How to Choose the Right Sheet Coil Cutting Machine for Your Business?

Choosing the right sheet coil cutting machine is crucial for enhancing operational efficiency. According to industry reports, 79% of manufacturers prioritize precision machinery. A reliable sheet coil cutting machine ensures accurate cuts, which translates to reduced waste and cost savings. Notably, the coil processing market is projected to reach $5 billion by 2027, showcasing the increasing demand for effective equipment.

Investing in the correct machine can impact production outcomes significantly. A poorly chosen sheet coil cutting machine can lead to increased downtime and maintenance costs. Research indicates that businesses that select their machinery carefully see a 30% increase in productivity. However, the selection process isn’t straightforward. Many companies often overlook specific requirements, leading to inefficient operations.

Understanding your unique needs is essential. Each business has different specifications based on material types and production volumes. Evaluating options based on these factors can be challenging but necessary. Sometimes, it's important to reflect on past equipment failures to make informed choices in the future. This diligence will help in pinpointing the right sheet coil cutting machine that aligns with your operational goals.

Choosing the Right Sheet Coil Cutting Machine: Key Considerations

Choosing the right sheet coil cutting machine is crucial for your business efficiency. You need to consider several factors before making a decision. The machine should match the type of material you plan to cut. Different materials, like aluminum or stainless steel, require specific cutting capabilities. Check the thickness and width of the materials. Make sure the machine can handle these specifications without strain.

Another important aspect is the machine's speed and productivity. Slower machines can cause delays, affecting your overall workflow. Look for models that offer efficient cutting speeds while maintaining precision. It's essential to balance speed with quality. A machine that is too fast might compromise the cut's accuracy.

Consider your future needs as well. Investing in a machine that meets your current requirements is wise. However, think about potential growth. Will the machine adapt to increased demand? It's worth reflecting on these points. Ensure the machine aligns with your long-term goals. Many businesses overlook this, leading to costly upgrades later.

Understanding Different Types of Sheet Coil Cutting Machines on the Market

When exploring sheet coil cutting machines, understanding the various types available is essential for making the right choice. There are several types on the market. Some are manual, while others are fully automatic. Manual machines require more operator input, which might slow down production. Automatic machines offer speed and efficiency, but they come at a higher initial cost.

A key consideration is the type of material you will be cutting. Some machines handle metals, while others work better with plastics or composites. It is crucial to evaluate your specific needs. Consider the thickness and size of your materials. Not all machines can accommodate larger coils. Researching the capabilities of different machines can save hassles down the road.

Tips: Always assess your production volume. High-volume operations may benefit from automated solutions. For smaller tasks, a manual cutter might suffice. Don’t forget to evaluate maintenance requirements, too. Some machines need regular servicing to operate effectively, while others are more low-maintenance. Think about the long-term costs before making a decision. Evaluate your workspace, as some machines require more room than others.

Assessing the Production Capacity and Efficiency Requirements for Your Business

When selecting a sheet coil cutting machine, assessing production capacity is crucial. Industry reports indicate that businesses with cutting volumes of over 10 tons per day require machines capable of higher output. Efficiency matters, and machines that can process sheets at speeds of 20 meters per minute typically provide better throughput. However, speed isn't everything; the quality of cut must also be considered.

Understanding your specific operational needs is essential. For example, if your business focuses on thin gauge materials, a machine optimized for precision cutting is needed more than sheer speed. A report from the Metalworking Association shows that companies investing in high-precision machines see a 25% increase in production quality. Balancing cost with these requirements can be challenging. Some machines may promise high efficiency but fall short in durability, leading to frequent repairs. This could hinder overall productivity.

Moreover, considering the flexibility of a cutting machine is vital. A machine that handles various sheet sizes can adapt to changing demands. However, these versatile machines often come at a premium. Price analysis suggests that businesses spend an average of 15% more for equipment that can manage various specifications. Not all machines will be worth this investment; time spent on research is necessary to avoid costly mistakes.

Production Capacity vs Efficiency of Sheet Coil Cutting Machines

Evaluating Cost Factors: Initial Investment vs. Long-term Operational Costs

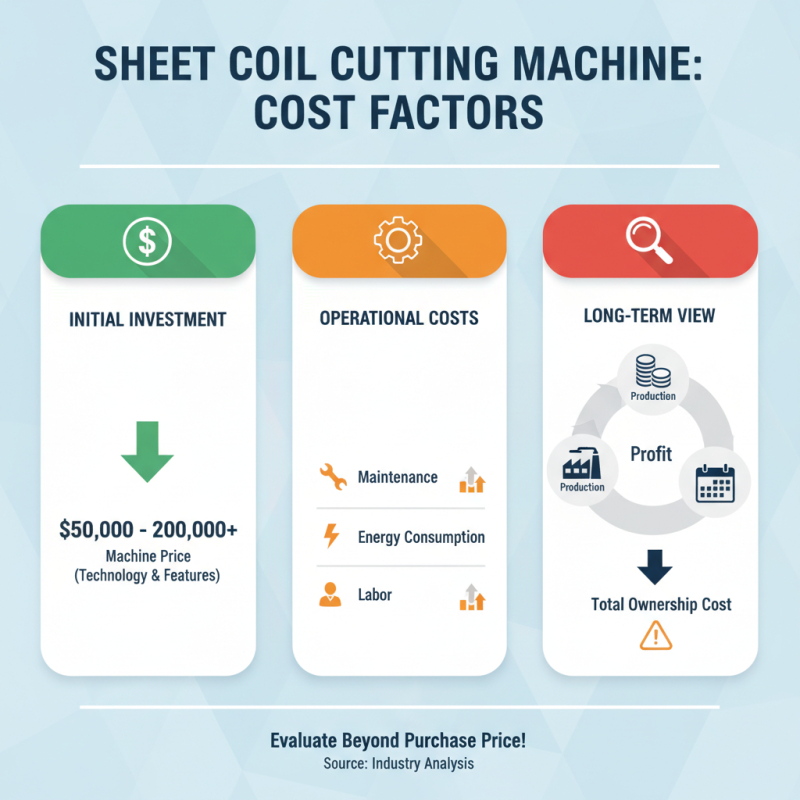

When choosing a sheet coil cutting machine, evaluating cost factors is crucial. The initial investment can be significant. Prices typically range from $50,000 to over $200,000, depending on the technology and features. However, companies often overlook the long-term operational costs associated with these machines. Maintenance, energy consumption, and labor costs add up over time.

For instance, a recent industry report highlighted that maintenance can account for up to 15% of total operational expenses annually. Regular inspections and parts replacement increase these costs. Additionally, energy usage can vary widely. Some machines have been reported to consume up to 40% more energy than their efficient counterparts.

It's also important to consider labor costs. An inefficient machine may require additional personnel to keep up with production demands. This can lead to higher wage bills. Ultimately, the total cost of ownership often surpasses the initial purchase price. It’s essential to look beyond just upfront costs and assess how operational efficiency affects your bottom line.

Importance of Machine Precision and Quality Control in Coil Cutting Processes

When choosing a sheet coil cutting machine, precision is crucial. The accuracy of cuts affects product quality. In industries like manufacturing, even minor deviations can lead to waste and increased costs. A machine that promises precision but delivers inaccuracies can disrupt operations.

Quality control should be a top priority during the coil cutting process. Regular checks can identify inconsistencies early. However, many overlook this aspect, focusing only on speed. This can backfire, resulting in faulty products. A balance between speed and quality is essential.

Investing in a reliable machine is vital for sustained success. However, the initial capital should not overshadow the long-term benefits of precision. Poor-quality cuts can damage your reputation. Reflecting on past mistakes can guide future purchases. Always prioritize quality and precision over quick fixes.

Related Posts

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Coil Cut to Length Machine Tips for Optimal Performance?

-

Why You Need a Roll Straightener Machine for Efficient Metal Processing

-

How to Choose the Right Coil Cutting Machine for Your Business Needs

-

Top 5 Pipe Straightener Machines: Best Choices for Your Workshop Needs