How to Choose the Right Metal Cut to Length Machine for Your Business?

Choosing the right metal cut to length machine is crucial for your business operations. Industry expert John Smith once said, "The right machine can enhance productivity significantly." This insight reflects the importance of making informed decisions in this vital area.

Understanding your specific needs is the first step. Are you cutting large volumes or smaller batches? The machine's capacity must align with your production goals. A mismatch here can lead to inefficiencies. Pay close attention to features like speed and precision. These details can make or break your workflow.

Investing in a metal cut to length machine requires careful consideration. You must evaluate your budget as well. Some machines are costly, but cheaper options may compromise quality. Balance is key. Keep in mind that the wrong choice could have long-term implications. Reflection on your business needs can guide you in selecting the best machine.

Factors to Consider When Selecting a Metal Cut to Length Machine

When selecting a metal cut to length machine, several factors come into play. The machine's capacity is crucial. According to industry reports, businesses typically require machines that can handle materials ranging from 0.2 mm to 12 mm thick. If the specifications are not suitable, production efficiency drops. This translates to higher operational costs, often up to 20-30% more than expected.

Another vital aspect is the speed of cutting. Advanced machines can process up to 200 meters of material per minute. However, faster does not always mean better. Quality control may suffer as speeds increase. For instance, if tolerances are not maintained within ±0.5 mm, it could lead to a waste of raw materials. A balance must be struck between speed and precision to maximize profitability.

Additionally, the type of metal being cut matters. Some machines excel in cutting steel while struggling with aluminum. This mismatch can be costly and frustrating. A company might invest heavily in a machine only to realize it cannot perform optimally with their existing inventory. Choosing the right machine requires careful consideration. Mistakes made during selection can lead to significant downtime and lost revenue. Always reflect on these aspects to make an informed decision.

Factors to Consider When Selecting a Metal Cut to Length Machine

| Dimension | Details |

|---|---|

| Material Type | Steel, Aluminum, Copper, etc. |

| Thickness Range | 0.2 mm - 10 mm |

| Cutting Lengths | 1 m - 6 m (customizable) |

| Cutting Speed | Up to 120 m/min |

| Accuracy | ±0.5 mm |

| Machine Size | Length: 5 m, Width: 2 m, Height: 1.5 m |

| Power Requirements | 220V, 50/60Hz, 10 kW |

| Control System | PLC with touch screen interface |

| Maintenance | Easy access for regular service |

| Price Range | $30,000 - $100,000 |

Types of Metal Cut to Length Machines Available in the Market

When choosing a metal cut to length machine, understanding the types available is crucial. There are several industrial solutions on the market. Each type serves specific needs. A report by Research and Markets states that the global metal cutting machines market is projected to grow at a CAGR of over 5% by 2026. This trend underscores the importance of selecting the right machine.

One common type is the shear cutting machine. It employs shearing principles to cut metal sheets efficiently. Another option is the laser cut to length machine. It delivers precision and speed but may require significant investment. The plasma cutter is also popular, offering flexibility. However, it may not produce the clean edges that other methods achieve. A survey revealed that 40% of businesses struggle with maintaining blade sharpness, leading to inefficiencies.

In addition, hydraulic cut to length machines are favored for their power. They can handle thicker metals but may be complex. Automation in these machines is increasing. However, it’s important to note that automation can lead to higher maintenance costs. While many machines offer robust features, the right choice ultimately depends on business needs and budget constraints. Balancing precision, cost, and efficiency remains a constant challenge for manufacturers.

Types of Metal Cut to Length Machines

Assessing Your Business’s Specific Production Needs

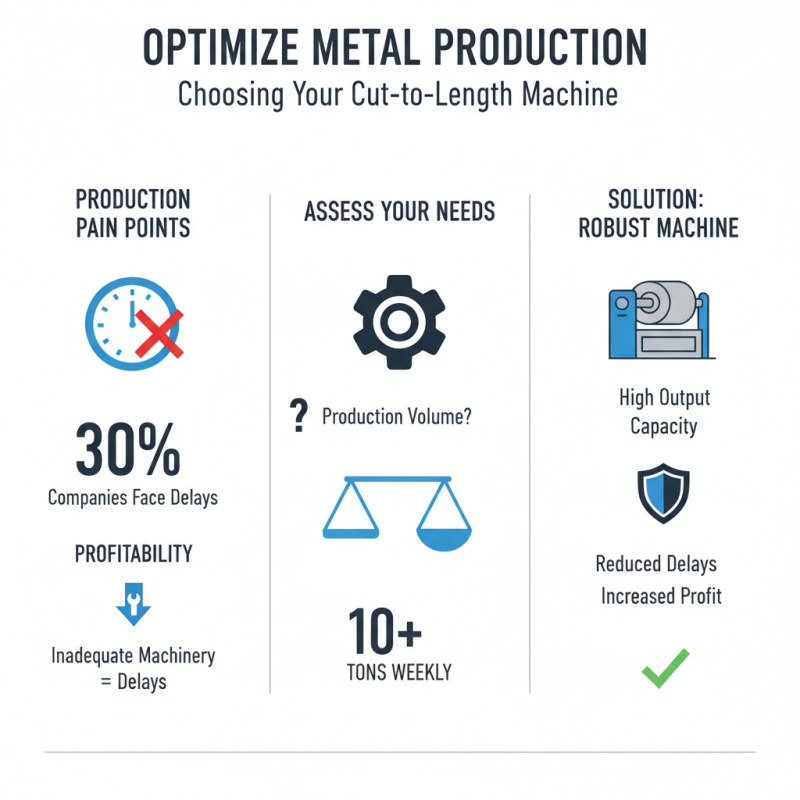

When selecting a metal cut to length machine, it’s crucial to evaluate your production needs. A precise study shows that 30% of companies face production delays due to inadequate machinery. Such delays can severely impact profitability. Understanding your production volume is vital. If your output exceeds 10 tons weekly, you’ll need a robust machine capable of handling higher loads.

Consider the types of metal you will be cutting. Different materials may require unique cutting technologies. For instance, aluminum has a different cutting requirement compared to stainless steel. According to industry reports, machines specifically designed for diverse materials increase efficiency by over 25%. This detail can significantly affect your business operations.

Additionally, reflect on the machine's automation level. A semi-automated machine could be sufficient for lower volumes. However, businesses forecasting growth should consider fully automated options. Research indicates that up to 40% of businesses regretted not investing in automation early on. Balancing the initial investment with long-term gains can be challenging but worthwhile. These factors require careful consideration before making a purchase.

Evaluating Machine Features and Specifications

When choosing a metal cut to length machine, evaluating specific features and specifications is crucial. Look closely at the cutting speed. Machines today can cut at speeds up to 100 meters per minute. High speed can significantly enhance productivity. However, bear in mind that speed should not compromise the cutting quality, as uneven cuts can lead to material waste.

Pay attention to the maximum cutting length as well. Some machines can handle lengths of up to 20 meters, allowing for greater versatility in projects. Yet, larger machines often consume more energy. According to industry reports, energy efficiency is a growing concern, with companies reporting that they lose approximately 15% of their energy costs on inefficient machines. Thus, prioritize a model that balances power and efficiency.

The ease of operation matters too. User-friendly controls can reduce training time and errors. Some machines offer advanced technology, like touch screens and automatic adjustments. However, these features can increase costs. Make sure to assess whether these advanced functionalities truly align with your operational needs and budget constraints.

Budget Considerations and Financing Options for Purchase

When considering a metal cut to length machine, budget is a major factor. Prices can vary widely based on features. A basic machine might be affordable, but will it meet your needs? You might save upfront but spend more on repairs later. Research is key.

Financing options can ease the purchase. Some vendors offer payment plans, which can spread out the cost. Make sure to compare interest rates. A low monthly payment might seem appealing, but watch for hidden fees. Sometimes, the final cost exceeds your initial budget.

Evaluate the total cost of ownership. This includes maintenance, training, and potential upgrades. Investing in a higher-quality machine may require a larger initial outlay, yet could save money long-term. Before committing, reassess your choices. A rushed decision can lead to future regrets.

Related Posts

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

What is a Metal Processing Machine and How Does It Work?

-

How to Choose the Right Coil Cutting Machine for Your Business Needs

-

Top 10 Tips for Choosing the Best Roller Mill Machine for Your Needs

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023