What is a Roller Leveling Machine and How Does It Work?

The roller leveling machine plays a crucial role in the metal fabrication industry, specifically in the processing of sheet and plate materials. As manufacturers increasingly strive for precision in their operations, the demand for advanced leveling technologies has surged. According to a report by Grand View Research, the global market for metal surface treatment is projected to reach USD 8 billion by 2027, with a significant portion driven by the need for enhanced flatness in metal products.

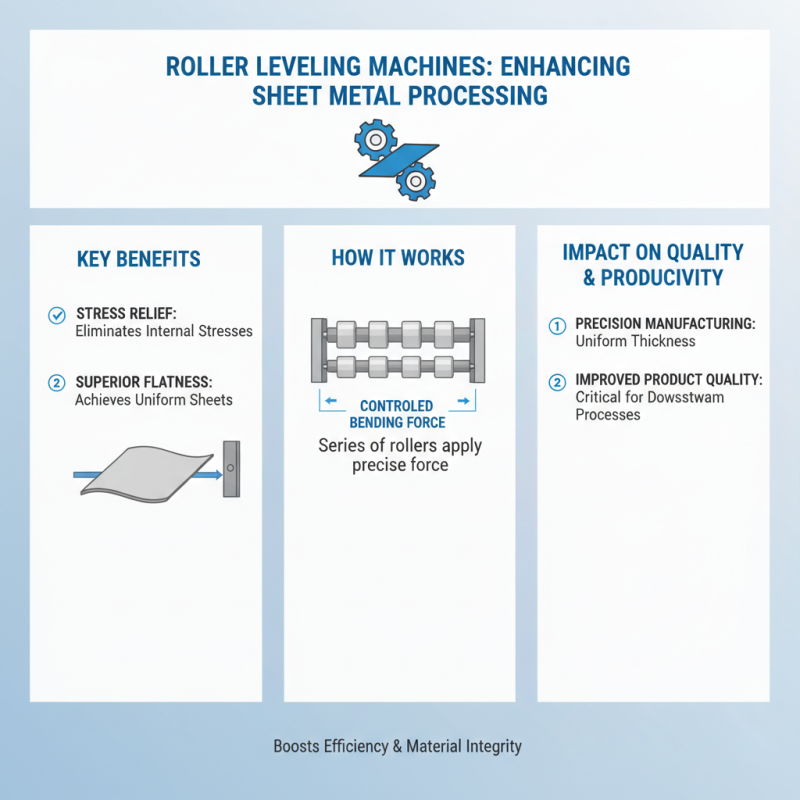

A roller leveling machine employs a series of rollers to flatten metal sheets by eliminating residual stresses and ensuring uniform thickness. This process not only improves the aesthetic quality of the final product but also enhances its mechanical properties, mitigating issues such as warping during subsequent manufacturing processes. As metal production continues to evolve, industry experts emphasize the importance of investing in advanced leveling machines to increase productivity and maintain competitive advantage, thereby solidifying the roller leveling machine as an indispensable tool for modern metalworking operations.

Understanding the operational mechanisms and benefits of a roller leveling machine is essential for industry professionals aiming to optimize their workflow and product quality. With technological advancements and growing market demands, the roller leveling machine stands at the forefront of enhancing the efficiency and reliability of metal processing.

What is a Roller Leveling Machine?

A roller leveling machine is an essential piece of equipment in metal processing that enhances the quality of various sheet metal products. This machine operates by passing metal sheets through a series of rollers, which work to flatten them. The levels of precision and efficiency achieved by roller leveling machines make them indispensable in industries such as automotive manufacturing, construction, and metal fabrication. By correcting imperfections such as warping or bending, these machines ensure that metal sheets achieve a flat and uniform profile, which is critical for further processing.

When using a roller leveling machine, it's important to keep a few tips in mind. Ensure that the material being leveled is compatible with the machine's specifications to avoid damage. Regular maintenance and calibration of the rollers can significantly extend the machine's lifespan and produce consistent results. Additionally, monitoring the thickness and condition of the sheets during the leveling process can help maintain high-quality standards.

Another key tip is to operate the machine at the correct speed. Adjusting the feed rate can drastically influence the outcome, so it’s vital to find a balance that prevents distortion while achieving the desired flatness. Adequate operator training is also crucial to maximize the machine's capabilities and ensure safety during operation.

