Why Metal Processing Machines are Essential for Modern Manufacturing?

In the rapidly evolving landscape of modern manufacturing, metal processing machines play a crucial role. Experts like Dr. John Mercer, a leading authority in industrial automation, emphasize their importance. He once stated, "Without advanced metal processing machines, innovation in manufacturing would stall."

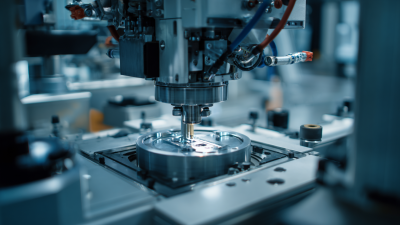

These machines enhance efficiency and precision. They shape, cut, and assemble metal components with remarkable accuracy. However, not all manufacturers utilize these machines effectively. Some overlook the necessity of regular maintenance. This can lead to unexpected downtime and increased costs.

Moreover, the learning curve associated with new metal processing machines may deter some operators. Investing in training is essential. A well-trained workforce can optimize machine capabilities, driving production forward. The urgency for adaptation cannot be understated. Embracing metal processing technology is no longer optional; it is vital for survival in a competitive market.

Importance of Metal Processing Machines in Modern Manufacturing

Metal processing machines play a vital role in modern manufacturing. They help shape raw materials into usable parts. Statistics show that over 80% of industrial products require some form of metal processing. This high demand underscores the importance of these machines.

In recent years, the global market for metal processing machinery has grown significantly. Reports indicate a projected CAGR of around 5.1% through 2026. This growth highlights the need for efficiency and precision in production. However, many companies still struggle to adopt advanced technologies, risking their competitive edge. Despite available solutions, some hesitate to invest, fearing high costs or complicated setups.

Metal processing machines also improve sustainability. Many modern devices reduce waste and energy consumption. Yet, there is still a long way to go. Not all manufacturers have switched to environmentally friendly practices. The challenge is to balance technology, cost, and ecological responsibility. The future demands innovation, but the path remains uneven.

Importance of Metal Processing Machines in Modern Manufacturing

| Dimension | Description | Examples |

|---|---|---|

| Precision | Metal processing machines provide high precision in cutting and shaping metal components. | CNC Machining, Laser Cutting |

| Efficiency | Modern machines greatly reduce production time and waste, enhancing overall efficiency. | Automated Workflow, Robotic Process Automation |

| Versatility | These machines can process a wide range of materials and designs, making them adaptable to various needs. | Lathes, Mills, Waterjet Cutters |

| Cost-Effectiveness | Initial investment in machines can lead to significant long-term savings due to efficiency gains. | Minimized Waste, Reduced Labor Costs |

| Quality Control | Utilizes advanced technology to ensure consistent quality in manufactured products. | Quality Assurance Software, Inspection Systems |

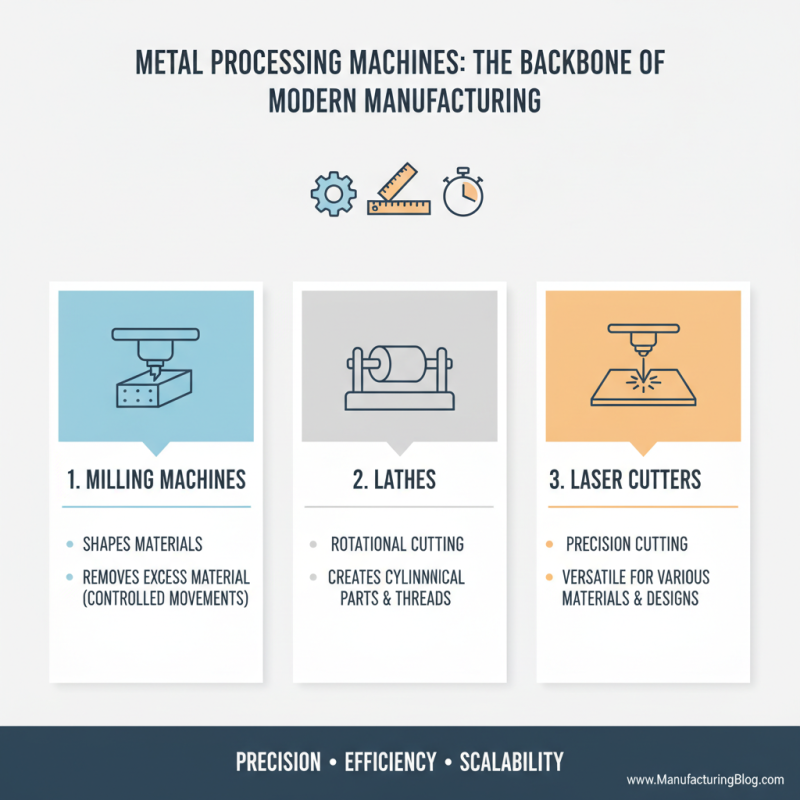

Key Types of Metal Processing Machines and Their Functions

Metal processing machines play a crucial role in modern manufacturing. They ensure precision, efficiency, and scalability in production processes. Key types include milling machines, lathes, and laser cutters. Each has unique functions that cater to specific needs. For instance, milling machines are essential for shaping materials. They remove excess material through controlled movements.

Data from industry reports show that the global metalworking machine market is expected to reach $100 billion by 2025. This growth reflects a rising demand for automation and high-quality output. Laser cutters are particularly noteworthy. They allow for intricate designs and can work with various materials. Their accuracy can reduce waste, but they also require skilled operators. The need for expertise highlights a potential gap in workforce training.

Lathes, another vital component, excel in producing cylindrical parts. They rotate the workpiece against cutting tools, shaping metal effectively. According to recent statistics, lathes account for nearly 25% of all metal processing machinery sold. Despite their importance, many manufacturers struggle to integrate advanced technologies. This shortcoming can hinder overall productivity. Understanding these machines and their functions is essential for staying competitive.

Advancements in Technology Impacting Metal Processing Machinery

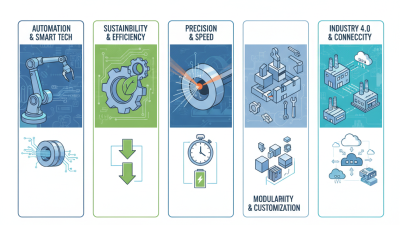

Advancements in technology have revolutionized metal processing machinery. Automation and robotics dominate the modern manufacturing landscape. Machines can now operate with minimal human intervention, improving precision and efficiency. These innovations meet the growing demands of industries like aerospace and automotive.

Metal processing machines now feature advanced materials and controls. For instance, CNC technology allows for intricate designs. Operators can program complex shapes with astounding accuracy. However, reliance on technology poses risks. A system failure can halt production entirely.

Moreover, software integration enhances real-time monitoring. Data analytics provide insights into machine performance. Yet, not all companies adapt quickly to these changes. Training workers to use new systems remains a challenge. Sometimes, businesses overlook the human element in this technological race.

Advancements in Metal Processing Machinery

Role of Metal Processing in Supply Chain Efficiency

Metal processing plays a crucial role in enhancing supply chain efficiency. By converting raw materials into precision components, manufacturers can streamline their production processes. This efficiency reduces lead times, which is vital in today's fast-paced market.

For instance, CNC machines offer high precision and automation. They can produce parts with minimal human intervention, reducing the chances of errors. However, the initial setup and programming can be a challenge. Improperly calibrated machines may lead to waste and increased costs. This issue requires constant monitoring and adjustments.

Moreover, effective metal processing relies on seamless coordination with other supply chain elements. Delays in material supply can hinder production timelines. Hence, manufacturers must cultivate strong relationships with suppliers. Transparency in communication is key. Striking this balance remains an ongoing struggle for many in the industry.

Future Trends in Metal Processing for Industry 4.0 Integration

The advent of Industry 4.0 marks a significant shift in metal processing. Smart manufacturing integrates advanced technologies like IoT, AI, and automation. According to a study by McKinsey, businesses embracing these technologies could see productivity improvements of up to 30%. This indicates a transformative potential for metal processing operations.

Metal processing machines must adapt to this new landscape. Real-time data collection is crucial. Systems that monitor machinery can detect wear and tear instantly, reducing downtime by 25%. Additionally, predictive maintenance can enhance efficiency. Yet, many manufacturers struggle with data integration. This reflects a broader challenge in embracing technological advancements.

Tip: Invest in training for your workforce. Understanding new technology is vital for maximizing its benefits.

There's also a growing trend toward sustainability. Manufacturers are focusing on eco-friendly practices. A Deloitte report states that 66% of companies aim to reduce their carbon footprint. However, implementing sustainable practices can be costly. The transition can be difficult, yet it is necessary for future viability.

Tip: Start small with sustainability initiatives. Gradually scale up as processes become more streamlined.

Related Posts

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

Top Tips for Choosing the Right Rolling Mill Machine?

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

Essential Tips for Choosing the Right Cold Rolling Machine Manufacturer

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

Top Factors to Consider When Choosing a Roll Straightening Machine