Coil Cut to Length Machine Tips for Optimal Performance?

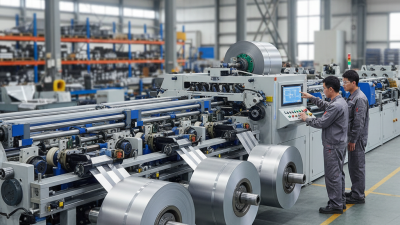

In the fast-paced world of manufacturing, the coil cut to length machine plays a crucial role. Expert John Smith states, "Precision in cutting can make or break efficiency." This insight reflects the importance of optimal performance in these machines.

Operators often face challenges when setting up and maintaining their coil cut to length machine. Issues can arise from misalignment or improper calibration. These mistakes can lead to wasted materials and increased costs. Attention to detail is vital for success.

Moreover, regular maintenance is key. Neglecting this can result in equipment malfunction. Operators should be trained to spot early signs of wear. Learning from past mistakes can enhance productivity and reduce downtime. The need for a thoughtful approach is essential in mastering the coil cut to length machine.

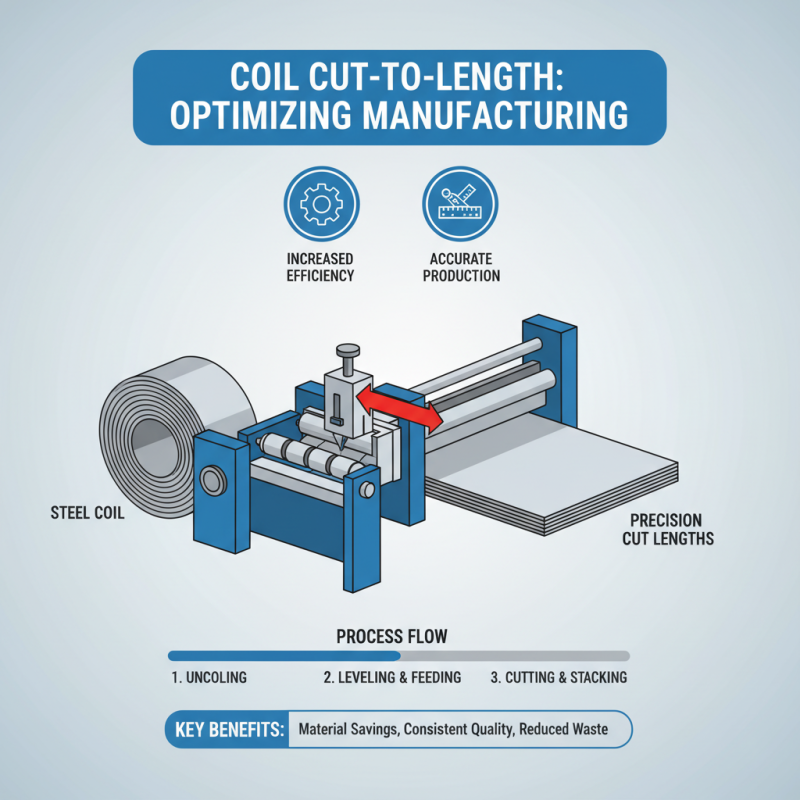

Coil Cut to Length Machine Overview and Functionality

Coil cut to length machines are essential in various manufacturing sectors. They accurately cut coils into defined lengths. This process is crucial for producing standard parts consistently. A well-functioning machine can significantly improve operational efficiency. However, many operators do not fully understand its functionality.

The machine typically includes a feeding system, cutting apparatus, and control panel. The feeding system ensures the coil is unwound smoothly. If it jams, production can slow dramatically. Adjusting the tension is vital. A loose coil can lead to poor cuts. Conversely, if it's too tight, it can cause damage.

Regular maintenance is often overlooked. This can cause various issues, such as uneven cuts or machine failure. It's advisable to inspect blades for wear frequently. Operators should ensure the settings match the material specifications. Even minor errors can lead to wasted materials. Listening for unusual sounds during operation can also indicate problems.

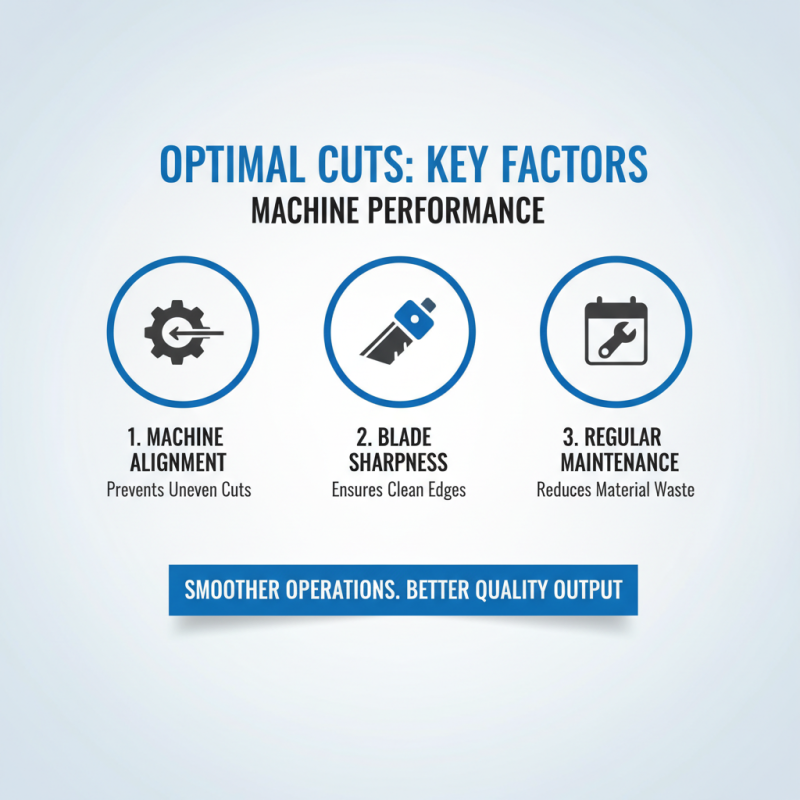

Key Factors Affecting Coil Cut to Length Machine Performance

When considering the performance of coil cut to length machines, several key factors come into play. Machine alignment is crucial. Misalignment can lead to uneven cuts. Regular checks ensure that the cutting blades are correctly positioned. Blade sharpness is another vital aspect. Dull blades can cause jagged edges. This not only affects appearance but can also lead to material waste.

Another significant factor is the speed of operation. While speed may improve efficiency, it can compromise accuracy. Operators should monitor the speed closely. Adjustments may be necessary based on material type. Additionally, training for staff is important. A well-trained operator can identify problems early. They can also adapt to changes in production needs.

Lastly, maintenance cannot be overlooked. A well-maintained machine runs smoother and cuts cleaner. Neglect can lead to more significant issues down the line. Operators should establish a routine for inspections. Attention to these details might seem trivial but can yield significant benefits. Each element plays a role in the overall effectiveness of the coil cut to length process.

Maintenance Practices for Optimal Machine Efficiency

Proper maintenance of coil cut to length machines is crucial for achieving optimal efficiency. According to industry reports, machines that adhere to a regular maintenance schedule can boost productivity by up to 15%. Keeping components clean ensures consistent performance. Dust and debris can lead to unexpected breakdowns. A clean machine operates more smoothly, reducing wear and tear on parts.

Routine inspections are essential. Operators should check for wear on blades and bearings. Inspection studies show that replacing worn parts before failure can save up to 30% on repair costs. It may seem tedious, but investing time in these checks prevents larger issues. Some operators neglect this step, leading to increased downtime and costs.

Lubrication also plays a key role. Regularly lubricated machines run more efficiently. Industry standards recommend lubrication after every shift. This is not always feasible. Some operators delay, thinking it won't impact performance immediately. But over time, neglecting this can lead to significant damage. Data suggests that improper lubrication increases maintenance costs by around 25%. This fact highlights the importance of sticking to a solid maintenance routine.

Coil Cut to Length Machine Tips for Optimal Performance

| Maintenance Practice | Description | Frequency | Impact on Efficiency |

|---|---|---|---|

| Lubrication | Regularly lubricate moving parts to reduce friction and wear. | Weekly | Improves machine longevity and reduces downtime. |

| Blade Inspection | Check blades for dullness and replace as necessary. | Monthly | Ensures clean cuts and reduces scrap material. |

| Calibration | Regularly calibrate machine settings for precision cutting. | Quarterly | Maintains product quality and reduces rework. |

| Cleanliness | Keep the machine and surrounding area clean to prevent contamination. | Daily | Reduces the risk of malfunctions and ensures smooth operation. |

| Operator Training | Ensure operators are properly trained on machine use and safety. | Annually | Improves the safe and effective use of the machine. |

Common Issues and Troubleshooting Techniques

When dealing with coil cut to length machines, issues can arise that may affect performance. A common problem is jagged cuts. This can result from dull blades or improper alignment. Regularly check the blades and perform maintenance. Adjusting the blade height can also improve the cut quality.

Another frequent issue is inconsistent feed rates. This might lead to uneven lengths of material. Ensure that the material is properly loaded and the rollers are functioning well. Monitoring the material for bends or kinks is crucial as they can disrupt the feed process.

Tips: Always keep spare parts ready, like blades and belts. This ensures you can quickly address issues. Document any recurring problems for analysis. Engage your team in troubleshooting conversations; sometimes, fresh eyes can spot a simple solution. Regular training can also enhance your team's ability to manage minor issues efficiently.

Best Practices for Material Handling and Setup

When handling materials for a coil cut to length machine, organization is key. Ensure your workspace is tidy. Store materials securely to prevent damage. It’s common to overlook this step in the rush to start production. Laying out materials properly can save time and reduce errors later.

Setup is another crucial factor. Check your machine’s specifications and adjust settings before beginning. Calibration is vital. Sometimes, machines can be a bit off. This can lead to waste and misalignment. Take a moment to reflect on adjustments needed for optimal performance. Rushing through setup might seem efficient, but it often leads to more problems down the line.

Handling and setup go hand-in-hand. Workers might forget safety protocols while focusing on speed. Clear procedures help minimize risks. Regular training can improve operator confidence. This creates a safer, more efficient environment. Every small detail contributes to overall productivity. Missing even one step can cause delays and frustration.

Coil Cut to Length Machine Performance Metrics

This chart illustrates the optimal performance metrics for coil cut to length machines, focusing on the efficiency of various setups in material handling.

Related Posts

-

How to Choose the Right Coil Cutting Machine for Your Business Needs

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

What is a Sheet Metal Slitting Machine and How Does It Work?

-

Why You Should Choose a Machine Slitter for Your Cutting Needs