How to Choose the Best Automatic Length Cutting Machine for Your Needs?

Choosing the right automatic length cutting machine can feel overwhelming. According to industry expert John Smith, "The perfect machine should meet specific needs without breaking the bank." This sentiment resonates deeply in today's market.

An automatic length cutting machine can significantly enhance productivity. With numerous options available, understanding your unique requirements is crucial. You might need a machine for precise cuts, speed, or versatility. Each feature can impact your outcomes.

Many buyers overlook critical details. Features that seem minor can affect overall performance. You might find a machine that looks good on paper but fails in practice. Reflecting on past purchases can help you make better decisions. Consider your production needs and budget carefully before making a choice.

Understanding Automatic Length Cutting Machines and Their Importance

Automatic length cutting machines play a crucial role in various industries. They ensure precision and efficiency. These machines can handle diverse materials, including metal, plastic, and wood. The right machine can significantly affect production quality. Understanding how they work helps in making the best choice.

When selecting a cutting machine, consider your primary needs. Think about the materials you will process. Examine the thickness and size requirements. You must also assess your production volume.

Tips: Always check user reviews for insights on performance. Look for machines with adjustable settings for better flexibility. Finally, ensure the machine has reliable safety features to prevent accidents. Ignoring these aspects can lead to costly mistakes.

Key Features to Consider When Selecting an Automatic Cutting Machine

When selecting an automatic length cutting machine, several key features must be considered. Precision is crucial. For example, machines with an accuracy of ±0.5 mm are often preferred in many industries. This allows for slight variances in material types. Also, check the cutting speed. A higher speed can significantly increase production efficiency. Reports indicate that cutting machines operating above 30 meters per minute boost productivity by up to 20%.

Another essential feature is material compatibility. Not all machines can handle various materials effectively. Some are limited to metals, while others work well with plastics and textiles. Verify the machine’s specifications. Ensure it aligns with your material needs. Furthermore, consider ease of use. User-friendly interfaces can minimize training time. Complex machines may lead to operational errors and frustration.

**Tip:** Always review user feedback. Real-world performance can vary from data sheets. Look for patterns in reliability and maintenance needs. This insight can guide better decision-making.

**Tip:** Invest time in comparing different models. Even minor differences can impact daily operations. Assessing multiple options often reveals ideal configurations and potential pitfalls.

Key Features to Consider When Selecting an Automatic Cutting Machine

Assessing Your Material Types and Cutting Requirements

Choosing the right automatic length cutting machine involves understanding your material types and cutting requirements. Various materials behave differently during cutting. For instance, soft materials like foam require gentler cutting methods, while hard materials like metal need robust machines. It is vital to assess these attributes to ensure efficiency.

Consider the thickness of the materials you work with. Machines have different capacities, and exceeding these can lead to poor cuts and machine damage. Research specifications carefully. The type of cut is also crucial. Straight cuts, angled cuts, or intricate shapes necessitate different machines. Make a list of your most common projects. This will guide your selection process effectively.

Don’t overlook machine maintenance as it plays a role in performance. Some users may not recognize the importance of upkeep until it’s too late. Regular maintenance ensures the machine operates efficiently. A poorly maintained machine can lead to material waste and increased costs. Reflect on your operating environment as well. Dust and debris can affect precision. Consider how ventilation and cleanliness are maintained in your workspace.

How to Choose the Best Automatic Length Cutting Machine for Your Needs?

| Material Type | Cutting Range (mm) | Max Cutting Thickness (mm) | Feed Speed (m/min) | Precision (mm) | Suitable Industries |

|---|---|---|---|---|---|

| Aluminum | 100 - 3000 | 10 | 15 | 0.1 | Manufacturing, Aerospace |

| Steel | 200 - 5000 | 20 | 10 | 0.2 | Construction, Metalworking |

| Plastic | 50 - 2000 | 5 | 20 | 0.05 | Packaging, Automotive |

| Wood | 100 - 3000 | 30 | 12 | 0.3 | Furniture, Construction |

| Composite Materials | 100 - 1500 | 10 | 25 | 0.2 | Aerospace, High-Tech |

Evaluating Machine Specifications and Performance Metrics

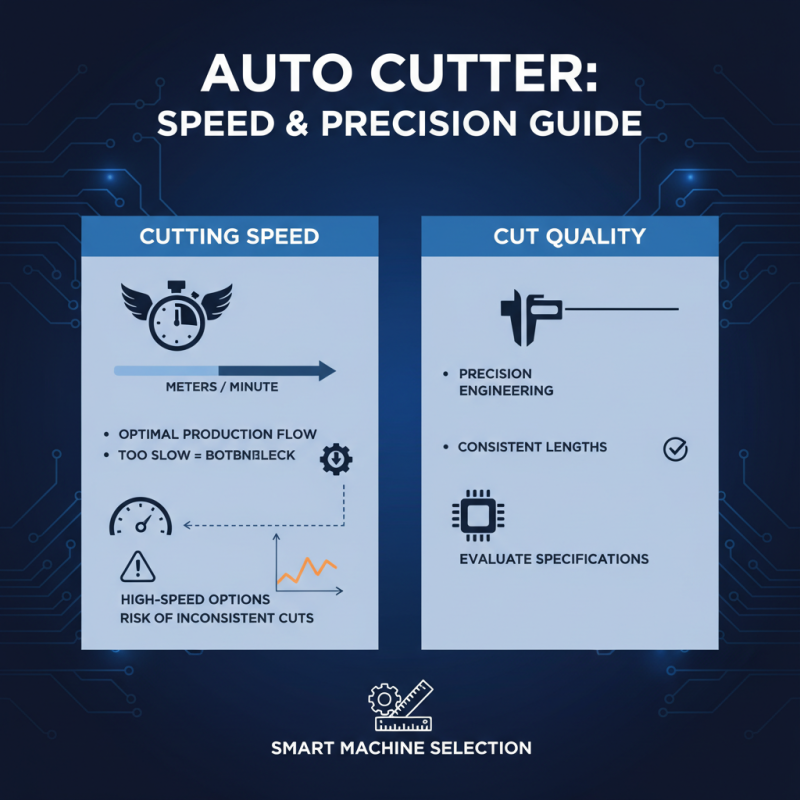

Selecting the right automatic length cutting machine requires careful evaluation of specifications and performance metrics. Start by examining the cutting speed. A machine that operates too slowly may bottleneck production. Look for rates measured in meters per minute. High-speed options are available, but they might yield inconsistent cuts if not engineered properly.

Next, consider the precision of the cuts. Specifications should detail the machine's accuracy, often represented in millimeters. Inconsistent accuracy can lead to material waste. It's crucial to balance speed and precision. A machine might excel in one area while underperforming in another. This can create challenges during operation.

Finally, assess the machine's ease of use. Operators should feel comfortable navigating its features. Complicated interfaces can lead to mistakes. Think about how easily the machine can be maintained. A machine that requires frequent servicing can disrupt workflow. Finding a balance between functionality and user experience is key to making the right choice.

Comparing Brands and Models for Optimal Value and Reliability

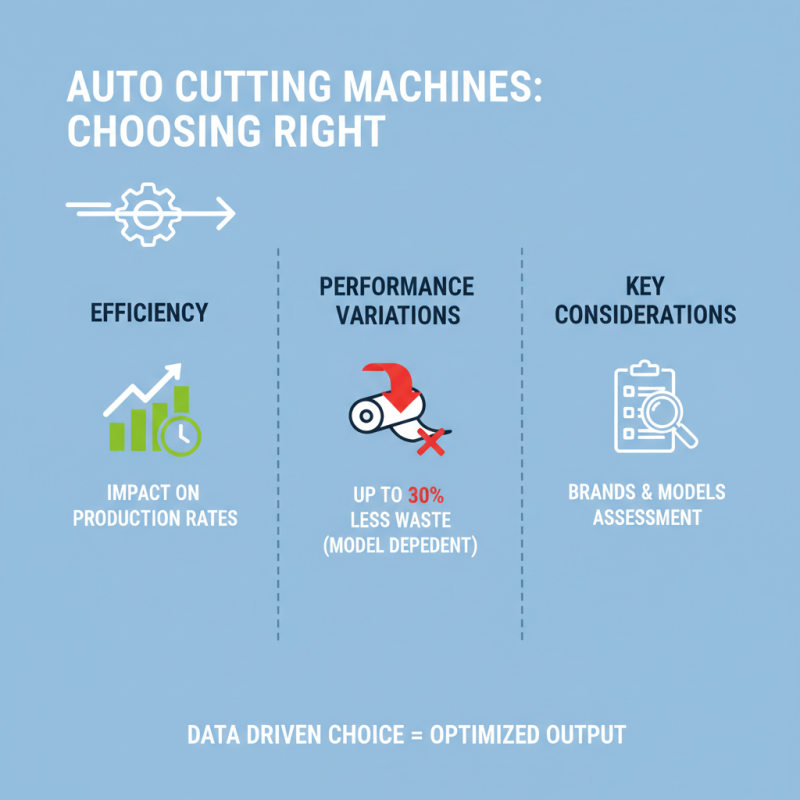

Choosing the right automatic length cutting machine requires careful consideration of various brands and models. Recent data indicates that the efficiency of these machines can significantly impact production rates. A study found that model variations can lead to performance differences of up to 30% in material waste. This highlights the importance of assessing each option thoroughly.

Brand reputation plays a crucial role in reliability. However, not all well-known brands guarantee the best value. Market research shows that lesser-known models can sometimes outperform established brands in durability and cost-effectiveness. Users often overlook these options, thinking they are inferior. This perspective proves flawed as many high-value models remain undiscovered.

Price is another factor. It’s vital to compare machines with similar features. Reports suggest that spending slightly more can lead to a 15% increase in lifespan. It’s essential to evaluate whether higher upfront costs yield significant long-term savings. Ignoring this could result in losing money over time. Many decision-makers fail to account for the total cost of ownership. This often leads to regret after the purchase.

Related Posts

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

What is a Roller Leveling Machine and How Does It Work?

-

Top Factors to Consider When Choosing a Roll Straightening Machine

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

2025 How to Optimize Your Production with KUKA Machines Efficiently