10 Essential Tips for Operating Hot Rolling Mill Machines Effectively?

In the fast-paced world of metal processing, operating hot rolling mill machines effectively is crucial. Expert engineer David Thompson emphasizes, "Precision in operation defines the success of hot rolling mill machines." His insights remind us that even minor details can significantly impact productivity and safety.

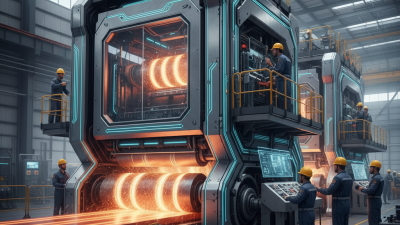

Understanding the intricate mechanics of a hot rolling mill machine is essential. These machines are designed to convert heated metal into desired shapes and sizes. Yet, issues like improper temperature control can lead to substantial defects. Attention to detail is vital in every step of the process.

Moreover, the role of operator training cannot be overstated. Well-trained personnel can identify potential problems before they escalate. In this field, even small adjustments can make a considerable difference. Each operator's commitment to excellence contributes to the overall efficiency of hot rolling mill operations.

Understanding the Basics of Hot Rolling Mill Machine Functions

Hot rolling mill machines play a crucial role in metal processing industries. Understanding their functions is key to maximizing efficiency. These machines convert heated metal slabs into various shapes, such as sheets, rods, and bars. The process involves deforming the material using heat and mechanical power.

Tip 1: Regular maintenance is essential. Check the rollers and hydraulic systems regularly. Wear and tear can cause inefficiencies. Keep an eye on lubrication. Gaps in maintenance could lead to unexpected downtimes.

The operation requires a solid grasp of temperature control. The metal must be at optimal temperatures for effective rolling. Cooling too fast or not enough can lead to defects. This impacts the final product's quality.

Tip 2: Train operators thoroughly. Understanding machine functions ensures safety and boosts productivity. Poor understanding can result in mistakes. Mistakes lead to costly delays and wasted materials.

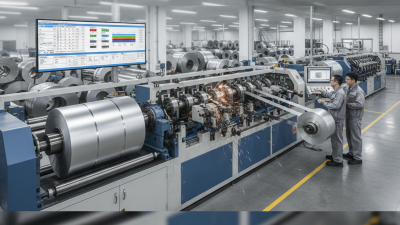

Monitoring output is also important. Keep track of thickness and consistency. Variation can indicate underlying problems, which may go unnoticed. Address discrepancies promptly to maintain quality.

Tip 3: Implement a feedback system. Collect data from operators regularly. This can highlight areas for improvement. Regular reviews can uncover persistent issues that need addressing.

Key Safety Protocols for Operating Hot Rolling Mill Machines

Operating hot rolling mill machines comes with significant safety responsibilities. Workers should always wear protective gear, including helmets, gloves, and heat-resistant clothing. This gear acts as a first line of defense against burns and injuries caused by hot metal. Additionally, it is crucial that everyone on the shop floor understands emergency procedures. Accidents can happen in an instant, and knowing how to respond can make all the difference.

Effective communication is essential in a hot rolling mill environment. Team members must signal clearly during operations, especially when metal is moving. Some workers might forget to communicate in stressful situations. Regular training sessions can help reinforce these critical skills. Also, maintaining a clean workspace is often overlooked. Clutter can lead to accidents, so ensuring clear pathways is vital. Keep an eye out for spills that may cause slips and falls.

Finally, it is important to regularly inspect machinery for wear and tear. Machines are powerful but can be dangerous if not maintained properly. Small issues can escalate quickly. A system for reporting problems should be in place. Encourage a culture where workers feel comfortable raising concerns. Only through continuous vigilance and improvement can safe operation be ensured in such a high-risk environment.

Essential Maintenance Procedures for Hot Rolling Mills

Maintenance of hot rolling mills is crucial. Regular checks can prevent significant breakdowns and enhance efficiency. Each component needs attention. Focus on bearings, rolls, and hydraulic systems. These elements experience heavy wear under intense conditions.

Inspecting the lubrication system often gets overlooked. Proper lubrication reduces friction and heat, extending equipment life. However, many operators neglect this. A simple check can reveal oil levels or contaminants needing attention. Cleaning out filters should be routine but isn't always followed diligently.

Another vital aspect involves monitoring temperature variations. Hot spots can indicate issues in the rolling process. Ignoring these signs may lead to material defects. Operators sometimes miss these critical observations, causing further complications. Training on identifying such signs is necessary. Consistency in maintenance not only prolongs machinery lifespan but also ensures product quality.

