Why You Should Choose a Machine Slitter for Your Cutting Needs

In the ever-evolving landscape of manufacturing and production, the choice of cutting technology plays a crucial role in efficiency and precision. Recent industry reports indicate that the global slitter rewinder market is expected to grow at a CAGR of 5.6% through 2030, driven by the increasing demand for high precision and productivity in various sectors such as packaging, textiles, and metal production. Among the various cutting solutions available, the machine slitter stands out as a superior choice for businesses looking to enhance operational efficiency.

In the ever-evolving landscape of manufacturing and production, the choice of cutting technology plays a crucial role in efficiency and precision. Recent industry reports indicate that the global slitter rewinder market is expected to grow at a CAGR of 5.6% through 2030, driven by the increasing demand for high precision and productivity in various sectors such as packaging, textiles, and metal production. Among the various cutting solutions available, the machine slitter stands out as a superior choice for businesses looking to enhance operational efficiency.

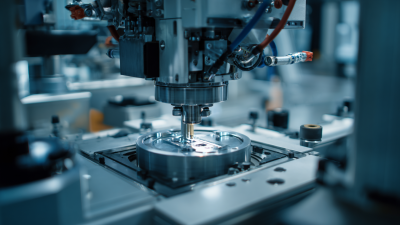

A machine slitter not only provides exceptional accuracy in cutting materials ranging from paper to films and metals, but it also incorporates advanced technology that minimizes waste and optimizes material usage. According to data from the Research Institute of Industrial Production, facilities that have integrated machine slitters have reported a 30% increase in cutting efficiency and a significant reduction in production costs. As companies strive to maintain a competitive edge in a fast-paced market, choosing a cutting solution that offers both precision and reliability is imperative. This introduction of a machine slitter can therefore be a game-changer for industries aiming to elevate their operational capabilities while ensuring high-quality output.

Benefits of Machine Slitters in Precision Cutting Applications

Machine slitters have become an essential tool in precision cutting applications across various industries, offering numerous advantages that enhance efficiency and accuracy. According to a recent report from the Flexographic Technical Association, precision cutting technologies, including machine slitters, can improve production speeds by up to 30% compared to traditional cutting methods. This significant increase in efficiency translates to more output and reduced operational costs, crucial for manufacturers aiming to remain competitive in a rapidly evolving market.

Moreover, machine slitters are designed to provide superior precision, which is critical for industries requiring tight tolerances, such as packaging and automotive. A study from the Industry Association for Advanced Manufacturing indicates that companies utilizing machine slitters report a reduction in material waste by nearly 18%. This reduction not only minimizes material costs but also aligns with sustainability goals, contributing to less environmental impact. Robust automation capabilities further enhance their appeal, as they allow for consistent quality and reduced labor errors, creating a more streamlined production process.

Comparative Analysis: Machine Slitters vs. Manual Cutting Methods

When considering cutting methods for industrial applications, a comparative analysis reveals significant advantages of machine slitters over traditional manual cutting techniques. According to a report by the International Association of Cutting Tools, machine slitters can improve cutting efficiency by up to 30% compared to manual methods. This enhancement is vital in high-output environments, where precision and speed are paramount. Machine slitters employ advanced technology to deliver consistent cuts, greatly reducing the variability often inherent in manual processes.

Furthermore, safety is a critical factor in choosing cutting methods. The Occupational Safety and Health Administration (OSHA) indicates that manual cutting methods can lead to higher accident rates, with around 40% of worker injuries stemming from improper handling of tools. Machine slitters offer built-in safety features that minimize the risk of injuries, thus providing a safer working environment. With operational costs significantly reduced through improved speed and the potential for fewer workplace accidents, it’s clear that machine slitters present a robust solution for modern cutting needs.

Cost Efficiency: Reducing Waste and Maximizing Productivity with Slitters

When considering cutting solutions for your manufacturing needs, a machine slitter can significantly enhance cost efficiency by reducing waste and maximizing productivity. With advancements in technology, such as the rise of laser cutting machines, the integration of cutting-edge machinery has become essential in the quest for high-quality production. This technological innovation not only streamlines the cutting process but also ensures precise cuts that minimize material waste.

**Tips:** When investing in a slitter, always evaluate the potential return on investment. Look for machines that offer versatility, such as adjustable blades for different materials, which can reduce setup time and further decrease waste. Also, consider the maintenance and operational costs of the machinery to ensure it aligns with your budget.

The market is witnessing a notable growth trajectory, particularly in automated laser cutting solutions, which are projected to expand significantly by 2032. This trend highlights the importance of investing in reliable cutting machinery to maintain competitive advantages. Choosing a machine slitter today could very well set the foundation for sustained productivity and operational efficiency in your manufacturing processes.

Cost Efficiency of Machine Slitters

Innovative Technologies in Machine Slitters Enhancing Cutting Quality

Innovations in machine slitting technology have significantly improved cutting quality in various manufacturing sectors. The adoption of high-precision blades and advanced automation has led to remarkable enhancements in production efficiency and product accuracy. According to a report by MarketsandMarkets, the slitting machine market is expected to reach USD 2.1 billion by 2025, growing at a CAGR of 5.8%. This growth is fueled by the increasing demand for precision cutting in industries such as packaging, textiles, and metal processing.

Innovations in machine slitting technology have significantly improved cutting quality in various manufacturing sectors. The adoption of high-precision blades and advanced automation has led to remarkable enhancements in production efficiency and product accuracy. According to a report by MarketsandMarkets, the slitting machine market is expected to reach USD 2.1 billion by 2025, growing at a CAGR of 5.8%. This growth is fueled by the increasing demand for precision cutting in industries such as packaging, textiles, and metal processing.

Moreover, machine slitters now integrate smart technologies such as IoT and AI, which enable real-time monitoring and adjustments during the slitting process. These innovations not only enhance cutting precision but also minimize material waste. A study from the Association for Manufacturing Technology revealed that implementing such advanced machine slitting solutions can reduce production costs by up to 30%. As industries continue to prioritize efficiency and sustainability, the shift towards machine slitters equipped with innovative technologies is poised to transform cutting processes across the board.

Industry Trends: Adoption of Automated Slitting Solutions Across Sectors

The adoption of automated slitting solutions is rapidly transforming various industries, reflecting a broader trend towards increased efficiency and precision. As manufacturers strive to streamline operations, the integration of machine slitters has become crucial. These advanced machines not only enhance productivity but also improve the quality of the cut, ensuring consistency across multiple runs. Industries ranging from packaging to textiles are investing in automation to meet rising demand and to maintain a competitive edge.

Moreover, the shift towards automated slitting is driven by the need for adaptability in an ever-changing market. Manual slitting methods often lead to increased waste and longer lead times, while automated systems can quickly adjust to different materials and specifications. This agility is particularly important in sectors such as aerospace and automotive, where precise cuts are necessary for safety and functionality. As companies increasingly recognize the advantages of machine slitters, we can expect a continued surge in automated slitting solutions, setting the stage for further innovations in manufacturing processes.

Why You Should Choose a Machine Slitter for Your Cutting Needs - Industry Trends: Adoption of Automated Slitting Solutions Across Sectors

| Industry Sector | Adoption Rate (%) | Primary Application | Benefits |

|---|---|---|---|

| Automotive | 65 | Metal Sheet Cutting | Precision, Reduced Waste |

| Packaging | 70 | Flexible Packaging Materials | Speed, Adaptability |

| Textiles | 55 | Fabric Cutting | Consistency, Labor Saving |

| Electronics | 75 | Circuit Board Cutting | Accuracy, Quality Control |

| Construction | 60 | Steel and Plastics | Enhanced Safety, Material Efficiency |