How to Choose the Right Sheet Slitting Machine for Your Business?

In today's competitive manufacturing landscape, selecting the right sheet slitting machine is crucial. According to the 2022 report by Market Research Future, the global sheet slitting machine market is expected to reach $1.5 billion by 2027, highlighting its growing importance in various industries. However, businesses often overlook essential factors during the selection process.

Expert John Smith, a leading authority in slitting technology, emphasizes, "Selecting the right machine can make or break a production line." The wrong choice could lead to inefficiencies, waste, and unsatisfactory product quality. Manufacturers must consider factors like material type, thickness, and required precision. Many businesses underestimate how these elements can impact overall operations.

It's also worth noting that not all machines are created equal. Some may offer advanced features but come with a higher price tag. Balancing cost and functionality is a common challenge. Every business should reflect on its specific needs before making a decision. Ultimately, the right sheet slitting machine can enhance productivity and drive success.

Understanding Sheet Slitting Machines and Their Applications

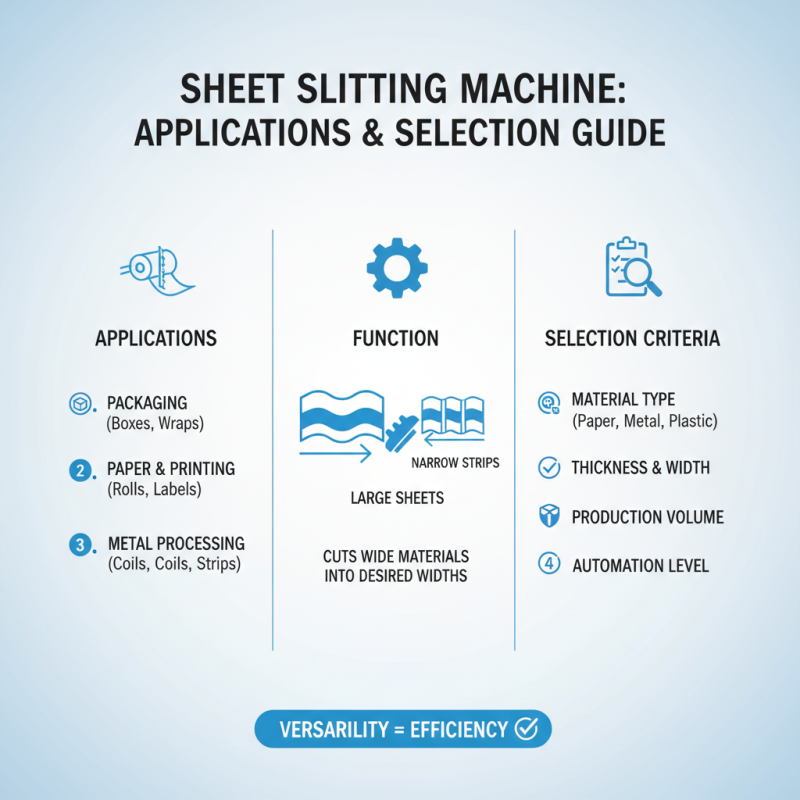

When selecting a sheet slitting machine, understanding its applications is crucial. These machines are designed to cut large sheets into narrower strips. Industries such as packaging, paper, and metal processing often rely on this technology. The versatility of slitting machines makes them invaluable. However, choosing the right one can be challenging.

Sheet slitting machines come in various types. Some are suited for thin materials, while others handle thicker stock. Consider the materials you'll be cutting. For instance, metallic sheets require machines equipped for heavy-duty tasks. Additionally, speed and precision matter. A machine that operates too slowly can hinder productivity. It's important to reflect on your business needs and choose accordingly.

Different machines offer varying features. Some have advanced controls for precise measurements. Others may lack these essential tools, causing potential issues. Evaluate your production volume. High-output facilities need robust machines to keep up. Think about maintenance as well. A complex machine may require frequent checks, complicating operations. Scrutinizing these factors will help in making a better choice.

Factors to Consider When Selecting a Sheet Slitting Machine

Choosing the right sheet slitting machine can significantly impact production efficiency. Several key factors must be contemplated during selection. Consider the material types you will process. Different machines handle various thicknesses and materials. This specificity can greatly affect output quality.

Tips: Always assess the machine’s compatibility with your materials. Testing samples could provide clarity. Look into the maximum slitting width and length limitations. Your production needs should align with these dimensions.

Another vital aspect is the machine’s speed and technology. A high-speed unit can boost productivity. However, faster speeds may lead to more errors if not monitored. Ensure the machine has advanced features like precision controls. These features can enhance quality but may complicate operation.

Tips: It's beneficial to seek user feedback on performance. Real-world experience often reveals insights beyond specifications. Maintenance requirements also deserve attention. Machines requiring frequent service can impact your workflow. A balance between automation and manual control is key here.

Key Features to Look for in a Sheet Slitting Machine

When choosing a sheet slitting machine, several key features are crucial for effective operations. The machine's cutting precision plays a vital role in product quality. A machine that can handle diverse materials and thicknesses adds versatility. Look for a reliable alignment and tensioning system to minimize waste. A robust build ensures longevity and withstands continuous use.

Tips: Always check specifications. Consider the thickness range and material types. This can save time and increase productivity.

User-friendly controls enhance efficiency. A touchscreen interface may ease operation and monitoring. Don't overlook maintenance requirements. Machines with easy access for repairs can save downtime. Additionally, pay attention to safety features. Emergency stops and safety guards can prevent workplace accidents.

Tips: Review user feedback. It helps understand long-term performance and potential issues.

Selecting the right slitting machine requires thoughtful consideration. Think about your specific production needs and future growth. The right fit can make a difference in operational success and efficiency.

Comparing Different Types of Sheet Slitting Machines

When it comes to choosing sheet slitting machines, understanding the different types is crucial. There are mainly two categories: rotary and shear slitting machines. Rotary machines utilize circular blades. They are suitable for high-speed operations. They often deliver cleaner cuts and are efficient for thin materials. However, they can be more complex to maintain.

On the other hand, shear slitting machines use a pair of blades that cross each other. They offer versatility and are ideal for thicker materials. The cuts may not always be as clean as rotary, but they are less likely to produce burrs. Each type has its pros and cons. What works for one business may not suit another. For example, rotary machines might be too fast for smaller operations. Yet, they enhance productivity when the scale is larger.

Choosing the right machine also depends on your material types. The thickness, composition, and size of sheets come into play. Think about your production goals. You may need a machine that is easily adjustable. Flexibility can be key in a fast-changing market. Take time to reflect on your specific needs. Understanding these factors can prevent costly mistakes.

How to Choose the Right Sheet Slitting Machine for Your Business?

This chart compares the average efficiency of different types of sheet slitting machines, helping you to easily identify which type may best fit your business needs based on productivity.

Evaluating Your Business Needs Before Making a Purchase

When evaluating your business needs for a sheet slitting machine, it is crucial to define your production goals. Consider your current output requirements. How many sheets do you process daily? What is the desired thickness? Understanding your capacity will help narrow down your choices. It’s not just about speed; precision matters too. A machine that cannot maintain consistent quality may not meet your needs.

Think about the materials you typically work with. Are they standard or unique? Some machines excel with specific materials but falter with others. Evaluate the flexibility of your options. Can the machine accommodate different widths and thicknesses? Moreover, consider future trends in your industry. Will your needs change? Investing in a machine that adapts to market changes can be more beneficial than a one-size-fits-all approach.

Lastly, competitor analysis is vital. Research what machines others in your industry are using. Are they satisfied? Some businesses regret their choices after purchase. Common pitfalls include underestimating maintenance costs or complexity. Dig deeper into user experiences. Always question if the machine aligns with the evolving demands of your business. Balancing cost, efficiency, and flexibility is not easy, but it is necessary.

How to Choose the Right Sheet Slitting Machine for Your Business?

| Feature | Description | Importance Level |

|---|---|---|

| Max Slitting Width | The maximum width of the material that can be slit. | High |

| Min Slitting Width | The minimum width that the machine can effectively slit. | Medium |

| Material Type | Different machines are optimized for various materials (e.g., paper, plastic, metal). | High |

| Knife Type | Options for rotary, straight, or shear knives can impact cutting performance. | Medium |

| Automation Level | Higher automation may increase efficiency but also costs. | High |

| Production Speed | Speed of slitting impacts overall production capacity. | High |

| Setup Time | Time required to set up the machine for different tasks. | Medium |

| Space Requirements | The physical space required for the machine and operations. | Medium |

| Cost of Maintenance | Ongoing costs for maintenance and parts replacement. | High |

Related Posts

-

Top Benefits of Using a Metal Coil Slitting Machine in Manufacturing Industry?

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

-

Why Choose a Stainless Steel Slitting Machine for Your Manufacturing Needs?