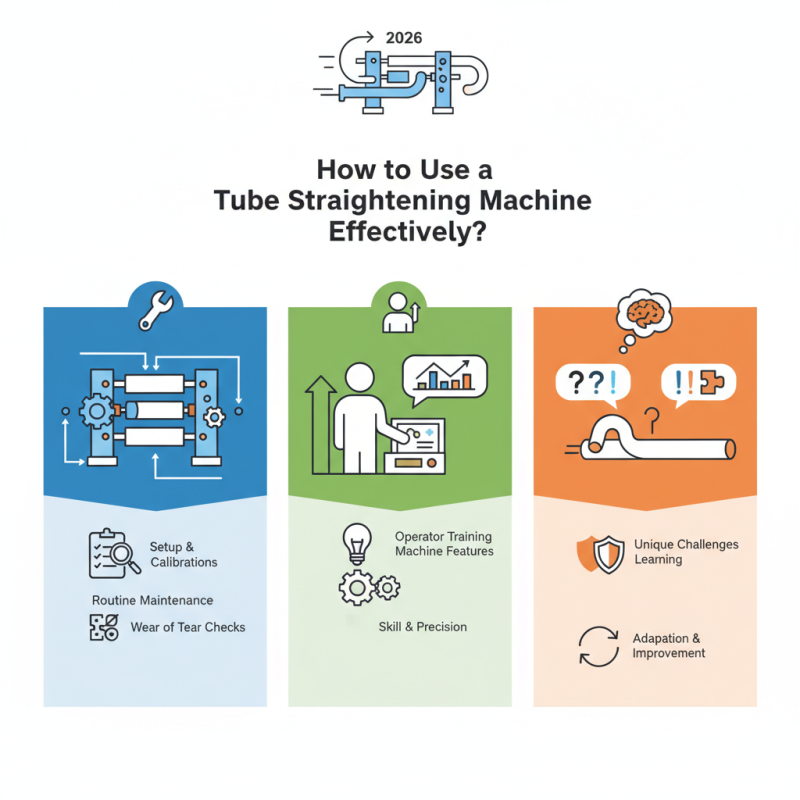

2026 How to Use a Tube Straightening Machine Effectively?

A tube straightening machine plays a vital role in various manufacturing processes. Utilizing this equipment effectively can significantly enhance productivity. Straightening tubes is not simply about aligning them; it requires precision and skill.

Proper setup is crucial. The machine must be adjusted according to the specific dimensions and materials of the tubes. Incorrect settings can lead to failures or damage, impacting overall efficiency. A common mistake is overlooking routine maintenance, which can affect the machine’s performance. Users should regularly check for wear and tear to ensure optimal operation.

Operators need training to use the tube straightening machine effectively. Knowledge about the machine’s features helps prevent accidents. Sometimes, operators may feel overconfident, leading to carelessness. Realizing that each tube may present unique challenges is essential. Continuous learning and adjustment will improve both skill and results in tube straightening tasks.

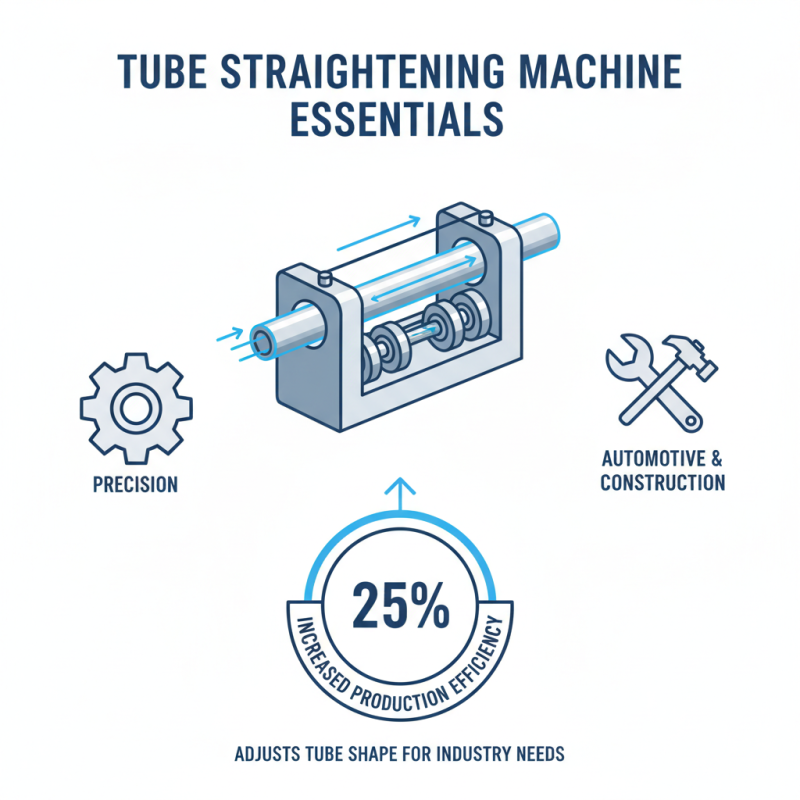

What is a Tube Straightening Machine and Its Functionality?

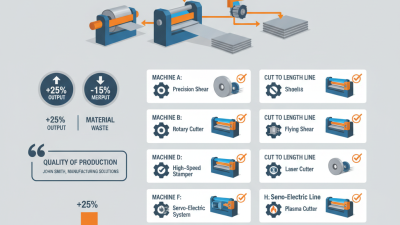

A tube straightening machine is essential in various industries. It adjusts the shape of metal tubes to meet specific requirements. These machines are crucial in sectors like automotive and construction, where precision matters. According to recent industry reports, a well-calibrated tube straightening machine can improve production efficiency by up to 25%.

When using a tube straightening machine, proper setup is vital. Ensure that the machine is calibrated based on the tube specifications. This calibration enhances accuracy and quality in the final product. Also, consider the tube material. Different metals require unique handling techniques.

Tips: Regular maintenance is key. Inspect components for wear and tear. A worn-out machine can lead to inaccuracies in tube shape. This can increase waste and production costs.

Another important factor is operator training. A knowledgeable operator can significantly reduce the chances of mistakes. Aim for continuous learning. Updating skills can help in tackling new challenges. It’s essential to reflect on past experiences and learn from any inefficiencies faced during operation.

Essential Components of a Tube Straightening Machine

A tube straightening machine is essential in metalworking. Understanding its components is crucial for effective use. The main parts include the feed mechanism, straightening rollers, and control panel. Each part plays a vital role in achieving precise results.

The feed mechanism guides the tube through the machine. It ensures a consistent speed and alignment. Poor alignment can lead to uneven straightening. This issue often requires a second pass, wasting time and resources. Straightening rollers apply pressure to correct bends and twists. Choosing the right material and size of these rollers is important. They must match the tube’s specifications to maximize efficiency.

The control panel is where adjustments are made. Operators monitor settings such as speed and pressure. Misjudged settings can cause damage or insufficient straightening. Regular maintenance is also key. Keeping components clean and well-lubricated reduces wear over time. Reflecting on operational processes can help identify areas for improvement.

2026 How to Use a Tube Straightening Machine Effectively? - Essential Components of a Tube Straightening Machine

| Component | Description | Importance |

|---|---|---|

| Straightening Rollers | Mechanical elements that exert pressure on the tube, correcting bends and curves. | Critical for achieving the desired precision and straightness. |

| Feeding System | Mechanism that controls the entry of the tube into the machine for consistent processing. | Ensures uniformity and efficiency in operation. |

| Control Panel | Interface for operators to input parameters and monitor machine performance. | Enhances usability and operational accuracy. |

| Alignment Guides | Assist in positioning the tube correctly for effective straightening. | Important for reducing misalignment and ensuring quality. |

| Power Supply | Provides energy for the machine to operate smoothly and efficiently. | Essential for the performance of all mechanical components. |

Step-by-Step Operation Guide for Effective Tube Straightening

When using a tube straightening machine, precision is key. Follow this step-by-step guide to ensure effective tube straightening. Check the tube for any pre-existing defects before starting. Proper inspection prevents damages during the straightening process. According to recent industry reports, up to 15% of tubes can exhibit imperfections, compromising the final product.

Tips: Always clean the tube thoroughly. Dust or debris can lead to uneven straightening. Ensure the machine settings are correct for the tube material. Settings vary by thickness and diameter. A slight miscalibration can result in a poorly straightened tube.

Load the tube carefully into the machine. Misalignment is a common issue that can cause unnecessary bends. Activate the machine slowly at first. Monitor the progress closely, as excessive pressure can risk damaging the tube. Remember: a straightened tube can maintain structural integrity of up to 20% more than a warped one, according to statistics.

Tips: Keep the machine well-maintained. Regular checks can prevent mechanical failures that hinder productivity. After straightening, inspect the tubes again. This ensures no new defects have cropped up. Continuous improvement in work processes is crucial. Reflect on each operation to enhance your technique moving forward.

Common Challenges and Solutions in Tube Straightening Process

In the tube straightening process, operators often face several challenges. One common issue is uneven feed. This can cause inconsistent straightening results. Adjusting the feed rate is essential. It requires careful calibration but can lead to better outcomes.

Another challenge involves tube material variations. Different materials respond inconsistently to straightening. For instance, softer materials may bend more easily, while harder tubes resist deformation. Understanding the specific characteristics of each tube helps. It allows operators to customize their approach, making adjustments as needed.

Lastly, machine maintenance is crucial. Neglecting maintenance can lead to performance issues. Worn rollers or misalignment can sabotage straightening efforts. Frequent checks and replacements are necessary. This may seem tedious, but it ensures long-term efficiency. Operators must reflect on their processes to identify and rectify such oversights.

Maintenance Tips for Long-lasting Performance of Tube Straightening Machines

Maintaining a tube straightening machine is crucial for its longevity. Regular inspections are essential. Check for wear and tear on rollers and guides. Often, operators overlook minor damages. These small issues can escalate if ignored. Replace worn parts promptly to avoid breakdowns.

Lubrication is another vital aspect. Use the recommended lubricants for moving parts. Insufficient lubrication can lead to friction and overheating. Surprisingly, many users underestimate the importance of regular lubrication. Implement a consistent schedule based on usage. Clean the machine regularly to prevent dust buildup. Dust can interfere with performance over time.

Training staff on proper operation is key. Workers should understand how to use the machine effectively. Misuse can lead to unnecessary wear. Often, a lack of knowledge results in mistakes. Regular training sessions can help avoid this. Proper maintenance practices will enhance efficiency and lifespan.

Related Posts

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

What is a Roller Leveling Machine and How Does It Work?

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

Top 10 Cut to Length Line Machines for Efficient Manufacturing Solutions?