Top Benefits of Using a Metal Coil Slitting Machine in Manufacturing Industry?

The manufacturing industry is experiencing rapid growth, with the metal processing market projected to reach $1 trillion by 2026. In this context, the metal coil slitting machine has emerged as a vital tool. This machine enables manufacturers to cut large coils of metal into smaller, more manageable strips. The precision it offers significantly reduces waste, making production processes more efficient.

Utilizing a metal coil slitting machine can enhance product quality. Many companies report improved consistency in strip width and thickness. These machines are designed for high-speed operations, which accelerates production rates. However, not all manufacturers have embraced this technology. Some still rely on outdated methods, potentially hindering their competitiveness.

Moreover, the initial investment in a metal coil slitting machine may seem steep. Yet, the long-term savings from reduced material waste and increased productivity are undeniable. Companies that prioritize modern machinery often find themselves better positioned in the market. The integration of advanced technology can lead to greater operational efficiency, but organizations must continuously reflect on their practices to avoid stagnation.

Benefits of Increased Precision in Metal Coil Cutting Processes

In the manufacturing industry, the precision of

metal coil cutting processes directly impacts product quality.

Metal coil slitting machines enhance accuracy, allowing manufacturers to achieve

tighter tolerances. According to recent industry reports,

companies that invest in advanced slitting technology increase their production efficiency by

up to 30%. This leads to reduced material waste and improved profitability.

Precision in cutting is crucial. Smaller tolerances mean better fits and finishes

in subsequent processes. For example, automotive parts require meticulous cuts

to ensure safety and performance. A deviation of even a few millimeters can lead to significant issues.

Industry data suggests that precise cutting reduces rework rates by nearly

25%. This not only streamlines operations but also fosters customer trust.

Tips: Regular maintenance of slitting machines ensures consistent performance.

Operators should be trained to monitor machine functions closely. This vigilance can prevent minor issues from escalating

into major problems, saving both time and resources. Emphasizing the importance of precision can sometimes overshadow the

need for adaptability in manufacturing. Balancing these two aspects is key to sustained success.

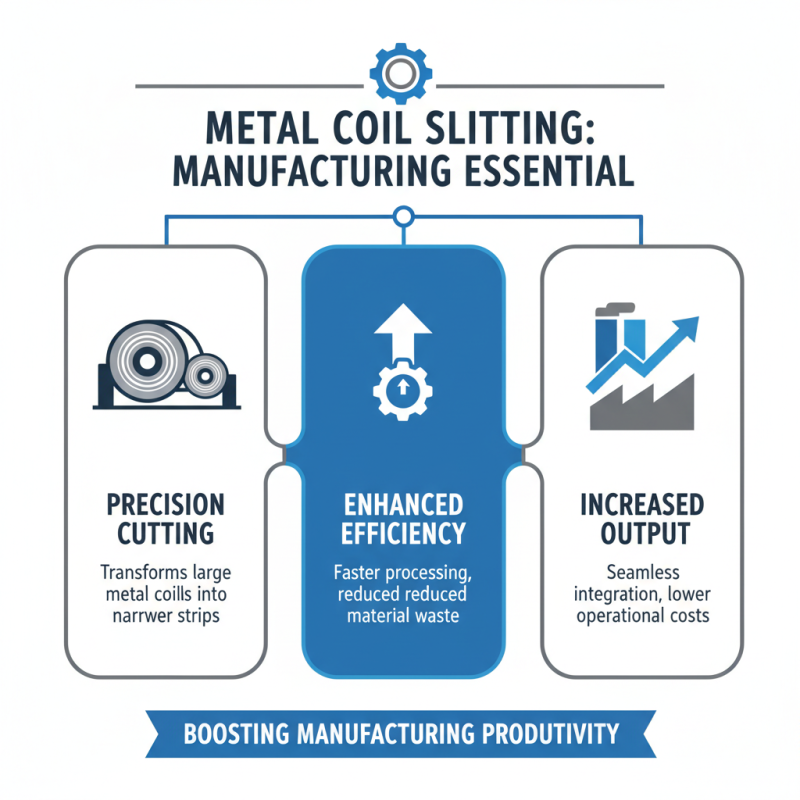

Enhancing Production Efficiency with Metal Coil Slitting Machines

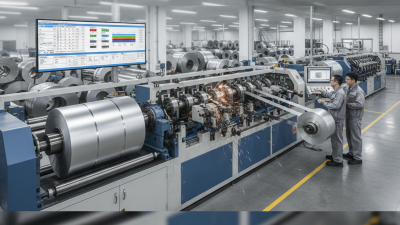

Metal coil slitting machines have become essential in the manufacturing industry. They enhance production efficiency by precisely cutting metal coils into smaller widths. This process allows for better integration into various production lines. Manufacturing plants can increase their output without significantly increasing operational costs.

