How to Choose the Right Coil Cutting Machine for Your Business Needs

Choosing the right coil cutting machine for your business is a critical decision that can significantly impact your production efficiency and profitability. According to a recent industry report from the International Association of Manufacturers, the global demand for coil cutting machines is expected to grow by 8% annually, reflecting the increasing need for precision in various manufacturing processes. This trend highlights the importance of understanding the unique requirements of your operations before making an investment.

Industry expert Dr. John Smith, a leading authority in manufacturing technologies, emphasizes the significance of selecting the appropriate equipment. He states, “Investing in the right coil cutting machine can streamline production and reduce waste, ultimately leading to enhanced operational performance.” As businesses navigate the complexities of modern manufacturing, the choice of a coil cutting machine can determine their competitive edge in the market. This overview aims to provide insights into the essential factors that should guide your decision-making process for this vital piece of equipment.

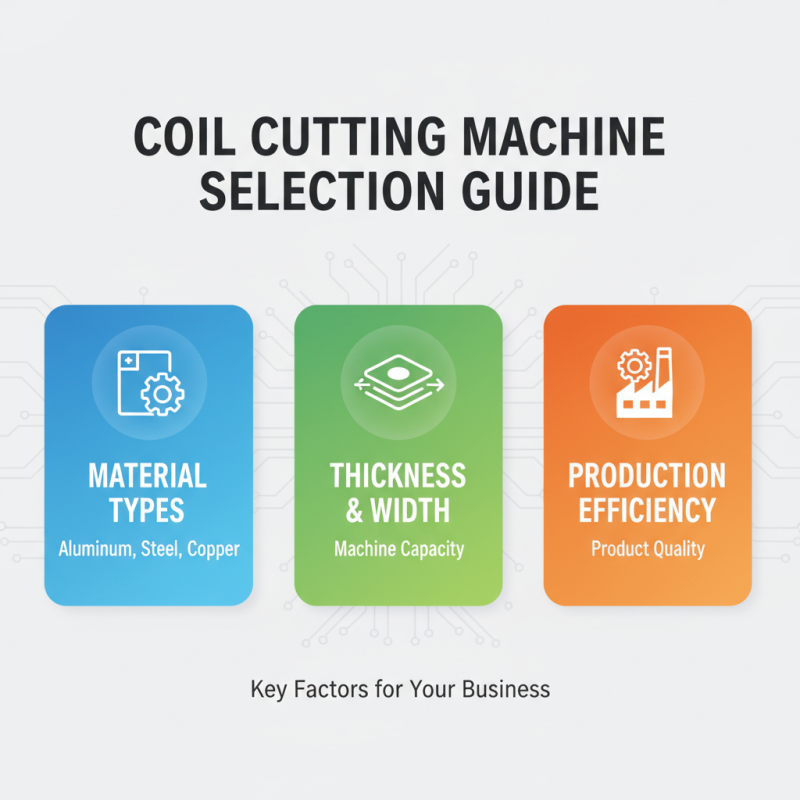

Factors to Consider When Choosing a Coil Cutting Machine

When selecting a coil cutting machine for your business, it's essential to consider several key factors that can significantly impact production efficiency and product quality. First, assess the material types you will be working with. Different machines are designed to handle various materials, such as aluminum, steel, or copper, and understanding the specific requirements of your materials can help you choose a suitable model. Additionally, consider the thickness and width of the coils you need to cut, as this will determine the machine's capacity and size.

Another important factor is the machine's cutting precision and speed. High precision is crucial for meeting quality standards, while cutting speed affects overall productivity. Look for machines that offer adjustable speed settings and advanced cutting technologies to ensure versatility. Furthermore, evaluate the machine's ease of use and maintenance requirements. User-friendly interfaces and straightforward maintenance processes can reduce downtime and enhance operational efficiency. By weighing these factors carefully, you can make an informed decision that aligns with your business’s specific needs and goals.

Types of Coil Cutting Machines and Their Applications

When selecting a coil cutting machine, understanding the various types available and their specific applications is crucial for optimizing production efficiency. The most common types of coil cutting machines include shearing machines, slitting machines, and blanking machines. According to a market report by Allied Market Research, the global sheet metal processing equipment market, which encompasses coil cutting machines, is expected to grow significantly, reaching over $9 billion by 2026. This growth is driven primarily by the increasing demand for customized metal products in industries such as automotive, construction, and manufacturing.

Shearing machines are ideal for straight cuts and are widely used in both small-scale operations and large manufacturing settings. They are known for their precision and efficiency, making them suitable for high-volume tasks. On the other hand, slitting machines are designed to cut coils into narrower strips, which is essential in industries looking to create different sizes of metal sheets from larger rolls. A report by Grand View Research states that the global coil processing market will see a compound annual growth rate (CAGR) of 4.2% from 2021 to 2028, underscoring the importance of selecting the right cutting machine for operational needs.

Blanking machines serve a slightly different purpose, being used to cut out shapes and components from coils, making them indispensable in industries that require intricate designs. With the rise in automation and advanced manufacturing techniques, businesses must consider not only the machine type but also features such as ease of use, maintenance requirements, and integration with existing production lines. Taking these factors into account ensures that companies can maximize productivity while meeting the specific needs of their markets.

