What is a Hot Rolling Mill Machine and How Does it Work?

Hot rolling mills are essential in the metalworking industry. These machines shape materials at high temperatures, transforming them into various forms. A hot rolling mill machine processes metals, often steel, to create sheets, plates, and bars.

The operation of a hot rolling mill machine involves several crucial steps. Initially, large metal billets are heated to a specific temperature. This softens the metal, making it easier to shape. When pushed through rolls, the metal is reduced in thickness and elongated. The result is a final product that meets industry standards.

Understanding how these machines work reveals insights into their efficiency. Yet, limitations exist. Not all materials respond well to hot rolling. Some metals require alternative processes. Therefore, careful consideration is necessary when selecting methods for specific applications. Ultimately, the hot rolling mill machine plays a pivotal role in manufacturing, despite its complexities and challenges.

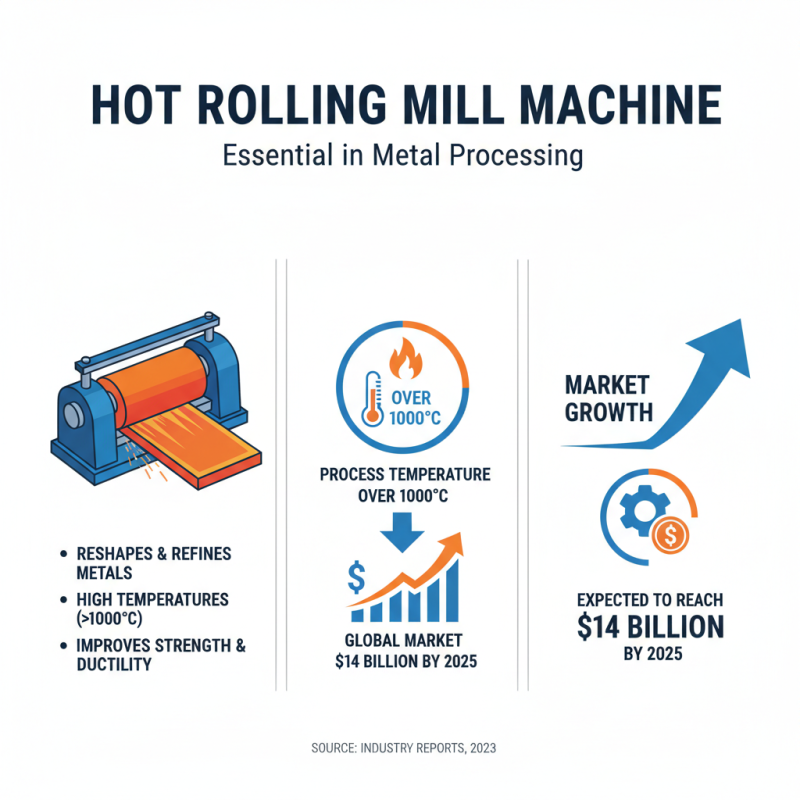

Definition and Purpose of a Hot Rolling Mill Machine

A hot rolling mill machine is essential in metal processing. It reshapes and refines materials at high temperatures. This process improves metal properties, such as strength and ductility. The temperature usually exceeds 1,000 degrees Celsius during operations. According to recent reports, the global hot rolling market is expected to reach approximately $14 billion by 2025, highlighting its importance.

The primary purpose of a hot rolling mill is to produce metal sheets, plates, and bars. It increases material flow and reduces thickness. This process can create products that are more uniform in thickness and more manageable for further processing. However, achieving consistency requires careful monitoring. In practice, slight temperature variations can affect the final product quality. Sometimes, even a small error can lead to significant issues in downstream processes.

Hot rolling mills also have environmental considerations. Energy consumption in these mills is significant. One report suggests that hot rolling mills account for nearly 30% of energy use in steel production. Enhancing energy efficiency is a challenge. Many mills are exploring innovative technologies to minimize their carbon footprint. However, progress can be slow, as traditional practices are deeply ingrained. Balancing efficiency and innovation remains a pressing concern in the industry.

Key Components of a Hot Rolling Mill System

A hot rolling mill machine plays a crucial role in transforming metal into usable forms. The key components of this system include the furnace, rolling stands, cooling beds, and more. Each part has a distinct function that contributes to efficient metal processing.

The furnace heats the metal to high temperatures. This is essential for malleability. Next, the rolling stands apply pressure to the heated material. They reduce thickness and shape the metal. These stands are adjustable, allowing flexibility in the production of various metals.

Tip: Regular maintenance of the rolling stands can prevent costly downtime. Ensure that the pressure settings are checked frequently to maintain consistent quality.

Cooling beds follow the rolling process. They quickly lower the temperature of the rolled metal, ensuring it retains the desired shape. Monitoring the cooling rate is important. Uneven cooling can lead to defects.

Tip: Keep an eye on the bed surface for any irregularities. This can affect the final product quality. Each component of the hot rolling mill is vital. Understanding their roles helps improve production efficiency and product consistency.

What is a Hot Rolling Mill Machine and How Does it Work? - Key Components of a Hot Rolling Mill System

| Component | Function | Material Processed | Temperature Range (°C) |

|---|---|---|---|

| Reheating Furnace | Heats metal before rolling | Steel, Aluminum | 1100 - 1300 |

| Reversing Mill | Reduces thickness by rolling in both directions | Steel | 800 - 1200 |

| Finishing Mill | Final shaping and sizing of the product | Steel, Copper | 700 - 1050 |

| Cooling Bed | Cools the rolled product | Steel | Room Temperature |

| Control System | Monitors and controls the rolling process | N/A | N/A |

Operational Process of Hot Rolling in Metal Forming

Hot rolling is a crucial process in metal forming. It involves heating metal above its recrystallization temperature and then shaping it. The typical temperature range for hot rolling is between 1,600°F to 2,200°F (about 870°C to 1,200°C). At such temperatures, metals become malleable. This allows for easier manipulation. The heated metal is passed through a series of rolls. These rolls reduce its thickness and shape it into flat plates, bars, or sheets.

The operational process is extensive. First, the metal is heated in a furnace. This initial stage is vital. Uniform heating ensures that no weak spots develop. After heating, the metal enters the rolling mill. Here, it undergoes deformation. The entire process can achieve thickness reduction of up to 90% in a single pass. However, achieving uniform thickness can be challenging. Variations can lead to defects. A report from the World Steel Association highlighted that quality control is crucial, with a focus on maintaining consistent rolling conditions.

Temperature control is also essential. Too high a temperature can damage the material, leading to fractures. On the other hand, too low a temperature results in undesirable mechanical properties. Statistics show that improper rolling temperatures contribute to over 15% of product failures in the industry. Hot rolling requires precision and experience. Each step is interconnected, and overlooking any detail can compromise the final product.

Hot Rolling Mill Operational Process Overview

This chart illustrates key parameters involved in the hot rolling process of metal forming, including temperature, rolling force, speed, thickness reduction, and yield strength. These parameters are crucial for ensuring quality and efficiency in metal production.

Advantages of Using Hot Rolling Mill Machines

Hot rolling mills are essential in the metalworking industry, producing a range of products. These machines can handle materials at high temperatures, which allows for easier shaping. This process can enhance the mechanical properties of metals, making them more suitable for various applications.

One key advantage of using hot rolling mill machines is the significant reduction in manufacturing costs. A report by the International Journal of Advanced Manufacturing Technology indicates that hot rolling processes can reduce production costs by up to 30%. This is largely due to the decreased energy consumption during the rolling. Additionally, hot rolling improves material yield. Research shows that yield improvements can reach 15%, which translates to less waste during production.

Another benefit lies in dimensional accuracy. Hot rolling allows for greater precision in thickness, width, and length. This level of accuracy is critical in industries such as automotive and construction, where specific tolerances are mandatory. However, despite these advantages, companies must also address challenges related to thermal management. Inadequate temperature control can lead to defects, necessitating careful monitoring during operations. Balancing cost-saving measures and quality control remains an ongoing concern for many manufacturers.

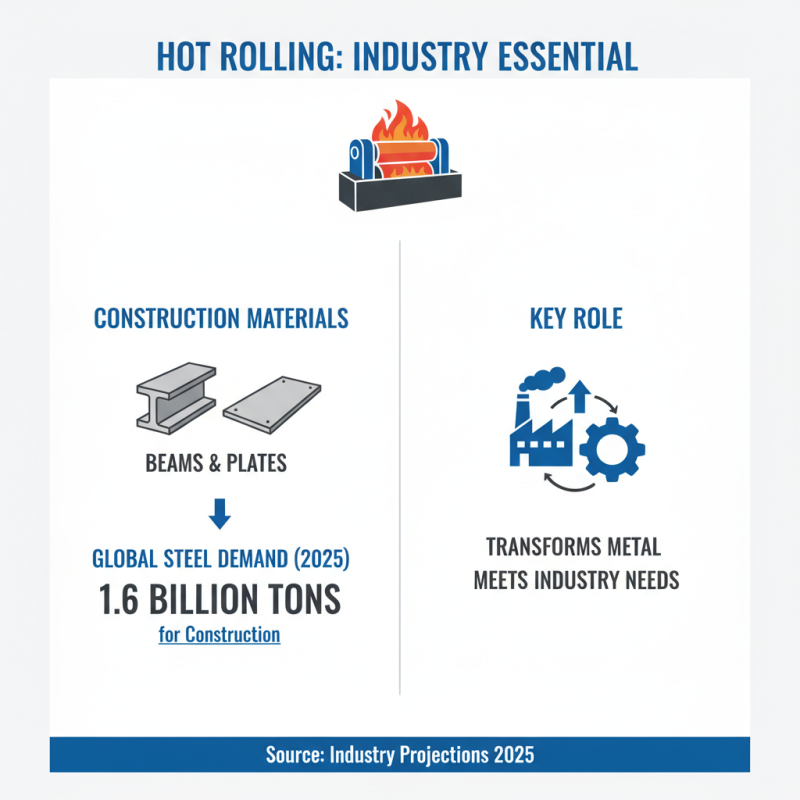

Applications of Hot Rolling in Various Industries

Hot rolling is a crucial process across multiple industries, enabling the transformation of metal into workable forms. In construction, it is extensively used for manufacturing beams and plates. The global demand for steel in construction is projected to reach 1.6 billion tons by 2025. This reflects the pivotal role of hot rolling mills in meeting industry needs.

In the automotive sector, components produced by hot rolling are essential for vehicle manufacturing. The hot rolling process allows for precise dimensions and enhanced properties. Experts note that approximately 70% of steel used in vehicles is hot rolled. This indicates a strong dependency on this process for quality and durability.

However, hot rolling does have its drawbacks. The process can lead to material defects if not carefully monitored. Factors like temperature fluctuations can impact the final product. It's essential to continually assess these issues to refine the process and improve outputs. Even with advanced technology, human supervision remains vital. Understanding the limitations of hot rolling is crucial for future developments in various industries.

Related Posts

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

Top Benefits of Using a Metal Coil Slitting Machine in Manufacturing Industry?

-

Why Is a Profile Straightening Machine Essential for Precision?

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs