10 Essential Tips for Using a Roll Straightening Machine Effectively?

Using a roll straightening machine can significantly improve your metal processing efficiency. However, many users struggle to get the best results. Understanding key techniques is crucial for optimal performance.

Proper adjustment of settings is essential. Inadequate settings may lead to material defects. Users often overlook the importance of regular maintenance. Neglecting this can cause breakdowns, affecting production times. It's surprising how minor issues can escalate into major problems.

Tool placement and alignment also play critical roles. Misalignment can result in uneven straightening. Many operators make the mistake of rushing setup, leading to wasted materials. Attention to detail can save both time and resources. Remember, practice makes perfect, but there’s always room for improvement.

Understanding the Basics of a Roll Straightening Machine

A roll straightening machine is a pivotal tool in metal processing. It helps eliminate warping and ensures precision in metal shapes. To understand its basics, one needs to know about its internal mechanics. These machines operate by using a series of rollers, which adjust the material's alignment. According to industry research, a well-calibrated machine can reduce material waste by up to 30%. This efficiency is crucial in high-stakes production environments.

Proper adjustments to the machine's settings are essential. Many operators overlook the importance of consistent roller pressure. Continuously varying pressure can lead to imperfect straightening results. In fact, a recent study highlighted that improper setup can yield a 15% increase in defects. Operators should invest time in understanding the specifications of the machine. This involves regular maintenance and calibration checks, which are often neglected.

The material's characteristics play a vital role too. Different metals behave differently under stress. Some may require more gentle handling. Testing various settings on scrap materials can prevent costly mistakes. If one doesn't experiment and learn, they may continue to face challenges in achieving desired outcomes. Embracing this trial-and-error approach is part of mastering the roll straightening process.

10 Essential Tips for Using a Roll Straightening Machine Effectively

This bar chart presents the effectiveness of different tips for using a roll straightening machine based on user satisfaction ratings. Each tip is rated on a scale of 1 to 10, reflecting how well users feel these tips improve their operation of the machine.

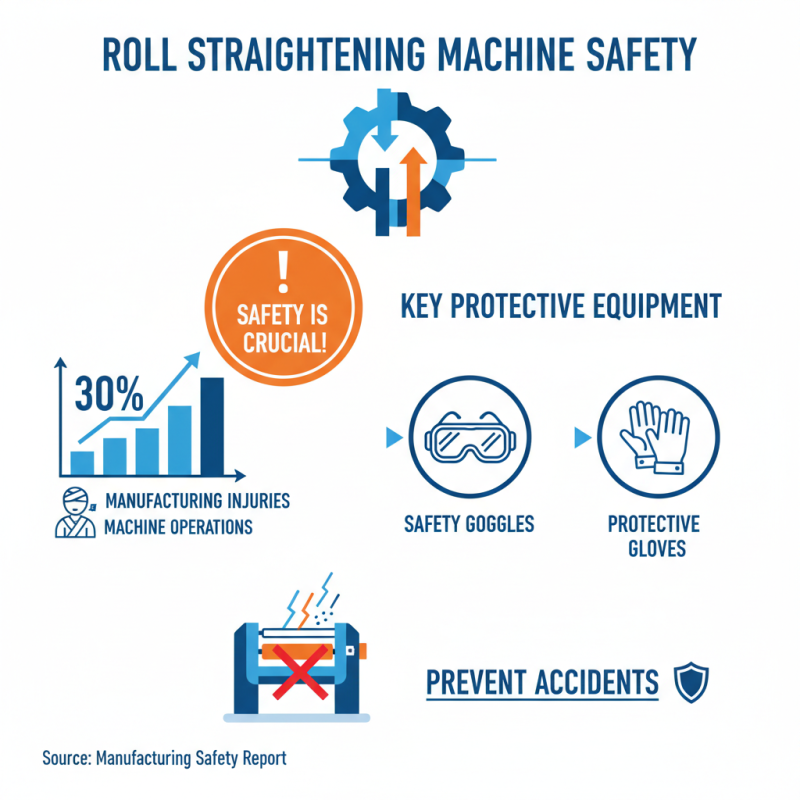

Key Safety Precautions to Follow During Operation

When operating a roll straightening machine, safety is crucial. Reports show that improper handling can lead to accidents, with 30% of injuries in manufacturing linked to machine operations. Begin by wearing appropriate personal protective equipment. This includes safety goggles and gloves to protect against sharp edges and flying debris.

Next, maintain a clean workspace. Clutter can lead to slips or mishaps. Ensure that the machine is in good working order. Regular inspections are key. According to industry standards, machines need maintenance every 500 hours of operation. A well-maintained machine reduces risk and enhances efficiency.

Additionally, be aware of your surroundings. Other workers may be near the machine. Communication is essential. Use clear signals or verbal cues before operating the machine. Keep emergency stops within easy reach. This ensures quick action in case of a malfunction. Remember, safety isn’t just a policy; it is a culture. Taking small steps can make a significant impact on your safety record.

Step-by-Step Setup Process for Optimal Performance

Setting up a roll straightening machine requires attention to detail. Start by ensuring the machine is on a solid, level surface. This is crucial for stability during operation. Studies show that machines on uneven ground can lead to errors in straightening, reducing efficiency by up to 25%. A secure environment enhances both safety and output quality.

Next, calibrate the rolls carefully. Use precise measurements to adjust the roll gap according to the material thickness. An improper gap can result in inadequate straightening. In an industry report, it was noted that misaligned rolls account for over 30% of production issues. After calibration, run a test piece. Inspect the results; this step helps identify potential problems before actual production begins.

Finally, review all settings regularly. Machinery often shifts or wears down over time. Keeping an eye on wear patterns can prevent unexpected downtime. Regular checks can increase the lifespan of the machine by up to 15%. In doing so, you create a more reliable operation while minimizing costly repairs. Remember, even small adjustments can lead to significant improvements in performance.

10 Essential Tips for Using a Roll Straightening Machine Effectively

| Tip Number | Tip | Description |

|---|---|---|

| 1 | Read the Manual | Understand the machine's specifications and operational guidelines. |

| 2 | Check Calibration | Ensure that all measurements are accurate before starting production. |

| 3 | Adjust Roller Pressure | Set the correct pressure based on material type and thickness. |

| 4 | Use Proper Settings | Select the appropriate settings for material size and shape. |

| 5 | Perform Regular Maintenance | Keep the machine clean and well-oiled to prolong its lifespan. |

| 6 | Train Your Operators | Ensure all users are trained on best practices for safety and efficiency. |

| 7 | Monitor Output Quality | Check the finished product for straightness and material integrity. |

| 8 | Optimize Work Environment | Maintain a clean, organized workspace to increase efficiency. |

| 9 | Minimize Downtime | Implement proactive measures to reduce equipment failures. |

| 10 | Gather Feedback | Collect input from operators to improve processes and efficiency. |

Techniques for Adjusting Roll Parameters Effectively

Adjusting roll parameters accurately is crucial for the effective use of a roll straightening machine. Start by understanding material characteristics. Each material behaves differently under pressure. For instance, steel may require different settings compared to aluminum. Carefully measure the material’s thickness and width. This informs the correct roll gap adjustments. A gap that’s too tight can cause deformation, while one that’s too loose may not achieve the desired straightness.

Keep in mind the role of temperature. Materials can expand or contract based on heat. Operating at room temperature often yields the best results. Monitor the machine’s settings during operation. Sometimes, readjustments are necessary. Small tweaks can lead to significant improvements. If results aren’t satisfactory, reflect on your setup. An overlooked parameter could be the reason. Adjustments often require patience and multiple trials to achieve optimal performance. Embrace the learning process; every attempt teaches something valuable.

Maintenance Tips to Ensure Longevity and Efficiency

Regular maintenance of your roll straightening machine is crucial for optimal performance. Start by checking the alignment. Misalignment can lead to uneven results and wear on the machine. Adjusting rollers regularly can save time and costs in repairs. Clean the machine often. Dust and debris can hinder performance. Use a soft brush to remove particles, especially around the rollers.

Lubrication is another vital aspect of maintenance. Apply the right lubricant to moving parts to prevent friction. This keeps the machine running smoothly. Over time, belts may wear out. Inspect and replace them when necessary. A worn belt can cause inaccuracies in straightening. Monitor temperature during operation too. Excess heat can affect metal properties and machine efficiency.

Training personnel is equally significant. Ensure that all operators understand the machine's functions and maintenance needs. Untrained operators may neglect important tasks. Reflecting on past issues can help. Analyze breakdowns and take necessary steps to avoid repetition. Remember that regular check-ups can enhance efficiency and prolong the machine’s life.

Related Posts

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

Why You Need a Roll Straightener Machine for Efficient Metal Processing

-

Top Factors to Consider When Choosing a Roll Straightening Machine

-

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

-

Why Metal Processing Machines are Essential for Modern Manufacturing?