Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

In the manufacturing industry, the efficient use of machinery can significantly impact production timelines and cost-effectiveness. As noted by industry expert James Anderson, a renowned mechanical engineer specializing in metal fabrication, "Maximizing the capabilities of a sheet coil cutting machine not only enhances productivity but also ensures precise material utilization." His insights highlight the importance of understanding and mastering the intricacies of these cutting machines, which are essential for businesses looking to streamline operations.

Sheet coil cutting machines are pivotal in converting raw coil materials into manageable and accurately sized sheets for various applications. However, many companies overlook the potential of these machines due to a lack of proper training and operational knowledge. By implementing effective strategies, operators can unlock the full potential of their equipment, resulting in improved throughput and reduced waste.

This article will delve into the ultimate tips for the efficient use of sheet coil cutting machines, aiming to provide operators and manufacturers with valuable insights that can lead to enhanced performance and lower operational costs. By embracing best practices in machine setup, maintenance, and operation, businesses can not only improve their productivity but also gain a competitive edge in the market.

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

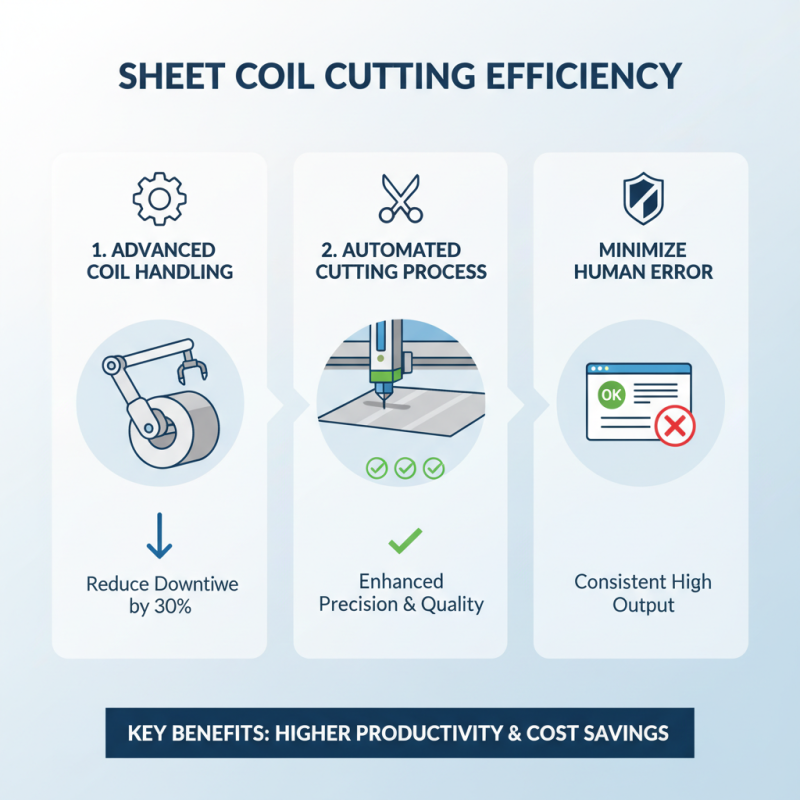

When it comes to the efficient use of sheet coil cutting machines, understanding the technology and maximizing operational strategies is essential. Industry reports indicate that utilizing advanced coil handling systems can reduce downtime by up to 30%, significantly enhancing productivity. Incorporating automation into the cutting process not only ensures precision but also minimizes human error, which is critical in maintaining high-quality output.

Moreover, regular maintenance and calibration of the cutting machines play a pivotal role in their efficiency. According to data from the Metal Forming Association, companies that implement routine maintenance programs see a 15% increase in machinery lifespan while reducing unexpected breakdowns by up to 20%. Training operators on best practices, including the proper setup and adjustment of cutting parameters based on material thickness and type, can lead to a smoother workflow and reduced scrap rates. By focusing on these primary areas, sheet coil cutting operations can achieve optimal performance and cost-effectiveness.

Understanding Sheet Coil Cutting Machine Specifications and Types

When selecting a sheet coil cutting machine, it is essential to understand the various specifications that differentiate models and their functions. Different machines come equipped with features such as cutting width, speed, and the type of cutting mechanism they employ—be it shearing, rotary, or laser cutting. Each method has its advantages, with rotary cutters often being chosen for their precision on thinner materials, while shearing machines are ideal for thicker substrates.

Additionally, it's important to recognize the types of sheet coil cutting machines available in the market. These can range from manual to fully automated systems, with automatic machines generally offering higher efficiency and reduced labor costs. Understanding the material compatibility is also crucial, as some machines are designed specifically for metal, plastic, or composites. By carefully examining these specifications and types, operators can make informed decisions that align with their production needs, thereby maximizing efficiency and output.

