Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

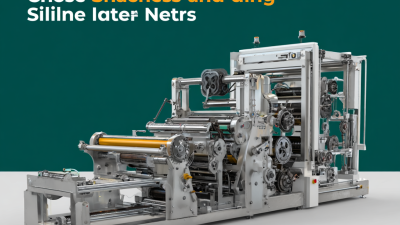

Choosing the right cold rolled slitter machine for your manufacturing needs is crucial for optimizing production efficiency and ensuring high-quality output. With numerous options available in the market, it can be daunting to navigate through various specifications, features, and technologies. This guide offers the top ten tips to consider when selecting a cold rolled slitter machine, empowering you to make informed decisions tailored to your unique requirements.

Understanding the fundamental aspects of a cold rolled slitter machine is essential for successful operation. From blade types and cutting speed to the maintenance requirements, each factor plays a vital role in the machine's performance and longevity. As we delve into these tips, we aim to equip you with the knowledge necessary to identify the best slitter machine that not only meets your production needs but also aligns with your budget and operational goals.

By keeping these crucial considerations in mind, you will be better prepared to invest in a cold rolled slitter machine that maximizes productivity, minimizes downtime, and ultimately leads to increased profitability. Let us explore these tips to help you make a confident choice in selecting the ideal slitting solution for your manufacturing processes.

Factors to Consider When Selecting a Cold Rolled Slitter Machine

When selecting a cold rolled slitter machine, several key factors must be taken into consideration to ensure optimal performance and efficiency. First, the machine's capacity is paramount; it should be able to handle the thickness and width of the materials you plan to process. Evaluate the gauge range to make sure it can accommodate various cold rolled strips, allowing flexibility in your production line.

Additionally, the slitting speed and precision are crucial elements. A faster machine may increase productivity, but it should not compromise cutting accuracy. Look for machines equipped with advanced features such as automatic tension control and synchronization systems to maintain precise slitting. Also, consider the ease of maintenance and availability of spare parts, as these will directly affect the longevity and operational efficiency of the machine. Selecting a machine with reliable support and service can save time and costs in the long run.

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

| Factor | Description | Importance Rating (1-5) |

|---|---|---|

| Material Thickness | Consider the range of material thicknesses the machine can handle for your specific applications. | 5 |

| Blade Quality | Check the durability and material used for the blades, as they affect cutting precision. | 4 |

| Speed and Efficiency | Evaluate the machine's speed to optimize production efficiency. | 5 |

| Control System | Assess the user-interface and automation features for ease of operation. | 4 |

| Size and Footprint | Measure available workspace to ensure the machine fits properly. | 3 |

| Maintenance Requirements | Consider how often the machine needs maintenance and the associated costs. | 4 |

| Cost of Ownership | Factor in initial purchase price along with operational and maintenance costs. | 5 |

| Safety Features | Look for integrated safety features to ensure operator safety during operation. | 5 |

| Supplier Support | Evaluate the manufacturer’s support services and available resources for troubleshooting. | 4 |

| Versatility | Determine if the machine can handle various materials and types of cuts. | 4 |

Understanding Different Types of Cold Rolled Slitter Machines

When it comes to selecting the best cold rolled slitter machine, understanding the

different types available on the market is crucial. Cold rolled slitter machines can typically be categorized into

two main types: the shear-type and the score-type slitter. According to the latest industry reports,

shear-type slitters are known for their efficiency in producing high-quality edge profiles, making them ideal for

materials that require precision cutting. These machines typically offer faster throughput and are best suited for

operations involving thinner materials, often achieving tolerance levels within

±0.005 inches.

On the other hand, score-type slitters utilize a scoring method that is more suitable for thicker materials,

where kerf width and edge finish are less critical. Industry data suggests that score-type slitters are particularly

popular in sectors dealing with heavy gauge materials, such as automotive

and construction, where dealing with larger coil widths and weights are common.

Additionally, the choice between these types can affect operational costs and maintenance, as shear-type machines

generally require more frequent blade changes and can incur higher running costs. Understanding these distinctions

not only aids in selecting the correct equipment but also contributes to optimizing production efficiency and

material yield in manufacturing processes.

Assessing Production Capacity and Speed Requirements

When selecting a cold rolled slitter machine, assessing production capacity and speed requirements is crucial. Understanding your production needs will help you determine the appropriate machine specifications to meet your operational goals. First, evaluate the volume of materials you plan to process daily or weekly. High-volume operations may require machines with faster processing speeds and larger coil capacities. Consider also the material thickness and width, as these factors significantly influence the efficiency of slitting operations.

Additionally, analyze the potential for future growth in production demands. A machine that meets current requirements might soon become insufficient if your business expands. Opt for a slitter with adjustable speed settings, which can accommodate varying production rates without compromising quality.

It's important to strike a balance between speed and precision, as excessive speed could lead to material defects, ultimately impacting your overall production efficiency and product quality. Taking the time to closely evaluate these aspects ensures that you select a slitter machine that not only meets current needs but also adapts to future production challenges.

Evaluating the Importance of Precision and Tolerance

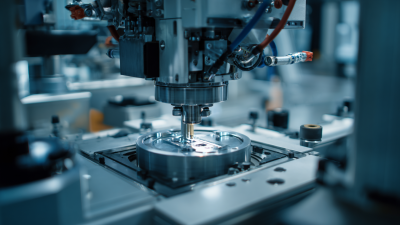

When selecting a cold rolled slitter machine, precision and tolerance should be at the forefront of your decision-making process. In industries where minute variations can lead to significant economic repercussions, it becomes imperative to ensure that the machinery operates at exact specifications. High-quality slitters not only enhance productivity but also minimize waste, thereby ensuring a better return on investment.

One of the top tips for choosing the best cold rolled slitter machine is to assess the machine's cutting accuracy. A machine that can maintain tight tolerances will ultimately result in better product quality. Additionally, consider the machine's adaptability to different materials and thicknesses, as versatility can be key in optimizing production lines.

Another essential factor is the machine's build quality and durability. Investing in a robust slitter will reduce downtime for repairs and maintenance, allowing for a smoother operation. Ensure that you evaluate the manufacturer's reputation for precision engineering, as this can be a telltale sign of the machinery's long-term performance capabilities.

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine

Budgeting: Cost Considerations for Cold Rolled Slitter Machines

When choosing the best cold rolled slitter machine, budgeting plays a pivotal role in making the right decision. The market for slitter machines can vary significantly in price, from entry-level models around $20,000 to high-end equipment exceeding $100,000. According to industry reports, investing in a high-quality slitter machine can yield a return on investment (ROI) of up to 25% annually, making it crucial to consider not just the upfront cost but the long-term implications of your purchase.

Additionally, maintenance and operational costs should not be overlooked. Experts suggest that the average annual maintenance cost for a slitter machine can range from 5% to 10% of the initial cost. Evaluating these ongoing expenses alongside your budget will ensure that you are prepared for total cost ownership. Furthermore, many manufacturers now offer financing options or leasing solutions that can ease financial stress and allow for flexible budgeting strategies, providing businesses with more accessible pathways to acquire advanced slitting technology without straining their finances.

Related Posts

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

2025 How to Optimize Your Production with KUKA Machines Efficiently