10 Essential Tips for Operating Hot Rolling Mill Machines Effectively

| Tip | Description | Frequency | Responsibility |

|---|---|---|---|

| Regular Lubrication | Ensure all moving parts are properly lubricated to reduce friction and wear. | Daily | Maintenance Staff |

| Temperature Monitoring | Constantly monitor the temperature of materials to achieve optimal rolling conditions. | Continuous | Operator |

| Equipment Inspection | Regularly check for wear and tear to prevent unexpected breakdowns. | Weekly | Maintenance Team |

| Roll Space Adjustment | Adjust the gap between the rolls to control material thickness accurately. | Every Shift | Operator |

| Control Roll Speed | Monitor and adjust the rolling speed for optimal processing. | Continuous | Operator |

| Safety Gear Usage | Ensure all personnel wear appropriate safety equipment while operating machinery. | Always | All Staff |

| Plate and Sheet Inspection | Inspect final products for defects and ensure they meet quality standards. | After Production | Quality Control Team |

| Documentation of Maintenance | Maintain detailed records of maintenance work performed on the mill. | Ongoing | Maintenance Staff |

| Training Programs | Regularly train staff on best practices and safety protocols. | Quarterly | Management |

| Emergency Procedures | Make sure all staff are familiar with emergency shutdown procedures. | Annually | All Staff |

Operating Parameters for Optimal Hot Rolling Mill Performance

Operating a hot rolling mill involves precise control over various parameters to achieve optimal performance. Key parameters include rolling temperature, speed, and material properties. Research indicates that maintaining the rolling temperature between 1,600°F and 2,400°F significantly enhances the ductility of steel. This range allows for better deformation and reduces the energy required for processing.

The roll gap is another critical aspect. A consistent roll gap ensures uniform thickness in the final product. Variations can lead to defects and increased scrap rates. Studies show that a roll gap variation of more than 0.1 mm can result in a 5% reduction in yield. Operators must monitor this parameter closely to mitigate inefficiencies.

Rolling speed, too, plays a pivotal role. Optimal speeds can range widely based on the material and desired thickness. Too fast can lead to overheating and equipment wear, while too slow may cause unnecessary downtime. Up to 25% of the operational costs can be attributed to speed-related inefficiencies. These parameters require careful consideration and constant adjustment for peak mill performance.

Troubleshooting Common Issues in Hot Rolling Mill Operations

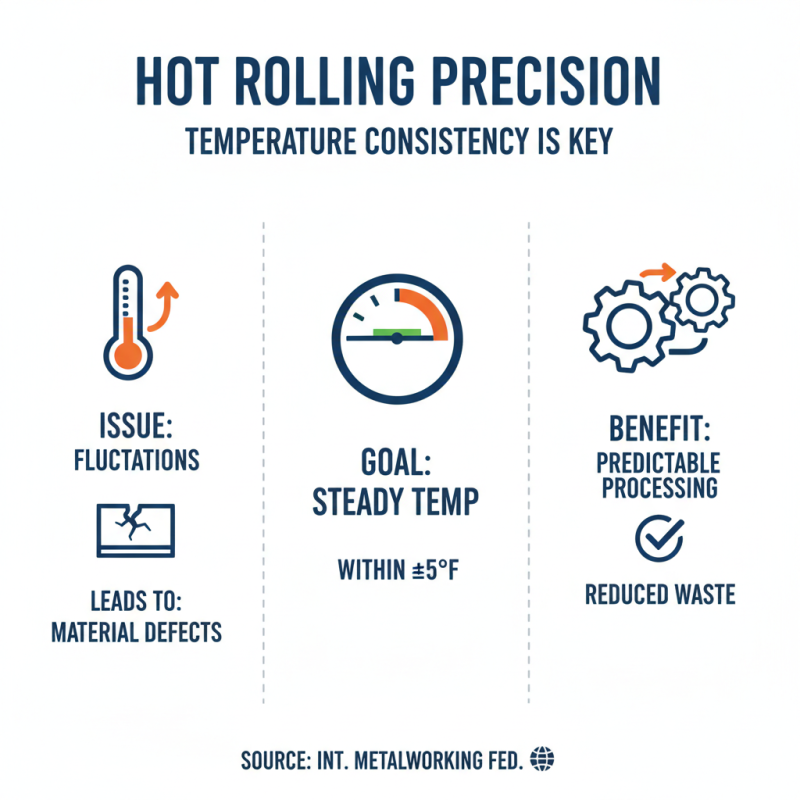

Operating hot rolling mill machines requires precision and attention to detail. One common issue faced in these operations is temperature inconsistency. A recent report by the International Metalworking Federation noted that fluctuations in temperature can lead to material defects. Maintaining a steady temperature within a 5-degree Fahrenheit range is crucial. This level of precision ensures that the material behaves predictably during processing.

Another prevalent challenge is equipment wear and tear. Over 30% of mills experience decreased efficiency due to unaddressed wear in their rollers. Regular inspection and maintenance are essential. Components like bearings and rolls may need replacement after only 10,000 hours of operation. Ignoring these signs can lead to unexpected shutdowns and increased costs.

Moreover, incorrect setup can lead to bad material flow. This mistake can often be overlooked, causing significant production losses. For instance, a misalignment of just 1mm can affect rolling output by up to 15%. Operators must ensure proper alignment and calibration to avoid these pitfalls. Attention to these details can substantially enhance operation efficiency and product quality.

Related Posts

-

2026 Best Hot Rolling Mill Machine Insights and Innovations?

-

Top Rolling Mill Machine Types for Industrial Applications?

-

Top 10 Cut to Length Line Machines for Efficient Manufacturing Solutions?

-

Top Coil Rolling Machine Features and Benefits for Your Production Line?

-

Top 10 Benefits of Using Stainless Steel Slitting Machines for Your Business

-

2026 How to Use a Tube Straightening Machine Effectively?