What is a Roller Leveling Machine and How Does It Work?

| Feature | Description | Benefits |

|---|---|---|

| Functionality | Used to level metal sheets and strips by passing them through a set of rollers. | Improves flatness and reduces residual stress in materials. |

| Components | Typically consists of rollers, a frame, and a feeding mechanism. | Enhances durability and efficiency of the leveling process. |

| Applications | Used in industries such as automotive, aerospace, and manufacturing. | Ensures quality and precision in metal components. |

| Operating Principle | Material is fed through rollers that apply controlled pressure. | Produces a consistently flat product with minimized distortion. |

| Advantages | Increases production efficiency and product quality. | Reduces costs associated with rework and scrap materials. |

Key Components of a Roller Leveling Machine

Roller leveling machines are essential in the metal processing industry, serving to flatten steel sheets and other materials effectively. One of the crucial components of these machines is the roller system itself, which consists of multiple rollers arranged in a specific configuration. These rollers rotate in a synchronized manner, applying controlled pressure to the material as it passes through. The design of the rollers allows for precise adjustments to accommodate different thicknesses and types of materials, ensuring a consistent and smooth finish.

Another key component is the feeding mechanism, which guides the material into the machine at the correct speed and alignment. This system often includes a series of conveyor belts and sensors that monitor the status of the workpiece, facilitating a seamless process. Additionally, the machine may incorporate hydraulic or pneumatic systems that assist in adjusting the roller gaps, allowing operators to fine-tune the machinery for optimal performance. Together, these components work in synergy to enhance the efficiency and effectiveness of the roller leveling process, making it a vital part of metal fabrication.

The Working Principle of Roller Leveling Machines

Roller leveling machines play a crucial role in modern manufacturing processes by ensuring the flatness and consistency of materials such as metal sheets. The working principle of roller leveling machines involves a series of rollers that apply precise pressure to deform and straighten the material. The setup typically includes a series of adjustable rollers arranged in a staggered pattern that progressively work the material. As the sheet passes through these rollers, it undergoes a controlled bending process, which effectively removes internal stresses and inconsistencies, resulting in a flatter product. According to the latest industry reports, approximately 30% of metal fabrication companies rely on roller leveling machines to enhance their product quality and operational efficiency.

The effectiveness of roller leveling machines is largely determined by several factors, including roller diameter, material thickness, and the configuration of the roller arrangement. Research from industry experts suggests that the optimal roller spacing and tension settings can significantly enhance the leveling process, allowing for better control of the final product's flatness. Additionally, advancements in technology have led to the integration of automation features in modern roller leveling machines. By incorporating sensors and real-time monitoring, manufacturers can achieve higher precision levels and improve overall production rates, which is essential for meeting the growing demand within sectors such as automotive and construction. Reports suggest that companies utilizing advanced roller leveling technologies can experience productivity gains of up to 25%.

Roller Leveling Machine Performance Data

This chart displays the average thickness deviation of metal sheets processed by roller leveling machines over different material types.

Applications of Roller Leveling Machines in Industry

Roller leveling machines play a crucial role in various industrial applications by providing precise leveling of metal sheets and other flat materials. One of the primary uses of these machines is in the manufacturing sector, where consistent flatness is essential for further processing. For instance, in the automotive industry, roller leveling machines are used to prepare steel sheets that will be shaped into vehicle bodies, ensuring that they meet stringent dimensional tolerances. The process enhances the material's integrity and reduces the likelihood of defects during subsequent fabrication stages.

In addition to the automotive sector, roller leveling machines are commonly employed in construction and appliance manufacturing. In construction, these machines help in producing flat panel materials that are essential for structural applications, ensuring that components fit together seamlessly. Similarly, in appliance manufacturing, leveled sheets are crucial for creating housings and components that require a smooth finish and proper alignment. The versatility of roller leveling machines thus makes them indispensable across various industries, capitalizing on their ability to process a range of materials while maintaining high accuracy in leveling.

Benefits of Using Roller Leveling Machines for Sheet Metal Processing

Roller leveling machines play a crucial role in the processing of sheet metal, providing numerous benefits that enhance both productivity and product quality. One of the primary advantages of using these machines is their ability to eliminate internal stresses and flatten sheet materials efficiently. By employing a series of rollers that apply a controlled bending force, roller leveling machines can produce highly uniform sheets with minimal thickness variation. This precision is vital in industries where the integrity of the metal sheets is critical for subsequent manufacturing processes.

Another significant benefit of roller leveling machines is their capacity for handling a wide range of materials and thicknesses. This versatility allows manufacturers to work with different types of metals, including steel, aluminum, and copper, without needing separate leveling solutions for each material. Additionally, the high throughput capabilities of these machines enable quicker processing times, helping companies meet tight deadlines while maintaining high standards of quality. As a result, businesses that utilize roller leveling machines can improve their operational efficiency, reduce waste, and enhance the overall quality of their products.

Related Posts

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine