Why Choose a Stainless Steel Slitting Machine for Your Manufacturing Needs?

In today’s competitive manufacturing landscape, choosing the right equipment is crucial. The stainless steel slitting machine stands out for its efficiency and durability. According to recent industry reports, the demand for stainless steel products has risen by 12% annually. This growth emphasizes the need for advanced machinery that can meet high production standards.

The stainless steel slitting machine is designed for precision and speed. It can handle various thickness levels, making it versatile for different applications. Factories using these machines often report a 20% increase in productivity. However, machine maintenance and operational training are essential for maximizing these benefits. Without proper care, even the best machines can underperform.

Investing in a stainless steel slitting machine requires careful consideration. Each manufacturer's needs are unique. Some businesses may overlook the potential of these machines, focusing solely on cost. Yet, their long-term efficiency and reliability can lead to significant cost savings. Thus, understanding both the advantages and limitations is vital for informed decision-making.

Benefits of Using a Stainless Steel Slitting Machine

When choosing a slitting machine, stainless steel stands out. It offers durability and strength. This material resists corrosion. It withstands harsh manufacturing environments. The longevity of stainless steel means fewer replacements. This can reduce operational costs over time.

Stainless steel machines are also easier to clean. Maintenance is straightforward, ensuring high hygiene standards. This is crucial for many industries. Additionally, these machines operate quietly, creating a better workplace. A smooth operation is what many manufacturers desire.

However, stainless steel machines can require higher upfront investments. This might deter some businesses. There are pros and cons to weigh. It's important to assess specific needs and budget. In the long run, the benefits often outweigh initial challenges.

Why Choose a Stainless Steel Slitting Machine for Your Manufacturing Needs? - Benefits of Using a Stainless Steel Slitting Machine

| Feature | Description | Benefits |

|---|---|---|

| Durability | Made from high-quality stainless steel that resists corrosion and wear. | Longer lifespan and reduced maintenance costs. |

| Precision | Equipped with advanced cutting technology for accurate slitting. | Improved product quality and consistency. |

| Versatility | Can process various materials including stainless steel, aluminum, and copper. | Suitable for a wide range of manufacturing applications. |

| Efficiency | High cutting speeds with minimal downtime. | Increased production output and faster turnaround times. |

| Safety Features | Includes safety guards and emergency stop functions. | Reduced risk of accidents during operations. |

Key Features of Stainless Steel Slitting Machines

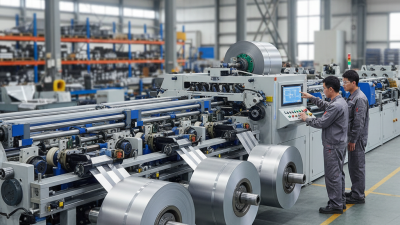

When it comes to manufacturing, choosing the right equipment is crucial. Stainless steel slitting machines have become popular for their versatility and reliability. These machines can cut various materials effectively. They are particularly beneficial for producing precise strips of stainless steel.

One key feature of stainless steel slitting machines is their adjustable cutting width. This flexibility allows manufacturers to meet specific market demands. The machines often come with advanced control systems. They help operators monitor speed and adjust settings in real-time. However, these sophisticated systems may require thorough training.

Another notable aspect is their durability. Stainless steel construction enhances the machine's lifespan, making it suitable for heavy-duty use. Still, regular maintenance is essential to prevent wear and tear. Operators should be attentive to signs of wear. Neglecting maintenance could lead to failure and costly downtime. These machines can help optimize production, but they also pose challenges that manufacturers need to address.

Comparative Analysis: Stainless Steel vs. Other Materials

When choosing materials for manufacturing, stainless steel stands out. It offers excellent durability and resistance to corrosion. Unlike aluminum, stainless steel does not dent easily. In high-pressure environments, it performs reliably. This makes it a go-to choice for various applications.

The versatility of stainless steel is unmatched. It can be used in diverse industries, from automotive to construction. Other materials, like plastic or copper, might fail under extreme conditions. They age more quickly and can affect product longevity. Stainless steel, however, maintains strength over time.

There are challenges, too. Stainless steel is heavier than alternatives. This can make transportation more complex and costly. It also requires specialized cutting tools during production. These considerations might lead some manufacturers to shy away. Reflecting on these factors is essential for making the best choice.

Applications of Stainless Steel Slitting Machines in Various Industries

Stainless steel slitting machines are essential in various industries. They efficiently process stainless steel strips into different widths and sizes. This adaptability makes them valuable in sectors such as automotive, construction, and electronics. According to industry reports, the global market for stainless steel processing is expected to reach $100 billion by 2025. This growth reflects the rising demand for high-quality stainless steel products.

In the automotive sector, slitting machines play a critical role. They produce components for vehicles, such as bumpers and frames. Precision is key here, as even a slight variation can lead to structural issues. Industry data shows that nearly 40% of automotive production relies on stainless steel. The construction industry also benefits, utilizing these machines for structural components and decorative elements. However, challenges remain, such as machine maintenance and efficiency levels.

Electronics is another field where slitting machines are crucial. They create thin metal strips for circuit boards and connectors. The need for accuracy is paramount, and any defect can lead to product failure. Despite their advantages, companies often struggle with optimizing workflows and reducing waste. Continuous refinement and investment in technology will be essential as the demand for stainless steel products rises.

Maintenance Tips for Optimal Performance of Slitting Machines

Maintaining a stainless steel slitting machine is crucial for its performance. Regular checks can prevent larger issues. Start with daily inspections. Look for any unusual vibrations or sounds during operation. These small signs can indicate underlying problems. Keeping the blades sharp is essential too. Dull blades can lead to uneven cuts and damage materials.

Lubrication is another key aspect. Properly lubricating moving parts reduces friction. This can extend the machine's lifespan. However, it's important not to over-lubricate. Excess oil can attract dirt and debris, causing more harm than good. Sometimes, maintenance schedules are neglected. This can lead to significant downtime.

Lastly, consider cleanliness. A clean machine operates better. Dust and debris can interfere with the slitting process. Regular cleaning should be part of a maintenance routine. But, it’s easy to overlook this step. Set reminders to ensure consistency. Small lapses in maintenance can lead to larger problems down the line.

Related Posts

-

What is a Sheet Metal Slitting Machine and How Does It Work?

-

Coil Cut to Length Machine Tips for Optimal Performance?

-

Ultimate Tips for Efficient Use of Sheet Coil Cutting Machines

-

Why You Should Choose a Machine Slitter for Your Cutting Needs

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

2025 How to Optimize Your Production with KUKA Machines Efficiently