What is a Car Engine Stand and How Do You Use It?

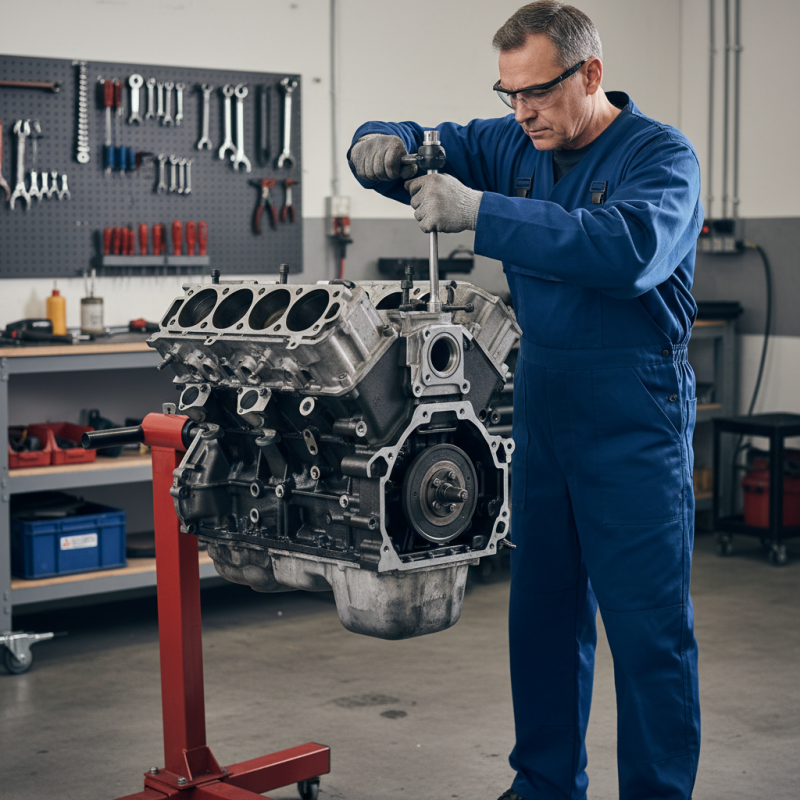

When it comes to car maintenance, a crucial tool is the car engine stand. This stand allows mechanics to safely and easily work on engines outside of the vehicle. John McCarthy, an industry expert, emphasizes, “A good engine stand transforms your workspace and enhances your efficiency.” His words highlight the importance of this equipment in ensuring a smooth workflow in any automotive project.

Using a car engine stand can seem straightforward, yet many overlook its significance. Proper setup and secure mounting are vital to prevent accidents. A wobbly engine can lead to injuries or damaged parts. It's essential to choose the right stand for the weight and size of the engine. After all, safety should always come first.

Don't underestimate the potential challenges. Many users struggle with proper alignment or risk overloading the stand. These common pitfalls can be avoided with careful planning and attention. In the end, a car engine stand is more than just a tool. It represents a commitment to quality and safety in automotive repair.

What is a Car Engine Stand?

A car engine stand is a valuable tool for anyone performing engine work. It provides a stable platform to securely hold an engine during repairs or rebuilds. This tool allows mechanics to work efficiently at eye level, making tasks easier and more precise. With an engine stand, you can rotate the engine freely. This is crucial for accessing different parts without straining.

Using a car engine stand is fairly straightforward, but attention to detail is essential. Begin by securely mounting the engine to the stand, ensuring the bolts are tight. A loose mount can lead to accidents or damage. Check the stand's weight limit and make sure you aren't exceeding it. This mistake can cause the stand to tip over, resulting in injury and costly repairs.

It's also important to adapt to the stand's height. A stand that is too high or too low can awkwardly impact your work posture. Working in an uncomfortable position can lead to fatigue or work-related injuries. Therefore, take time to adjust your workspace to fit your needs. Paying attention to these details can enhance your overall efficiency when working with an engine.

What is a Car Engine Stand and How Do You Use It?

| Feature | Description | Usage Tips |

|---|---|---|

| Purpose | A car engine stand is used to securely hold and rotate an engine for servicing. | Ensure the engine is securely mounted before working on it. |

| Weight Capacity | Typically ranges from 500 to 2000 pounds depending on the model. | Check the manufacturer specifications for weight limits. |

| Materials | Usually made from steel for durability and stability. | Look for corrosion-resistant coatings for prolonged use. |

| Adjustability | Many stands offer height adjustments to accommodate different engines. | Adjust the height according to your working position for comfort. |

| Mobility | Most stands come with wheels for easy movement. | Lock the wheels while working on the engine for safety. |

Benefits of Using a Car Engine Stand

A car engine stand is an essential tool for mechanics and enthusiasts. It provides a stable platform to hold an engine while repairs or modifications are made. Using an engine stand can significantly enhance safety and efficiency during these tasks. In fact, a study by the Automotive Service Association found that organized workspace can improve productivity by up to 30%.

One major benefit of using a car engine stand is the convenience it offers. With an engine securely mounted, both hands are free to work. This allows for easier access to difficult areas of the engine. Removing or installing parts become less cumbersome. Additionally, many stands can rotate the engine, enabling mechanics to inspect all sides without straining. According to a report by the International Journal of Automotive Technology, ergonomics plays a critical role in reducing injury rates in mechanical work. Using a stand can mitigate the risk of strain-related injuries.

Cost-effectiveness is another advantage. While the initial investment in an engine stand may seem significant, it can save money in the long run. Engine stands reduce the likelihood of damage to the engine or surrounding components. A repair that might have cost hundreds could be avoided. However, proper use is essential. A poorly balanced engine on a stand can lead to accidents. Mechanics should ensure that the stand is rated appropriately for the engine's weight.

How to Choose the Right Engine Stand for Your Needs

When selecting the right engine stand, consider the engine's weight and size. Stands come in various capacities. Make sure to match your engine with the stand's specifications. Measure the engine before buying. This step can prevent hassle later.

One tip is to look for adjustable arms. They can provide better support for uneven weight distribution. This feature can stabilize your engine effectively. Remember, an unstable engine can lead to accidents.

Another important point is to think about mobility. Some stands have wheels, making them easier to move. If you plan to use the stand in multiple locations, this can be beneficial. However, wheels can sometimes be a weakness. They may make the stand less stable. Always check that the wheels lock in place.

Engine Stand Usage Frequency by Engine Type

Step-by-Step Guide to Mounting an Engine on a Stand

Mounting an engine on a stand can seem daunting. However, with the right steps, it becomes manageable. Start by ensuring your workspace is clear. Lay out all tools needed. A clean area can make a big difference.

Next, lift the engine onto the stand. This is where a friend can help. Align the engine's mounting points with those on the stand. Use bolts to secure it. Tighten them properly; loose bolts can lead to accidents. Be mindful of your stance and grip during this process.

Tips: Always wear safety gloves. They protect your hands while handling heavy parts. Before starting, confirm that your engine is free of fluids. This prevents spills and ensures safety.

After securing the engine, check stability. A wobbly setup can cause issues later. Make adjustments if necessary. Take your time during this stage to avoid mistakes. Each small step counts toward a successful outcome.

Safety Tips for Using a Car Engine Stand

When working with a car engine stand, safety must always come first. Ensure the engine is securely mounted. Use bolts and clamps that fit properly. A loose engine can lead to dangerous accidents. Remember to check the weight capacity of your stand before use. Overloading can result in catastrophic failure.

Wear protective gear while working. Gloves and safety glasses are essential. They protect you from sharp edges and debris. Clear the workspace of clutter. This helps prevent tripping hazards. Proper lighting is also important. Work in a well-lit area to see all components clearly.

Be aware of your surroundings. If you’re in a garage, make sure tools are organized. A chaotic workspace can lead to mistakes. Take breaks if you feel fatigued. Fatigue can lead to carelessness. Reflect on each step taken; it’s easy to rush. Safety should never be compromised when handling heavy machinery.