Top Factors to Consider When Choosing a Roll Straightening Machine

When it comes to selecting the right roll straightening machine, industry professionals emphasize the importance of making an informed choice. According to John Smith, a renowned expert in metal processing machinery, “The efficiency and effectiveness of a roll straightening machine can significantly impact production quality and operational costs.” This statement highlights the critical role that the right equipment plays in ensuring optimal performance in manufacturing.

A roll straightening machine is not just a tool; it is a vital asset that can determine the overall success of metal fabrication processes. With numerous options available in the market, it is essential for manufacturers to consider key factors such as machine capacity, design flexibility, and ease of maintenance. Each of these elements can influence not only the straightening process but also the longevity and reliability of the machine itself.

As businesses strive for greater efficiency and productivity, understanding the nuances of selecting a roll straightening machine becomes paramount. By prioritizing the right features and capabilities, manufacturers can enhance their operational effectiveness, reduce waste, and ultimately drive profitability in today’s competitive landscape.

Key Specifications to Evaluate in Roll Straightening Machines

When evaluating roll straightening machines, several key specifications demand careful consideration to ensure optimal performance and efficiency in production. One primary factor is the machine's capacity, which refers to the maximum material thickness and width it can handle. According to a report by the International Journal of Manufacturing Technology, machines with a higher capacity typically allow for greater versatility, enabling operations to straighten larger or thicker rolls, thus minimizing the need for multiple units in the production line.

Another critical specification is the level of adjustment and control offered by the machine. Modern roll straighteners incorporate advanced hydraulic systems and programmable logic controllers (PLC) that facilitate precise adjustments during the straightening process. Research indicates that machines featuring such technologies can achieve accuracy within ±0.01 mm, which greatly enhances the quality of the finished product. Furthermore, energy efficiency ratings should also be scrutinized, as machines that consume less energy while maintaining performance levels can lead to significant cost savings over time, aligning with environmental sustainability goals in manufacturing operations.

Lastly, the simplicity and speed of maintenance are vital factors that directly impact downtime and overall productivity. Machines designed with modular components and easy-access features enable quicker repairs and part replacements, leading to minimized operational interruptions. Industry studies have demonstrated that streamlined maintenance approaches can reduce downtime by up to 30%, resulting in higher throughput and more efficient production cycles. This emphasis on design and operational efficiency underscores the significance of selecting a roll straightening machine that not only meets technical specifications but also aligns with the broader strategic goals of manufacturing processes.

Top Factors to Consider When Choosing a Roll Straightening Machine

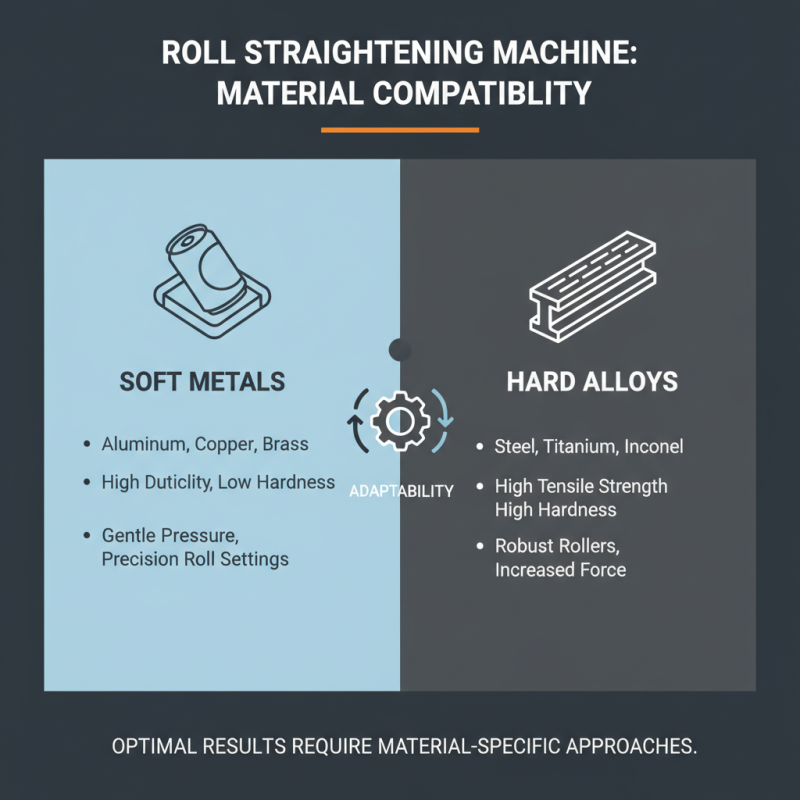

Understanding Material Compatibility for Roll Straightening

When selecting a roll straightening machine, understanding material compatibility is crucial. Different materials have unique mechanical properties, including tensile strength, ductility, and hardness that dictate how they respond to straightening processes. For instance, softer metals like aluminum may require different settings and approaches compared to harder alloys such as steel. Ensuring the machine can accommodate various material types helps in achieving optimal results without causing damage or deformation.

Additionally, the thickness and shape of the material being straightened must be taken into account. A machine that is versatile in handling a range of thicknesses will allow for flexibility in production and minimize the need for multiple machines. Moreover, the geometry of the rolled material can significantly influence the choice of the straightening equipment. Different shapes, such as round or square profiles, may necessitate specific types of rollers or setups to ensure effective straightening. By prioritizing material compatibility during the selection process, operators can enhance efficiency and maintain high-quality standards in their manufacturing operations.

Importance of Machine Precision and Tolerance Levels

When selecting a roll straightening machine, precision and tolerance levels are paramount. The importance of these factors cannot be overstated, as they directly impact the quality and performance of the final product. According to a report by the Manufacturing Institute, machines that are capable of achieving tighter tolerances lead to a 30% reduction in scrap rates, which significantly enhances operational efficiency. Precision in straightening processes ensures that materials maintain their intended dimensions, leading to improved consistency in manufacturing outputs.

Furthermore, industry standards, such as those set by the International Organization for Standardization (ISO), emphasize the necessity of precision in machining processes. For example, components requiring a tolerance level of ±0.01 mm can be critical in industries like aerospace and automotive, where minute inaccuracies can lead to significant performance issues. A study highlighted that deviations beyond specified tolerances can result in costly rework and delays, estimated to reach millions in lost revenue. Therefore, investing in a roll straightening machine with advanced precision capabilities not only ensures compliance with industry standards but also enhances production reliability and customer satisfaction.

Top Factors to Consider When Choosing a Roll Straightening Machine

| Factor | Description | Importance Level | Recommended Tolerance Levels |

|---|---|---|---|

| Precision | The machine's ability to maintain accurate dimensions during operation. | High | ±0.01 mm |

| Tolerance Levels | The allowable deviation from specific dimensions without affecting functionality. | Critical | ±0.02 mm |

| Material Compatibility | The machine's ability to handle different materials without damage. | High | N/A |

| Speed | The rate at which the machine operates, impacting productivity. | Medium | Up to 200 mm/s |

| User-Friendliness | Ease of use and ergonomics of the machine interface. | High | N/A |

| Maintenance Requirements | Frequency and ease of maintenance tasks needed to keep the machine running smoothly. | Medium | Monthly inspections recommended |

Assessing Production Capacity and Speed Requirements

When selecting a roll straightening machine, assessing production capacity and speed requirements is critical to optimizing manufacturing efficiency. The production capacity of the machine should align with the daily output needs of the facility. A thorough analysis of production volumes allows for appropriate machine selection that meets both current and anticipated demands. Operators must consider not only the quantity of material needing processing but also the complexity of the shapes being straightened, which may influence the choice of machine features.

Speed requirements are equally essential in the decision-making process. The straightening process should synchronize with overall production timelines to ensure minimum downtime and maximum throughput. Evaluating the feed rates and the ability of the machine to maintain consistent speeds without sacrificing quality is vital. Moreover, machines that offer adjustable speed settings may provide greater versatility, allowing operators to tailor the performance based on specific project needs or material characteristics. Ultimately, balancing production capacity and speed will lead to enhanced productivity and profitability in any manufacturing environment.

Evaluating Maintenance and Support for Roll Straightening Equipment

When selecting a roll straightening machine, it is crucial to evaluate the maintenance and support offered for the equipment. A well-structured maintenance plan can significantly enhance the lifespan and efficiency of the machine. Look for machines that come with comprehensive maintenance schedules and easy access to replacement parts. Regular maintenance not only helps in preventing unexpected downtimes but also ensures that the machine operates at peak performance.

In addition to maintenance, the quality of technical support provided by the manufacturer is essential. Consider whether they offer prompt assistance in case of equipment issues. A reliable support team should be readily available to troubleshoot problems and provide guidance on best practices for operation. Investing in a roll straightening machine backed by robust after-sales support can save time and reduce costs associated with operational hiccups. Overall, thorough assessments of maintenance capabilities and support systems are vital factors that should influence your purchasing decision.

Related Posts

-

Why You Need a Roll Straightener Machine for Efficient Metal Processing

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry