What is a Metal Processing Machine and How Does It Work?

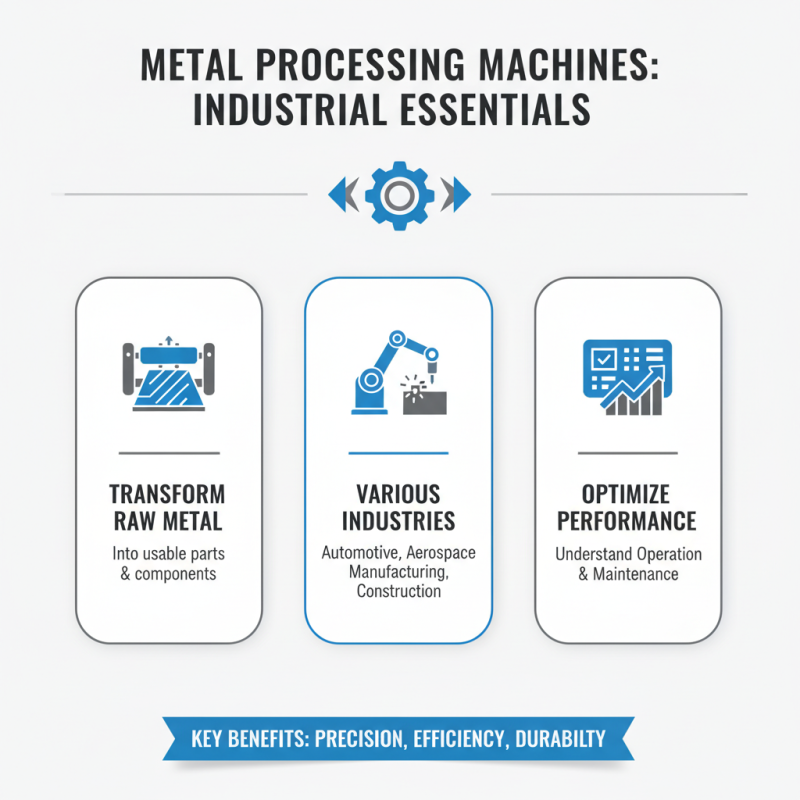

A metal processing machine is a vital tool in manufacturing and fabrication. It transforms raw metals into usable forms. These machines play a crucial role in various industries, including automotive, aerospace, and construction.

Understanding how a metal processing machine functions is essential. It involves processes like cutting, bending, and shaping metals. Each process uses different techniques and equipment. For example, milling machines and lathes create specific shapes and finishes. However, their operation can be complex.

Many might assume that using a metal processing machine is straightforward. In reality, it requires skill and knowledge. Mistakes can lead to waste or defective products. It's important to reflect on the learning process when operating these machines. Knowing the potential issues helps improve efficiency and quality in metalworking.

What is Metal Processing Machine?

Metal processing machines are vital in manufacturing. They shape, cut, and refine metals to create various products. These machines range from simple tools to complex equipment. Understanding their function is crucial for anyone in the industry.

A metal processing machine operates through various techniques. Machining is one method where tools remove material to achieve desired shapes. Welding joins metal pieces using heat. Each technique requires precision and skill. It's interesting how a simple flaw can ruin a project, emphasizing the importance of attention to detail.

Tips: When using metal processing machines, always prioritize safety. Proper training prevents accidents. Regular maintenance is essential for efficiency and precision. Don't ignore signs of wear on parts; even small issues can lead to significant problems. Reflect on your techniques and seek improvement. Continuous learning is key in this field.

Types of Metal Processing Machines and Their Functions

Metal processing machines are essential in various industries. They help shape and manipulate different types of metal. Each machine has unique functions tailored for specific tasks.

CNC machines excel at precision cutting. They follow programmed instructions from a computer, ensuring accuracy.

Press brakes bend metal sheets into desired forms. This process requires both skill and the right machine settings. Additionally, lathes rotate metal, allowing the operator to shape it as needed.

Welding machines fuse metals together using heat. They create strong joints for structural components. However, operating these machines requires training due to safety risks. Understanding each machine's purpose enhances productivity. Yet, that knowledge is often overlooked, leading to mistakes in the workshop. Observing how these machines interact with materials can foster better results and greater safety awareness.

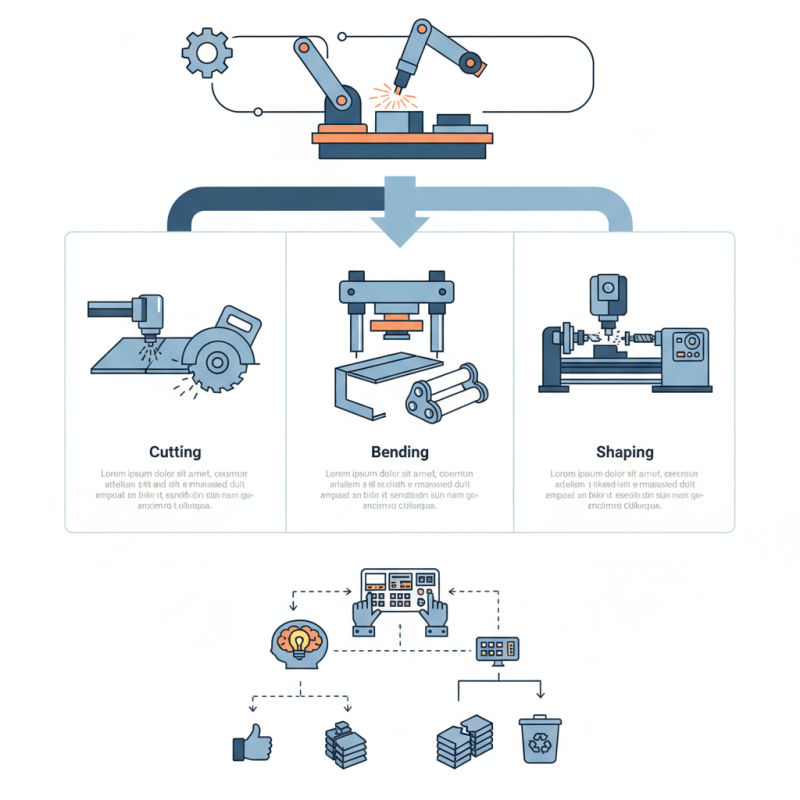

Basic Principles of How Metal Processing Machines Operate

Metal processing machines are essential in various industries. They transform raw metal into usable parts. Understanding their operation helps in optimizing performance.

These machines generally rely on basic principles such as cutting, bending, and shaping. Each process has specific techniques. For instance, cutting can be done using blades, lasers, or water jets. Bending typically involves pressing metal into a desired shape. Each machine type serves a distinct purpose.

Tips: Regular maintenance is crucial. Check for worn parts often. This prolongs machine life and improves safety. Operators should undergo training to handle machines properly. Improper use can lead to accidents or less efficiency.

In practice, metal processing can be straightforward yet challenging. Inattention to detail may lead to errors. Even small mistakes cause significant issues. Always review finished products. It ensures that specifications are met.

Common Applications of Metal Processing Machines in Industry

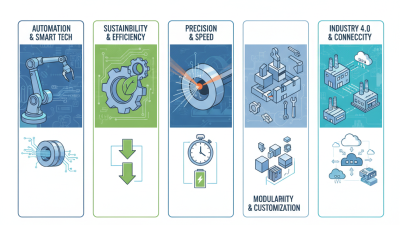

Metal processing machines play a crucial role in various industries. These machines shape, cut, and grind materials to create intricate parts. In the automotive industry, for instance, metal processing is essential for manufacturing components such as engine blocks and transmission parts. According to a recent report, around 69% of automotive manufacturers rely heavily on advanced metal processing technologies.

In aerospace, the precision of metal processing machines is critical. They help produce lightweight and strong components that meet strict safety standards. The demand for processed metals in this sector has increased by 4.7% annually, driven by advancements in machine technology and material science. However, challenges persist, such as the high energy consumption of these machines and the need for skilled operators.

Construction also benefits significantly from metal processing machines. Steel beams and frames are cut and shaped to meet specific design guidelines. Unfortunately, not all companies adopt the latest technologies. Many still use outdated machines. This can lead to inefficient production and increased waste. Industry experts emphasize the need for modernization to improve overall efficiency and reduce environmental impact.

Common Applications of Metal Processing Machines in Industry

Maintenance and Safety Considerations for Metal Processing Machines

Metal processing machines play a critical role in manufacturing. However, their maintenance and safety should never be overlooked. Regular checks can prevent accidents and prolong machine life.

Tip: Always wear appropriate personal protective equipment when operating these machines.

Routine inspections should focus on wear and tear. Look for any loose bolts or damaged components. Inspecting electrical systems is just as vital. Faulty wiring can lead to serious hazards. Operators must be trained to recognize signs of danger. This awareness helps maintain a safe working environment.

Tip: Schedule maintenance during off-peak hours. This avoids disruptions and allows thorough checks.

Keeping a maintenance log can be a game-changer. Documenting issues can reveal patterns that need attention. It’s essential to encourage a culture of safety among all employees. A reluctance to speak up about problems can lead to dire consequences. Always prioritize safety over efficiency.

What is a Metal Processing Machine and How Does It Work? - Maintenance and Safety Considerations for Metal Processing Machines

| Machine Type | Function | Maintenance Frequency | Safety Gear Required |

|---|---|---|---|

| CNC Milling Machine | Precise cutting of materials | Daily | Safety glasses, gloves, ear protection |

| Laser Cutting Machine | High-accuracy cutting using laser technology | Weekly | Protective eyewear, welding mask, gloves |

| Press Brake | Bending sheet metal to desired angles | Monthly | Steel-toed boots, gloves, ear protection |

| Injection Molding Machine | Creating parts by injecting plastic into molds | Daily | Face mask, gloves, protective clothing |

| Milling Machine | Rotary cutting of materials | Weekly | Apron, gloves, goggles |

Related Posts

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

Essential Tips for Choosing the Right Cold Rolling Machine Manufacturer

-

Top Factors to Consider When Choosing a Roll Straightening Machine