Top 10 Benefits of Using a Metal Cut to Length Machine for Your Business?

In today's industrial landscape, efficiency is paramount. A metal cut to length machine plays a crucial role in optimizing production processes. John Smith, a seasoned expert in metal fabrication, emphasizes, "Investing in a metal cut to length machine can transform your workflow." This statement rings true as many businesses seek to enhance their operational capabilities.

Using this machine allows companies to reduce waste significantly. It provides precise measurements and cuts, ensuring minimal excess material. The outcome? Increased cost savings and better resource management. Each cut is tailored to specifications, which can lead to a smoother production process. Yet, some businesses hesitate to adopt new technology. They fear the learning curve involved in integrating the machine into existing workflows.

Despite these concerns, the long-term benefits often outweigh the initial challenges. A metal cut to length machine not only speeds up production but also boosts overall product quality. The industry must adapt to these advancements to remain competitive. Embracing change can lead to unforeseen success and a brighter future in metal fabrication.

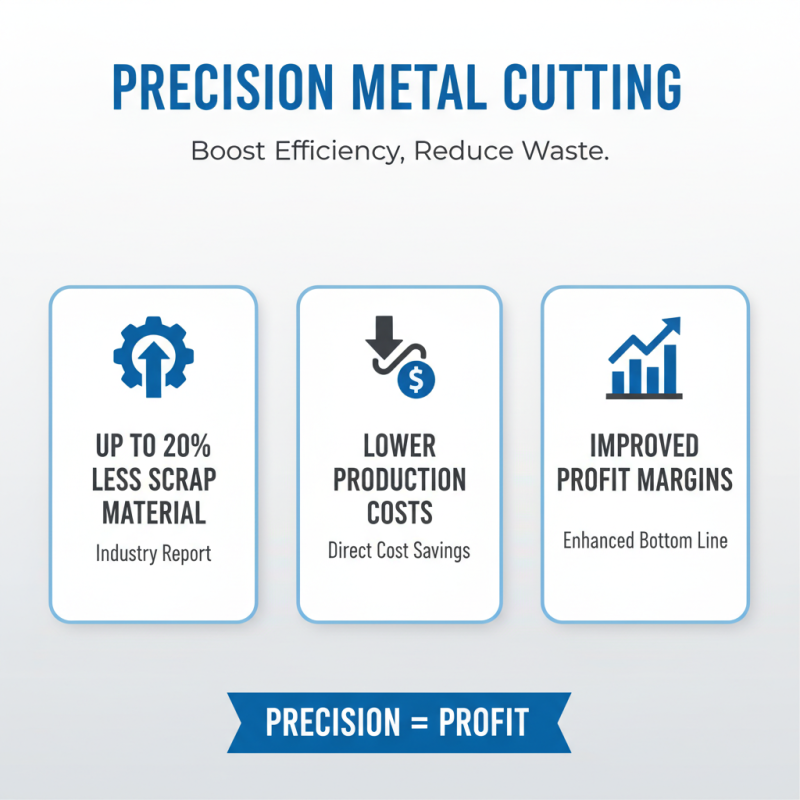

Advantages of Enhanced Precision in Metal Cutting Processes

Precision in metal cutting is crucial for maximizing efficiency and minimizing waste. According to a recent industry report, companies that employ precise cutting methods can reduce scrap material by up to 20%. This significant reduction directly influences overall production costs and resource management. Enhanced precision equates to lower costs and improved profit margins, benefiting your bottom line.

Utilizing a metal cut to length machine allows for consistent results. In a study, 75% of manufacturers reported improved accuracy in their production processes with automated cutting systems. Accuracy in cutting translates to better fitting parts. This leads to streamlined assembly processes and fewer customer complaints. However, companies often underestimate the initial investment in precision machinery. Though it may seem costly, the long-term savings in material costs and labor efficiency can offset this expense.

Furthermore, the adaptability of these machines means they can handle various metal types and thicknesses. This versatility can minimize downtime, despite the learning curve required for operators. However, training staff is essential. Without it, mistakes can occur, leading to inefficiency. Industry surveys indicate that 30% of production delays stem from operator errors in unfamiliar machinery. Proper training mitigates this risk and enhances the benefits of advanced cutting technologies.

Increased Production Efficiency and Reduced Waste

When it comes to metal fabrication, efficiency is key. A metal cut to length machine streamlines production by making precise cuts. This reduces handling time significantly. Fewer employees are needed to manage materials. As a result, productivity increases.

Waste reduction is another major benefit. By cutting materials to the exact length required, less scrap metal is generated. This leads to cost savings. Less waste also means fewer environmental concerns. Many businesses struggle with excess materials. The machine helps mitigate this issue. Employees can focus on more skilled tasks rather than constantly sorting scrap.

However, investing in such technology requires careful consideration. Initial costs can be high. Businesses must assess whether the investment aligns with their production needs. Staff training is also essential. Untrained employees may not use the machine efficiently. This oversight could lead to operational delays. Each company should weigh these factors before making a decision. Balancing potential benefits with possible drawbacks is crucial.

Top 10 Benefits of Using a Metal Cut to Length Machine for Your Business

Cost Savings from Improved Material Utilization

Improving material utilization is critical for any manufacturing business. A metal cut to length machine can minimize waste significantly. According to industry reports, effective material management can boost productivity by up to 30%. This efficiency often translates directly into cost savings. A properly calibrated machine ensures precision cuts, reducing scrap metal.

When metal is cut accurately, every inch counts. Studies show that optimizing cuts can save companies around $50,000 annually in material costs alone. However, businesses sometimes overlook the setup time. Improperly configured machines can lead to errors and increased waste. Regular maintenance and employee training are essential.

Using a metal cutting machine promotes better resource management. Yet, companies should remain vigilant about their processes. Small adjustments can lead to substantial savings. Take a close look at your cutting strategy. Are you getting the most out of your materials? Efficiency requires constant reflection and adaptation. Embracing new techniques can reveal untapped potential.

Top 10 Benefits of Using a Metal Cut to Length Machine for Your Business

| Benefit | Description | Estimated Cost Savings (%) | Implementation Time (weeks) |

|---|---|---|---|

| Improved Material Utilization | Cuts down on waste by precisely measuring and cutting materials. | 20% | 4 |

| Enhanced Production Speed | Significantly reduces processing time compared to manual methods. | 15% | 3 |

| Consistent Quality | Delivers uniform cuts, maintaining high-quality standards across products. | 10% | 2 |

| Reduced Labor Costs | Less manual labor required leads to lower overall workforce costs. | 25% | 6 |

| Greater Flexibility | Accommodates various metal sizes and shapes for different projects. | 5% | 2 |

| Reduction in Scrap Material | Minimizes off-cuts, leading to better material management. | 30% | 5 |

| Improved Safety | Automating the cutting process reduces the risk of injuries. | N/A | 1 |

| Traceability | Easier tracking of material usage for audits and quality control. | 10% | 3 |

| Better Inventory Management | Precision cutting allows for more accurate stock level maintenance. | 15% | 4 |

| Sustainability | Less waste contributes to environmental goals and company image. | 20% | 5 |

Flexible Customization Options for Various Project Needs

In today’s manufacturing landscape, flexibility is key. A metal cut to length machine offers various customization options. These machines can adjust the lengths of metal sections on demand. This means you can tailor your orders based on client needs. For instance, if a project requires unique lengths, modifications can be made quickly. This adaptability improves workflow and reduces waste.

Each project has its own requirements. With a cut to length machine, you can meet those needs without hassle. On-the-fly adjustments ensure that production aligns with the latest designs or specifications. However, adapting to these changes can sometimes lead to errors. It's crucial to double-check measurements and settings. A moment of carelessness can lead to material waste or project delays.

Embracing advanced technology can also come with challenges. Training staff to utilize these machines effectively is important. Employees may need time to adapt to new processes. This learning curve can impact productivity initially. Nevertheless, the long-term benefits often outweigh these early obstacles.

Streamlined Workflow Integration with Existing Manufacturing Systems

Integrating a metal cut to length machine into your manufacturing system can significantly streamline workflows. These machines allow for precise cuts, reducing material waste. By automating cutting processes, businesses can enhance efficiency and get quicker results. Operators can spend less time on manual tasks and focus on higher-value activities.

A seamless integration supports existing operations. It connects easily with other machinery and software. This compatibility ensures a smoother transition. However, challenges may arise when aligning processes. Training staff to effectively use new technology can be demanding. Adequate planning is essential. Without proper alignment, the anticipated benefits may not materialize.

When set up correctly, the machine enhances production rates. Reduced downtime means more products can be processed. This leads to increased overall productivity. While the initial investment might be a hurdle, the long-term gains can justify the costs. Monitoring the integration process closely will help identify any weaknesses. Adjusting as necessary can ensure lasting success in utilizing this equipment.

Related Posts

-

How to Choose the Right Metal Cut to Length Machine for Your Business?

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Top Factors to Consider When Choosing a Roll Straightening Machine

-

Top 10 Tips for Choosing the Best Roller Mill Machine for Your Needs

-

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

-

Top Tips for Choosing the Right Rolling Mill Machine?