Using these machines reduces waste. They optimize the use of raw materials by cutting to required specifications. This serves not only the environment but also the bottom line. However, operators need training to ensure accuracy. Misalignment can lead to product discrepancies and wasted materials. Continuous monitoring of the machines is necessary to maintain performance standards.

Moreover, investing in advanced slitting technology can yield long-term benefits. However, initial costs may be higher. Manufacturers must carefully evaluate their return on investment. Balancing efficiency with cost is crucial. It's essential to regularly assess the effectiveness of the slitting process to improve outcomes continuously.

Reducing Material Waste through Advanced Slitting Techniques

The manufacturing industry is constantly seeking ways to improve efficiency. Advanced slitting techniques play a crucial role in reducing material waste. A 2021 report by the International Metalworking Federation noted that up to 30% of materials can be lost during traditional manufacturing processes. By employing modern metal coil slitting machines, manufacturers can significantly cut down this waste.

These machines provide precise cuts, ensuring that materials are used more efficiently. Studies show that improving material usage through slitting can lead to an overall reduction in costs. Manufacturers reported savings of around 15% on raw materials alone. With energy prices rising, such savings can have a major impact. Reduced waste also means less scrap material, which can lower disposal costs.

However, it's not all perfect. Some manufacturers struggle with the initial investment in advanced machinery. The upfront costs can be daunting. Additionally, training staff to use new technology may require time and resources. This investment, though, typically pays off as reduced materials correlate with increased productivity. Balancing efficiency with initial expenses is a challenge worth addressing for sustainable growth.

Versatility of Metal Coil Slitting Machines in Various Industries

Metal coil slitting machines are pivotal in various manufacturing sectors. These machines provide impressive versatility, catering to different materials and thicknesses, which enhances their utility. In automotive, they cut steel coils to precise widths for body panels. This accuracy minimizes waste and improves production efficiency. Users often notice significant time savings during operations, streamlining workflows.

In the construction industry, these machines process aluminum and other metals into needed dimensions. The ability to adapt to several coil widths and weights allows manufacturers to meet diverse project requirements. However, operators may face challenges when adjusting settings for different materials. It requires constant fine-tuning, which can be a learning curve for new users. Regular maintenance also plays a crucial role in ensuring optimal performance.

Furthermore, these machines find application in electronics as well. Precision-cut metal strips are essential for component manufacturing. Amidst these advantages, there are moments when production schedules clash with machinery capability. Balancing speed and quality remains an area for improvement. The multifaceted uses of metal coil slitting machines underscore their significance in boosting operational versatility but require diligent oversight.

Top Benefits of Using a Metal Coil Slitting Machine in Manufacturing Industry

| Benefit | Description | Application Areas |

|---|---|---|

| Increased Precision | Provides precise cutting of metal coils to specified dimensions. | Automotive, Aerospace |

| Cost Efficiency | Reduces waste and optimizes material usage, leading to cost savings. | General Manufacturing, Construction |

| Versatility | Can handle various material types and thicknesses for different applications. | Electronics, Metal Fabrication |

| Speed and Efficiency | Operates at higher speeds, therefore increasing production rates. | Mass Production, Large Scale Operations |

| Quality Control | Ensures consistent quality and surface finish on cut products. | Manufacturing, Aerospace |

Long-Term Cost Savings from Using Metal Coil Slitting Machines

Metal coil slitting machines are increasingly popular in manufacturing. Their efficiency can lead to substantial long-term cost savings. By precisely cutting metal coils, these machines reduce waste and improve material usage. Businesses can optimize production and minimize costs quickly.

Investing in a slitting machine may seem high upfront. However, the savings you gain in the long run can offset this cost. For example, lower scrap rates translate to more usable material. This efficiency can often lower overall production expenses significantly.

Tips for using these machines effectively: Maintain regular inspections to ensure precise cuts. Train staff to operate machinery safely and effectively. Consider the specifications of the metal you’re slitting to choose the right blade parameters. These actions will ensure the machine operates at peak performance.

Top Benefits of Using a Metal Coil Slitting Machine

The following chart illustrates the long-term cost savings and efficiency gains from using metal coil slitting machines in the manufacturing industry. The data reflects average percentages of cost reduction across various key benefits.

Related Posts

-

Top 10 Benefits of Using Stainless Steel Slitting Machines for Your Business

-

Top 10 Coil Shearing Machines for Precision and Efficiency in Metal Processing Industry

-

Top Factors to Consider When Choosing a Roll Straightening Machine

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

Top Tips for Choosing the Right Rolling Mill Machine?

-

2025 How to Optimize Your Production with KUKA Machines Efficiently