2025 How to Optimize Your Production with KUKA Machines Efficiently

In the rapidly evolving landscape of manufacturing, optimizing production processes is essential for maintaining a competitive edge. As companies increasingly turn to automation, the role of KUKA machines has become paramount in achieving operational efficiency. Renowned industry expert Dr. Michael Peters, a leading figure in robotics and automation, once stated, "The future of manufacturing lies in smart technology, and KUKA machines are at the forefront of this transformative wave."

In this guide, we will explore the "Top 5" strategies for optimizing production with KUKA machines effectively. From streamlining workflow to leveraging advanced programming techniques, organizations can dramatically enhance their productivity and reduce costs. By harnessing the full potential of KUKA machines, manufacturers can not only meet the demands of today's market but also lay the groundwork for future advancements in smart manufacturing.

By understanding the intricate functionalities and capabilities of KUKA machines, businesses can adopt a holistic approach to automation that maximizes efficiency and minimizes downtime. Stay tuned as we delve deeper into actionable insights and best practices that can propel your manufacturing processes into a new era of productivity.

Key Features of KUKA Machines That Enhance Production Efficiency

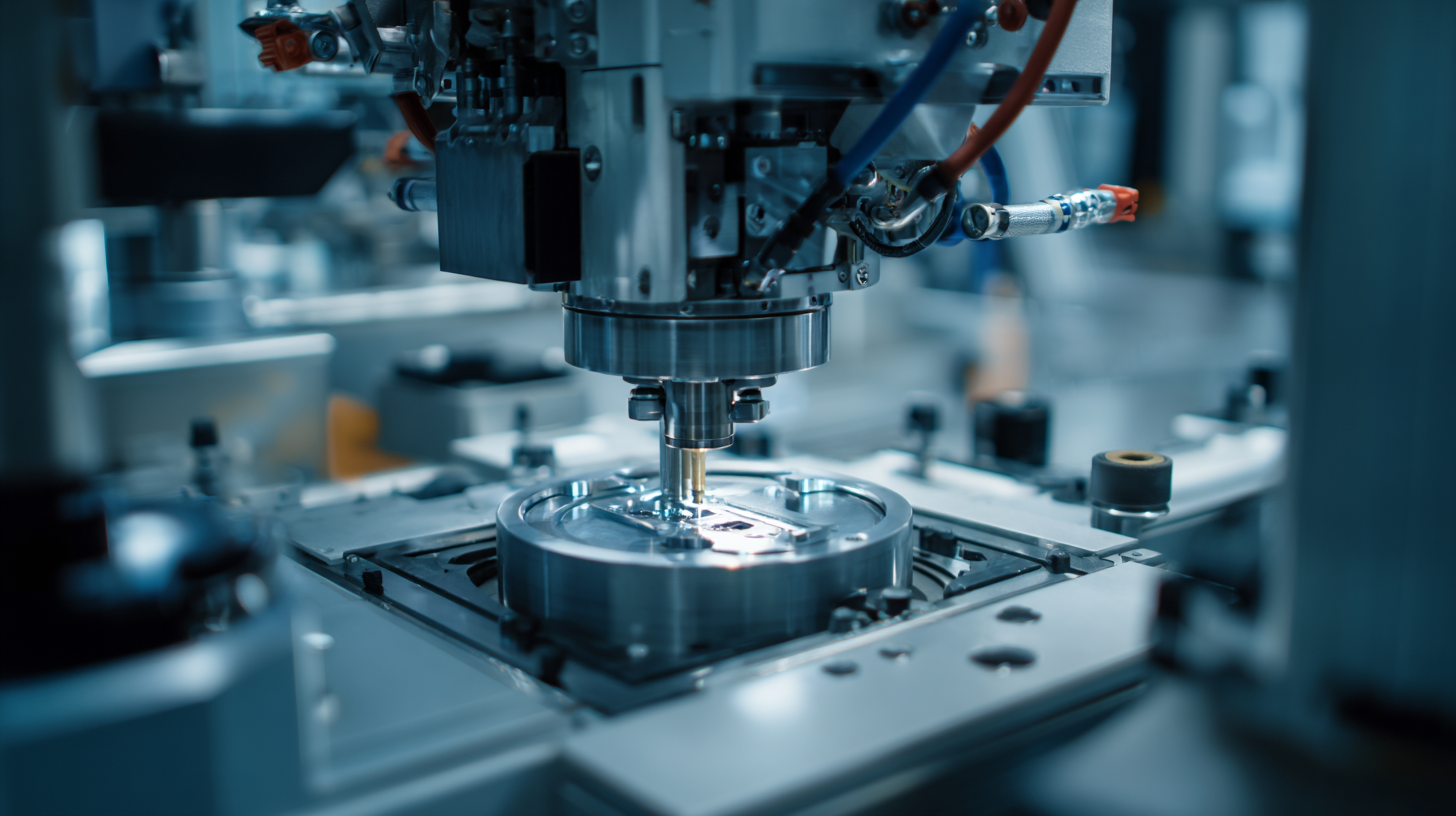

KUKA machines are designed to significantly enhance production efficiency through their cutting-edge features and innovative technology. One of the key attributes of KUKA machines is their flexibility, allowing users to easily adapt to varying production demands. With the ability to program multiple tasks, manufacturers can optimize their workflows, reduce downtime, and quickly switch between different product lines. This adaptability can lead to significant time and cost savings, making KUKA machines an indispensable asset in modern production environments.

Tip: Invest time in training your team on KUKA’s programming capabilities. A well-trained workforce can maximize the potential of these machines, ensuring they operate at peak capacity and contribute to overall productivity.

Another standout feature of KUKA machines is their precision. Equipped with advanced sensors and algorithms, these machines deliver consistent quality and minimize errors in production. This precision not only reduces waste but also enhances the reliability of product output, which is crucial in maintaining customer satisfaction. Additionally, the integration of IoT technology allows for real-time monitoring and predictive maintenance, further ensuring that production remains uninterrupted.

Tip: Regularly update the software and firmware of your KUKA machines. Keeping your equipment up to date can improve performance and introduce new features that enhance efficiency.

Integrating KUKA Machines into Existing Production Lines Seamlessly

Integrating KUKA machines into existing production lines can dramatically enhance operational efficiency. According to a recent report from the International Federation of Robotics, the global demand for industrial robots is projected to grow at a rate of 12% annually, underscoring the importance of seamless integration in production environments. By employing KUKA's advanced automation technology, companies can streamline workflows, reduce cycle times, and improve overall productivity without the need for significant line disruptions.

The key to successful integration lies in the adaptability of KUKA machines. These robots are designed to work collaboratively with existing equipment, allowing for a phased implementation that minimizes downtime. A study published by McKinsey & Company indicates that companies that integrate robotics into their production processes can see productivity increases of up to 30%. The versatility of KUKA systems makes it easier to tailor solutions that fit your unique production needs, whether it's in automotive, electronics, or food and beverage industries. This adaptability not only enhances operational efficiency but also facilitates a smoother transition for operators accustomed to traditional manufacturing methods.

Top Automation Techniques to Maximize Output with KUKA Equipment

In the quest to maximize output with KUKA equipment, implementing top automation techniques is essential for optimizing production. One key method is the integration of KUKA's collaborative robots (cobots), which can work alongside human operators to enhance efficiency. By automating repetitive tasks such as assembly, packaging, and quality inspection, manufacturers can significantly increase throughput while also improving workplace safety. Cobots are designed to be easily programmable, allowing for swift adjustments to production lines in response to changing demands.

Another effective technique is leveraging KUKA’s advanced simulation software, which allows for the planning and visualization of production processes before actual implementation. This proactive approach can identify potential bottlenecks and inefficiencies, enabling manufacturers to optimize workflow and resource allocation. Additionally, incorporating IoT (Internet of Things) functionality into KUKA machinery facilitates real-time monitoring and data analysis, providing insights that can drive continuous improvement in production practices. Through these automation strategies, businesses can ensure they are not only increasing output but also maintaining a high standard of quality and innovation in their operations.

Production Optimization with KUKA Machines in 2025

This chart demonstrates the monthly output of a production line using KUKA machines over four quarters in 2025. The data shows a steady increase in output, indicating effective optimization and the implementation of top automation techniques.

Best Practices for Maintenance and Management of KUKA Systems

Effective maintenance and management of KUKA systems are crucial for optimizing production processes. Regular maintenance schedules should be established for all KUKA machines to ensure their longevity and peak performance. This includes routine checks on mechanical components, software updates, and calibration to prevent unexpected downtimes. Implementing a preventive maintenance plan not only helps in identifying potential issues before they escalate but also reduces repair costs and prolongs equipment life.

In addition to maintenance, effective management of KUKA systems involves proper training for operators and technicians. Understanding the functionality and capabilities of KUKA machines empowers users to make informed decisions, thus enhancing overall productivity. It is also beneficial to utilize KUKA’s digital tools for monitoring system performance in real-time. These tools provide valuable insights into operational efficiencies, allowing for data-driven adjustments that can streamline workflows. By prioritizing both maintenance and management practices, businesses can maximize the output of their KUKA machines and achieve higher levels of operational excellence.

Innovative KUKA Technologies Driving Future Production Optimization

Innovative KUKA Technologies Driving Future Production Optimization

In today’s fast-paced manufacturing landscape, KUKA machines are at the forefront of technological advancement, revolutionizing production processes. According to a recent report by the International Federation of Robotics (IFR), the global adoption of industrial robots is expected to grow by 10% annually, underscoring the increasing reliance on automation. KUKA's diverse range of robotics solutions, such as the KUKA LBR iiwa and KUKA KMR iiwa, are designed to enhance collaborative manufacturing, enabling seamless human-robot interaction that optimizes productivity without compromising safety.

Tip: To maximize the efficiency of your KUKA machines, consider implementing predictive maintenance strategies. By utilizing KUKA's Smart Production technologies that integrate AI and machine learning, manufacturers can foresee equipment malfunctions and minimize downtime, ultimately increasing production rates.

Additionally, KUKA's innovative software solutions, such as KUKA.Works, provide real-time data analytics that empower companies to monitor performance metrics and adjust operations dynamically. A study by McKinsey highlights that companies utilizing data-driven decision-making could see their productivity increase by up to 20%. Embracing these technologies not only improves output but also enhances the overall agility of production systems in adapting to market demands.

2025 How to Optimize Your Production with KUKA Machines Efficiently - Innovative KUKA Technologies Driving Future Production Optimization

| Production Aspect | Current Efficiency (%) | Optimization Potential (%) | Recommended KUKA Technology |

|---|---|---|---|

| Machine Speed | 75 | 15 | KUKA High-Speed Robotics |

| Energy Consumption | 85 | 20 | KUKA Energy Efficiency Solutions |

| Production Cycle Time | 60 | 30 | KUKA Automation Software |

| Quality Control | 90 | 10 | KUKA Vision Systems |

| Downtime | 20 | 40 | KUKA Predictive Maintenance Tools |