Why You Need a Roll Straightener Machine for Efficient Metal Processing

In the world of metal processing, efficiency and precision are paramount. The demand for high-quality metal products has surged, with the global metal processing market projected to reach $1.2 trillion by 2024, according to recent industry reports. As businesses strive to meet this growing demand, the role of advanced machinery becomes increasingly critical. One such machine that plays a vital role in ensuring optimal product quality and operational efficiency is the roll straightener machine.

A roll straightener machine is designed to correct imperfections in metal products, such as bends and twists, which can arise during the manufacturing process. According to research by the Metal Forming Industry Association, up to 30% of production time can be lost due to material handling issues and inefficiencies, highlighting the need for reliable equipment that enhances workflow. The implementation of a roll straightener machine not only minimizes waste but also boosts the overall productivity of metal processing operations. By incorporating this technology, manufacturers can achieve tighter tolerances and decrease rework costs, ultimately leading to increased profitability and competitive advantage in the market.

In an industry where precision is non-negotiable, investing in a roll straightener machine is not just beneficial but essential for companies looking to streamline their production processes. As the metal processing sector continues to evolve, embracing innovative solutions will be key to sustaining growth and meeting customer expectations.

Benefits of Using a Roll Straightener Machine in Metal Processing

The utilization of a roll straightener machine in metal processing offers several significant benefits that enhance operational efficiency and product quality. According to a recent industry report, the straightening process can reduce material waste by up to 15%, making it a vital component in manufacturing processes. This reduction not only conserves resources but also decreases costs associated with scrap metal, allowing companies to allocate those savings toward other areas of production.

Moreover, roll straighteners play a crucial role in improving the mechanical properties of metals. The process of straightening helps eliminate internal stresses and irregularities in the material, resulting in a more uniform product. Enhanced uniformity can lead to better performance of the final components, especially in industries such as automotive and aerospace, where precision is paramount. An analysis from the International Journal of Metal Processing indicates that utilizing advanced straightening technologies can increase the lifespan of metal products by as much as 20%, highlighting the long-term benefits of integrating such machinery into production lines.

Furthermore, automation in roll straightening can significantly boost productivity. Modern machines are designed to handle higher volumes with reduced human intervention, allowing for streamlined operations. Reports from metalworking associations suggest that automated straightening systems can increase throughput by over 30%, enabling manufacturers to meet growing market demands without compromising on quality. Overall, the implementation of roll straightener machines not only optimizes manufacturing processes but also strengthens the competitive edge of metal processing firms.

How Roll Straighteners Improve Material Quality and Consistency

Roll straighteners play a crucial role in enhancing the quality and consistency of metal materials during processing. These machines are designed to reduce or eliminate the distortions that can occur in metal sheets and bars, resulting in more uniform products. According to the **International Journal of Advanced Manufacturing Technology**, straightening can lead to a 30% increase in the precision of materials, significantly impacting downstream processes. This improvement not only ensures that dimensions meet specifications but also enhances surface quality, thereby reducing the risks of defects during further machining or forming.

Tips for optimizing the use of roll straighteners include regularly maintaining the machine to ensure its alignment is accurate, as improper setup can lead to uneven straightening. Additionally, monitoring the materials for temperature and hardness before processing can help assess whether pre-straightening treatments are necessary, leading to better adjustments during the rolling process. Furthermore, incorporating data analytics can help track the efficiencies of the straightening process, allowing operators to make data-driven decisions that enhance overall productivity.

In terms of material consistency, using a roll straightener can minimize variations in mechanical properties across a batch of steel or aluminum. A report from the **Metal Processing Journal** indicates that operations utilizing roll straighteners reported a 40% reduction in variability in yield strength and ductility, thereby improving the reliability of the end product. Such consistency not only boosts the quality of individual items but also greatly enhances brand reputation and customer satisfaction.

Key Features to Look for in a Roll Straightener Machine

When considering the acquisition of a roll straightener machine, it is essential to focus on key features that enhance efficiency and effectiveness in metal processing. One of the most critical aspects is the machine's ability to handle various material types and thicknesses. According to industry reports, incorporating a roll straightener that can process up to 90% of common materials, including steel and aluminum, significantly optimizes production processes. This capability not only improves versatility but also reduces downtime associated with material changes.

Another vital feature to consider is the machine's speed and precision. High-quality roll straighteners can provide straightening speeds of 20-60 meters per minute without compromising the accuracy of the output. Precision in straightening is essential, as even minor deviations can lead to increased waste and rework costs. Investing in machines equipped with advanced technology, such as electronic control systems, can offer enhanced accuracy and intelligent monitoring, resulting in more efficient operations.

Tips: Choose a roll straightener that offers easy adjustments and calibration settings. This will ensure quick responses to varying production needs. Additionally, opt for a machine with a user-friendly interface for better operational efficiency. Finally, consider the machine's maintenance requirements; a design that allows for easy access to components can save valuable time and resources over the machine's lifespan.

Why You Need a Roll Straightener Machine for Efficient Metal Processing - Key Features to Look for in a Roll Straightener Machine

| Feature | Description | Importance |

|---|---|---|

| Precision Adjustment | Allows for fine-tuning of straightening processes to meet specific material requirements. | Essential for achieving desired tolerances and minimizing waste. |

| Speed Control | Enables adjustment of the feed rate to optimize processing time. | Increases efficiency and productivity in metal processing. |

| Durability | Constructed from high-quality materials to withstand heavy usage. | Reduces maintenance costs and enhances longevity of the equipment. |

| User-Friendly Interface | Easy-to-navigate controls for quick setup and operation. | Decreases training time for operators and reduces operational errors. |

| Multi-Functionality | Can handle a variety of materials and shapes. | Enhances versatility and utility of the machine in different applications. |

Applications of Roll Straighteners in Various Industries

Roll straightener machines play a crucial role in numerous industries where precise metal processing is essential. In the automotive sector, for instance, these machines are vital for straightening various metal components used in vehicle assembly. The high-speed production lines demand consistent material quality and precision, and roll straighteners ensure that the metal bars and rods are perfectly aligned, reducing the chances of defects in the final products. This precision leads to improved safety and functionality in vehicles, making roll straighteners indispensable in automotive manufacturing.

In the construction and structural steel industries, roll straighteners contribute significantly to the production of beams and reinforcement bars. These industries rely on straightened metal for structural integrity and strength. By utilizing roll straighteners, manufacturers can achieve the required dimensions and specifications, ensuring that the materials can withstand the demands of construction projects. This enhanced performance not only optimizes production but also minimizes waste, making it a cost-effective solution for manufacturers. The versatility of roll straighteners across various industries highlights their importance in achieving operational efficiency and superior product quality.

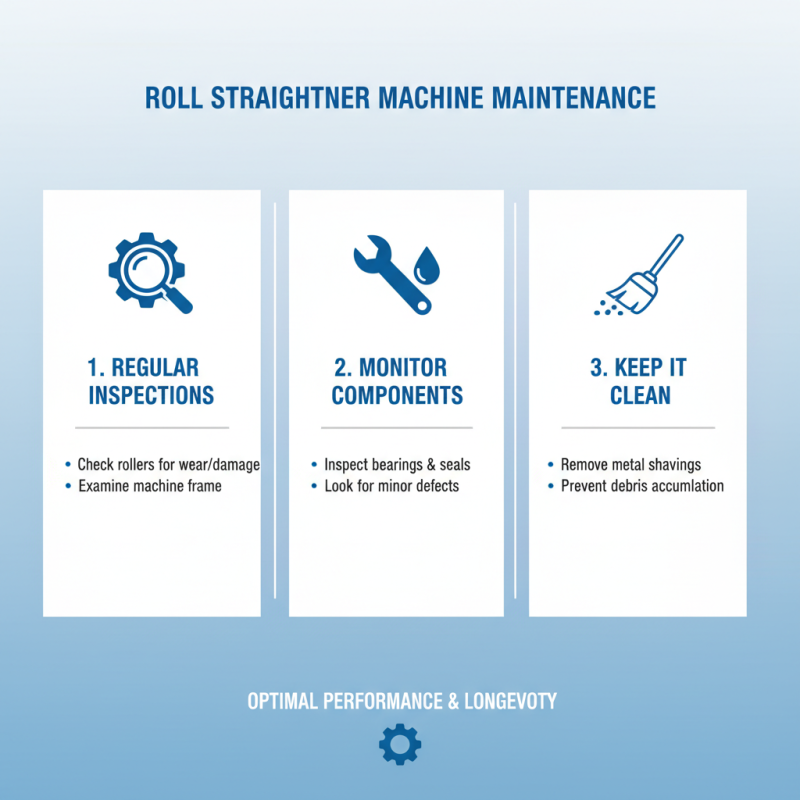

Maintenance Practices for Optimal Performance of Roll Straighteners

Proper maintenance of roll straightener machines is essential for ensuring optimal performance and longevity. Regular inspections should be conducted to check for any signs of wear or damage to the rollers and the machine's frame. Components such as bearings and seals should also be monitored closely, as even minor defects can lead to significant operational issues. Keeping the machine clean from metal shavings and debris is critical, as accumulated material can hinder its operation and cause premature wear.

Lubrication plays a vital role in the maintenance of roll straighteners. Using the recommended lubricants, ensure that all moving parts are adequately oiled to minimize friction and improve efficiency. Scheduled lubrication routines should be established to prevent any lapses. Additionally, operators should be trained in recognizing unusual sounds or vibrations, which can indicate underlying mechanical problems. Implementing a proactive maintenance schedule not only supports optimal performance but also enhances safety in the workplace, as machines in good condition are less likely to fail unexpectedly.

Related Posts

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

What is a Roller Leveling Machine and How Does It Work?

-

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

How to Choose the Right Coil Cutting Machine for Your Business Needs