aligned, it can cause jams. Next is the slitting station, where the actual cutting happens. It features sharp blades that slice through the metal. The quality of these blades is vital. Dull blades can lead to uneven cuts.

Additionally, there is the tensioning device. This component maintains the right tension on the metal during cutting. Too much tension can warp the metal; too little can create inconsistent cuts. Lastly, the rewinding unit collects the finished strips. If it doesn't function correctly, it can ruin the entire batch. Each of these components plays a significant role, and any flaw can impact the output quality.

Operating Principles of a Sheet Metal Slitting Machine

A sheet metal slitting machine is a vital tool in manufacturing. It’s designed to cut metal sheets into narrower strips. This process is crucial for various applications, including automotive and construction industries. Understanding its operating principles helps maximize efficiency.

The machine operates using a series of rotating blades. These blades are aligned in a specific manner to create precise cuts. As the metal sheet passes through, the blades shear the material. This action demands careful calibration to ensure uniform output. An improperly set machine can lead to irregular strips, wasting resources.

Additionally, safety is a paramount consideration. Operators must be aware of the moving parts and potential hazards. Regular maintenance checks are essential to prevent malfunctions. If the machine is not properly maintained, it could lead to inaccurate cuts. Operators should be trained to recognize signs of wear and tear on blades. This awareness can prevent costly downtime and increase overall productivity.

Different Types of Sheet Metal Slitting Machines

Sheet metal slitting machines come in various types, each serving different purposes in the metal fabrication industry. The standard slitting machine uses rotary blades to cut large sheets into narrower rolls or strips. This type is often found in large manufacturing facilities. It allows for precise cuts and ensures uniformity. Some machines are equipped with multiple blades, enabling multiple slits in one pass. This feature can boost productivity significantly. However, it requires regular maintenance to ensure consistent performance.

Another popular type is the shear slitting machine. This machine uses a vertical blade, creating a shearing action that cuts through the metal. It can handle thicker sheets and offers flexibility in cutting shapes. Still, the sheer force can sometimes result in rough edges. Manufacturers need to consider this when designing their processes. Another variant is the rotary shear machine, which uses rotating knives. It is great for high-speed operations, but alignment is crucial. Misalignment can lead to waste, so regular calibration is essential. Each machine has its benefits, yet manufacturers must reflect on their specific needs to choose the right type.

Applications and Benefits of Sheet Metal Slitting Machines

Sheet metal slitting machines play a vital role in various manufacturing sectors. They cut wide sheets into narrower strips with precision. This method is efficient and reduces material waste. According to a recent report from Market Research Future, the global sheet metal processing market is expected to grow by over 5% annually by 2025.

Industries benefit significantly from these machines. Automotive manufacturers use them for creating components like brackets and panels. In construction, they provide materials for structural framework and roofing. The flexibility of slitting machines allows for customization in thickness and width, catering to specific project requirements. However, some challenges exist. Over time, blades may dull, affecting cut quality. Regular maintenance is crucial to ensure optimal performance and minimize downtimes.

Energy efficiency is another consideration. Advanced models integrate technology to reduce power consumption. A survey from the Energy Information Administration reveals that industrial facilities could save up to 30% on energy costs by using modern equipment. This potential for savings stems from improved operations and reduced waste in the production process.

Related Posts

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

What is a Roller Leveling Machine and How Does It Work?

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

What is a Metal Processing Machine and How Does It Work?

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions