2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

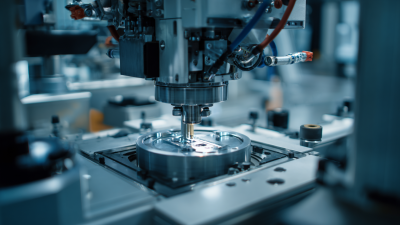

In the ever-evolving landscape of manufacturing, optimizing efficiency in sheet metal processing has become paramount. The

cut to length machine sheet metal is a pivotal piece of equipment

that can significantly enhance productivity when properly calibrated and utilized. According to John Peterson, a renowned expert in sheet metal fabrication,

"Maximizing the efficiency of your cut to length machine is not just about speed; it’s about precision

and consistency to ensure quality output."

His insights highlight the multifaceted nature of optimizing these machines.

As manufacturers strive to meet increasing demands while maintaining quality standards, understanding the intricacies of cut to length machinery becomes essential. This article aims to explore the top ten strategies for optimizing your cut to length machine sheet metal, addressing key factors that influence operational efficiency. From adjusting settings for different materials to implementing regular maintenance schedules, these strategies will provide valuable guidance for engineers and production managers seeking to improve their processes.

By focusing on these optimization techniques, industry professionals can significantly reduce waste, enhance the accuracy of their cuts, and ultimately achieve a more streamlined workflow. In an era where efficiency equates to competitive advantage, the knowledge and implementation of best practices for cut to length machines will prove invaluable in driving success in the sheet metal industry.

Understanding the Importance of Sheet Metal Cut to Length Optimization

Optimization of cut to length processes in sheet metal is critical for enhancing efficiency and reducing waste. As the demand for precision and cost-effectiveness in metal fabrication rises, understanding the significance of optimization becomes paramount. Advanced techniques such as laser cutting have shown promise in achieving better quality and minimizing kerf, which is crucial for materials like stainless steel that exhibit unique challenges due to their ductility.

In recent studies, the exploration of laser cutting parameters has revealed that adjusting cutting speed and focus can significantly influence surface roughness and the overall geometry of the cut. This aligns with the growing trend of utilizing high-power fiber lasers, which offer improved capabilities. Additionally, methods such as machine learning for optimizing material nesting have gained traction, allowing fabricators to make more efficient use of their materials, ultimately contributing to lower production costs and enhanced competitiveness in the market. By embracing these optimization strategies, metal manufacturers can navigate the complexities of modern production demands effectively.

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

| Parameter | Value | Importance |

|---|---|---|

| Cutting Speed (m/min) | 50 | High |

| Sheet Thickness (mm) | 2 | Medium |

| Machine Downtime (%) | 5 | High |

| Material Yield (%) | 90 | High |

| Setup Time (min) | 15 | Medium |

| Operational Efficiency (%) | 95 | High |

Key Technologies Enhancing Cut to Length Machine Efficiency

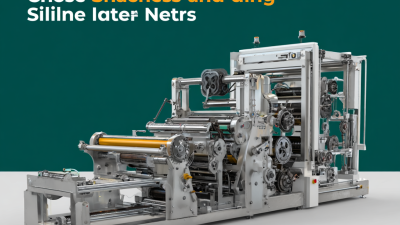

The landscape of sheet metal processing is evolving with the integration of advanced digital manufacturing technologies. These innovations not only streamline operations but also enhance the efficiency of cut-to-length machines. For instance, the use of CNC plasma cutting technology has garnered significant interest, as projected market studies indicate a robust growth trajectory, with increasing applications across various sectors. The adoption of these technologies has led to improved productivity, significant reductions in waste, and enhanced precision in metal fabrication.

**Tips for Optimization:**

To maximize the efficiency of your cut-to-length machine, consider investing in sensor-based monitoring systems that provide real-time data analytics. This allows for proactive adjustments during the cutting process, ensuring optimal settings and minimizing downtime. Moreover, integrating automation solutions can facilitate smoother operations by synchronizing material handling and cutting functions.

In addition, the South & Central American market for servo motors and drives demonstrates the importance of energy efficiency and automation in industrial applications. As the demand for smarter manufacturing solutions continues to rise, leveraging these cutting-edge technologies will be key to maintaining competitive advantage in the sheet metal industry. Emphasizing energy-efficient practices not only boosts operational performance but also aligns with global sustainability goals.

Optimizing Cut to Length Machine Efficiency for Sheet Metal

Best Practices for Maintenance and Upkeep of Cutting Equipment

Regular maintenance is crucial for optimizing the cut to length machine in sheet metal processing. One of the best practices is to establish a routine inspection schedule. This involves checking critical components like blades, alignment mechanisms, and sensors. Ensuring that blades are sharp and free of nicks not only extends their lifespan but also maintains precision in cuts, reducing waste. Additionally, regularly inspecting the machine's alignment can prevent uneven cuts, which can compromise product quality.

Lubrication is another vital aspect of maintenance. Properly lubricating moving parts minimizes friction and wear, which enhances the machine's efficiency. It's essential to use the recommended lubricants and to follow manufacturer guidelines on frequency and application techniques. Furthermore, keeping the machine clean from debris and metal shavings helps to avoid any clogs and operational disruptions. With consistent upkeep, operators can significantly boost the reliability and performance of their cutting equipment, leading to improved efficiency and productivity in sheet metal operations.

Data-Driven Strategies for Improving Production Throughput

The integration of digital twin technology significantly enhances manufacturing efficiency, particularly in the optimization of cut to length machines for sheet metal. By leveraging advanced simulation designs and high-resolution modeling, manufacturers can achieve precise and streamlined production processes. These capabilities not only enhance operational accuracy but also facilitate innovative applications in product design and development, leading to improved production throughput.

Furthermore, the concept of smart factories is pivotal in driving this transformation. By creating a network of interconnected machinery and cutting-edge technologies, manufacturers can automate processes and enhance decision-making. This interconnectedness fosters a data-driven environment where real-time analytics inform production adjustments, ultimately optimizing workflows and maximizing efficiency. As the manufacturing sector increasingly adopts these technologies, the potential for significant growth and innovation becomes evident.

Future Trends in Automation for Sheet Metal Cutting Processes

As the sheet metal industry continues to evolve, automation technologies play a crucial role in enhancing operational efficiency and precision. In a recent report by MarketsandMarkets, the global sheet metal processing market is projected to reach USD 250 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth is largely driven by advancements in automation that streamline cutting processes, improve productivity, and reduce material waste.

Future trends in automation for sheet metal cutting processes include the integration of Artificial Intelligence (AI) and machine learning algorithms. These technologies enable real-time monitoring and adaptive control of cutting machines, ensuring optimal performance. According to a study by Technavio, the implementation of advanced robotics in sheet metal cutting is expected to decrease operational costs by up to 30%, while significantly increasing throughput. Additionally, the adoption of Industry 4.0 principles suggests that interconnected machines will share data seamlessly, allowing for predictive maintenance and minimizing downtime. With such innovations, manufacturers can not only boost efficiency but also stay competitive in a rapidly changing market landscape.