Key Maintenance Practices for Enhanced Machine Performance

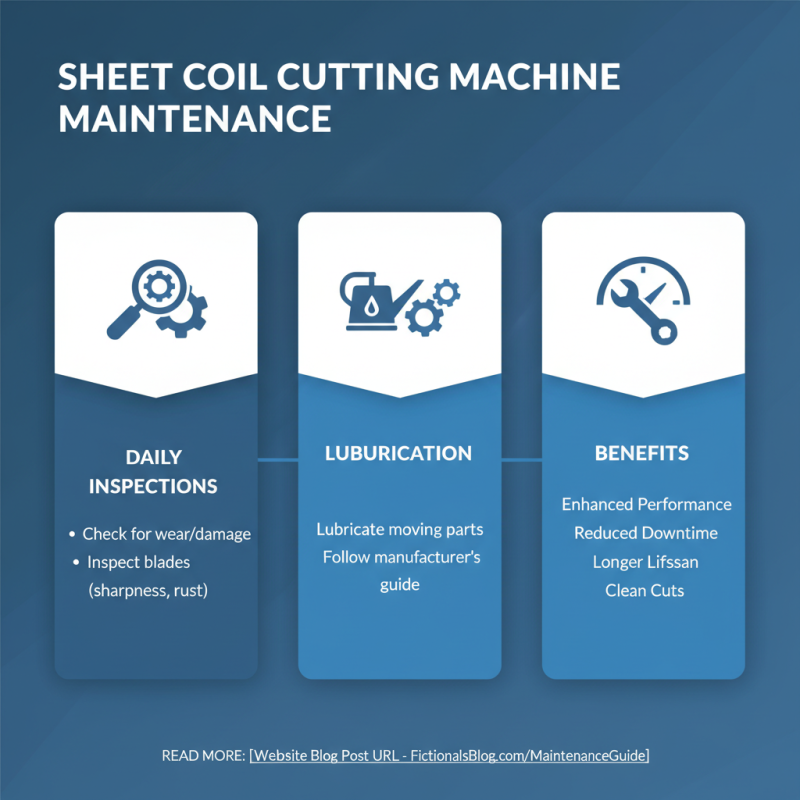

To ensure enhanced performance of sheet coil cutting machines, regular maintenance practices are crucial. First and foremost, operators should conduct daily inspections to identify any wear or damage to the machine components. Checking the blades for sharpness and any signs of rust can prevent unnecessary downtime and ensure clean cuts. Additionally, lubricating moving parts as per the manufacturer’s guidelines helps in reducing friction and prolonging the life of the machine.

Another important aspect of maintenance involves keeping the machine clean and free from debris. Regularly removing metal shavings and dust not only maintains the visual appeal of the equipment but also prevents potential blockages and overheating during operation. Furthermore, investing in a comprehensive maintenance schedule that includes periodic professional servicing ensures that the machine operates at peak efficiency. This proactive approach not only enhances performance but can also significantly reduce repair costs and extend the longevity of the equipment.

Optimizing Material Setup for Improved Cutting Efficiency

Optimizing material setup is crucial for enhancing the efficiency of sheet coil cutting machines. One key aspect is ensuring precise alignment of cutting tools with materials, which can significantly impact cutting precision and speed.

Recent advancements in laser technology, particularly with CO2 lasers, highlight how improved integration of laser systems can refine this alignment. The use of real-time optimization control in laser-assisted cutting processes can further enhance efficiency by dynamically adjusting parameters to minimize environmental impact while maintaining high productive rates.

Additionally, innovative approaches to multi-objective optimization emphasize the importance of adjusting cutting parameters and tool geometries based on material characteristics. For instance, studies show that employing specific lubrication techniques during machining can alter the performance of superalloys like Monel 400, enhancing their machinability. By focusing on continuous improvements and integrating various techniques, such as those derived from finite element simulations, manufacturers can achieve substantial gains in both cutting efficiency and quality.

Analyzing Cutting Parameters to Reduce Waste and Increase Precision

Efficient utilization of sheet coil cutting machines hinges on precise cutting parameters that directly impact operational efficiency and resource management. By analyzing factors such as cutting speed, feed rate, and blade angle, manufacturers can significantly reduce material waste while enhancing overall precision.

Optimizing these parameters not only improves the final product quality but also contributes to a more sustainable production process, minimizing the environmental footprint associated with excessive waste.

Additionally, integrating innovative technologies, such as AI, can further refine the cutting process. AI-driven systems enable real-time monitoring and adjustments, ensuring that cutting parameters are consistently optimized for each job.

This adaptability allows for quick responses to changes in material properties or design specifications, ultimately leading to greater operational efficiency. The convergence of advanced cutting techniques and intelligent forecasting tools promises a more streamlined approach to manufacturing, driving both productivity and sustainability in the industry.

Conclusion

The article "Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines" provides valuable insights into optimizing the performance and efficiency of sheet coil cutting machines. It begins by detailing the various specifications and types of these machines, helping users understand which equipment best suits their needs. Key maintenance practices are highlighted to ensure enhanced performance, which is crucial for maintaining productivity.

Furthermore, the article emphasizes the importance of optimizing material setup and analyzing cutting parameters to minimize waste and increase precision in cutting operations. Safety protocols are also discussed to ensure a secure working environment during the operation of sheet coil cutting machines. Collectively, these tips aim to improve cutting efficiency and operational safety, making it a comprehensive guide for users in the industry.

Related Posts

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today