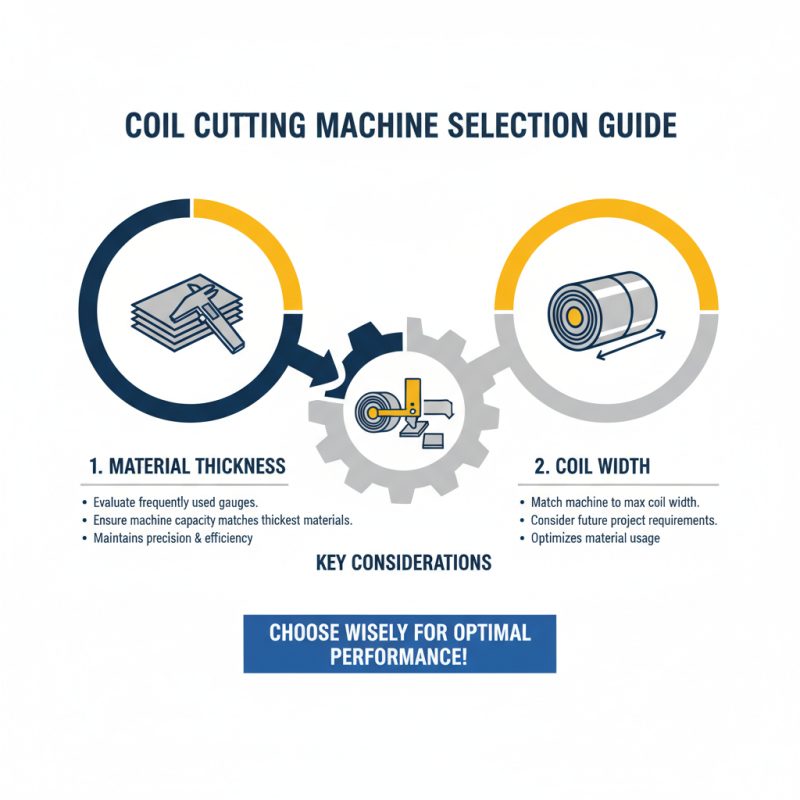

Understanding Material Thickness and Coil Width Specifications

When selecting a coil cutting machine for your business, understanding material thickness and coil width specifications is crucial. Different projects may require varying thicknesses, and it is essential to choose a machine that can accommodate your specific material needs. For instance, if you frequently work with thicker materials, ensure the machine's cutting capacity is capable of handling those without compromising on precision or efficiency. Evaluating the gauge of materials typically used in your operations will help narrow down your options.

Tip: Always refer to the machine's technical specifications to confirm its compatibility with your materials. This should include not just the thickness but also the maximum and minimum coil width it can handle. Investing in a versatile machine that can adapt to various widths will save you time and costs in the long run.

Additionally, keep in mind that the coil width directly affects the usability of the machine. A wider coil can increase production efficiency but may require more storage space and can impact the machine's overall footprint. Choose a cutting machine that balances efficiency with the practicalities of your workspace.

Tip: Assess your production volume and space constraints before making a decision. A thorough understanding of your material requirements and workspace will lead to more informed choices, ultimately enhancing your operational workflow.

Evaluating Machine Speed and Production Capacity Requirements

When selecting a coil cutting machine, evaluating machine speed and production capacity is crucial for maximizing efficiency and meeting business demands. The speed of the machine directly impacts how quickly you can produce finished goods. A higher speed often translates to greater output, but it’s essential to consider whether that speed aligns with your production goals. For businesses with high volume needs, investing in a machine capable of sustaining a fast cutting speed can significantly enhance productivity.

Tips: Before deciding, assess your average production goals. Calculate how many units you need to produce daily, weekly, and monthly. This assessment will provide a clear picture of the minimum speed and capacity the machine should offer to avoid delays and meet customer expectations.

When evaluating production capacity, it's vital to consider not only the machine's maximum output but also the material handling capabilities and operational efficiency. A machine that can handle various coil sizes and weights might offer more flexibility and adaptability as your business evolves. Understanding the types of materials you work with will also ensure that the machine you choose can handle the specific demands of your production line.

Tips: Conduct a thorough analysis of your current and projected workload. Look for machines that can scale with your production needs, ensuring you’re not left with a machine that’s underperforming or one that becomes obsolete as your business grows.

How to Choose the Right Coil Cutting Machine for Your Business Needs

| Machine Model | Cutting Speed (m/min) | Production Capacity (tons/day) | Material Compatibility | Control System |

|---|---|---|---|---|

| Model A | 50 | 10 | Steel, Aluminum | PLC |

| Model B | 40 | 8 | Copper, Brass | Touchscreen |

| Model C | 30 | 5 | Plastic, Foam | Manual |

| Model D | 60 | 12 | Steel, Plastic | Automated |

Assessing Budget and Cost-Efficiency of Coil Cutting Solutions

When choosing a coil cutting machine for your business, assessing budget and cost-efficiency is paramount. Industry reports indicate that the capital investment in coil cutting equipment can vary significantly, with entry-level machines priced around $10,000 to $30,000, while high-end models may exceed $100,000. The total cost of ownership also includes maintenance, training, and operational costs, which can accumulate over time. Understanding the full financial impact will help ensure your investment not only suits your immediate needs but also provides long-term value.

Tips for evaluating cost-efficiency include conducting a thorough breakdown of projected expenses versus anticipated savings. A recent market analysis suggests that companies can reduce material waste by up to 15% with advanced coil cutting technologies. Additionally, consider the machine’s versatility; a multi-functional device, while potentially bearing a higher upfront cost, can save you money in the long run by eliminating the need for additional equipment. Engaging with other businesses to gauge their experiences can also provide invaluable insights into which machines maximize cost-effectiveness while meeting production demands.

Cost Efficiency of Different Coil Cutting Machines

Related Posts

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

2025 How to Optimize Your Production with KUKA Machines Efficiently

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs