Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

As the manufacturing landscape continues to evolve, the aluminum coil slitting machine remains a pivotal component in the production of high-quality aluminum products. This sophisticated machinery is designed to enhance efficiency and precision in slitting operations, making it a key asset for businesses striving to meet the increasing demand in various industries. In 2025, several trends are expected to influence the advancement of aluminum coil slitting machines, shaping their functionality and impact on production processes.

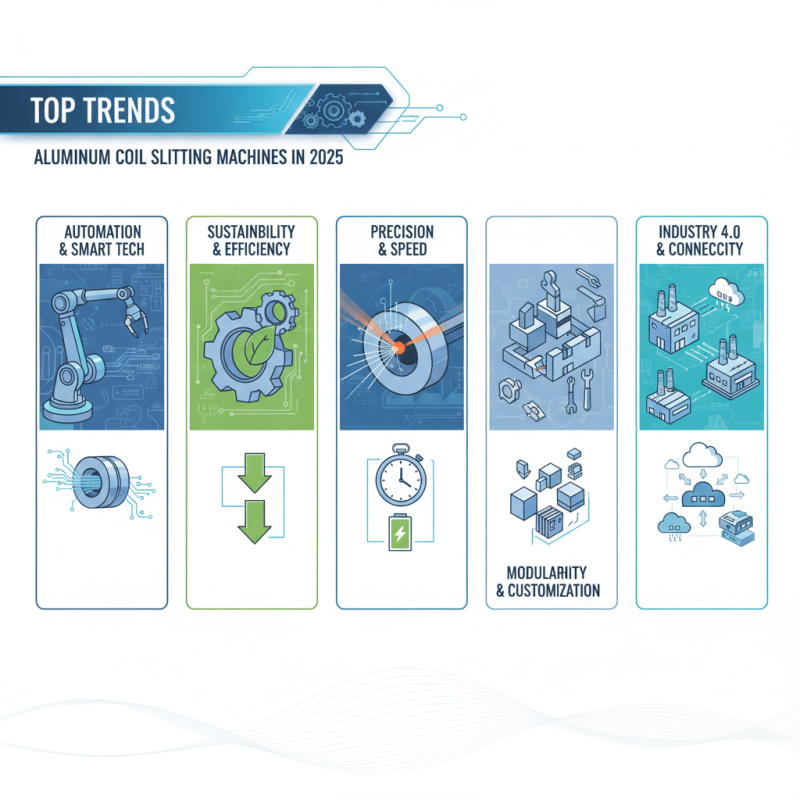

Firstly, the push towards automation and smart technology integration is set to redefine how these machines operate. Enhanced data analytics and connectivity not only streamline operations but also improve maintenance protocols, leading to increased uptime and reduced operational costs. Secondly, sustainability is becoming a central theme, with innovations aimed at reducing waste and improving energy efficiency in slitting processes. As companies aim for greener production practices, aluminum coil slitting machines are likely to evolve to meet these new environmental standards. In this article, we will delve into the top five trends likely to dominate the aluminum coil slitting machine industry in 2025, providing insights into how these developments will shape the future of manufacturing.

Emerging Technologies in Aluminum Coil Slitting Machines for 2025

In 2025, the aluminum coil slitting machine industry is poised to witness significant advancements driven by emerging technologies that enhance efficiency and precision. One of the primary trends is the integration of advanced automation systems. These systems utilize artificial intelligence and machine learning algorithms to optimize slitting processes, reduce waste, and improve overall operational efficiency. By employing real-time data analytics, manufacturers can monitor machine performance and adjust parameters on-the-fly, ensuring consistent quality across production runs.

Another noteworthy trend is the adoption of eco-friendly technologies aimed at reducing the environmental impact of aluminum processing. Manufacturers are increasingly focusing on energy-efficient machines that consume less power and incorporate systems for recycling scrap materials generated during slitting. Innovations, such as advanced blade designs and coatings, are also being explored to enhance durability and reduce the frequency of maintenance. As sustainability becomes a priority, these technologies will not only fulfill regulatory standards but also appeal to eco-conscious consumers, positioning slitting machines as leaders in green manufacturing practices.

Sustainability Practices in the Aluminum Packaging Industry

The aluminum packaging industry is witnessing a significant shift towards

sustainability, driven by

growing environmental awareness and

regulatory pressures. In 2025, we can expect to see innovative practices that not

only minimize waste but also enhance the recyclability of aluminum products.

Companies are increasingly turning to eco-friendly production processes, such

as utilizing renewable energy sources and implementing closed-loop recycling

systems. This trend will not only reduce the carbon footprint of aluminum

packaging but will also bolster its standing as a sustainable option in a

competitive market.

Tips for Embracing Sustainability in Aluminum Packaging:

- Consider investing in advanced recycling technologies that allow for greater material recovery and reuse.

- Explore partnerships with suppliers committed to sustainable practices to ensure your raw materials are sourced responsibly.

- Implement an internal sustainability audit to assess your production processes and identify areas for improvement.

As sustainability becomes a focal point, the aluminum packaging industry can further benefit by engaging consumers on eco-friendly choices. Marketing strategies that highlight the recyclable nature of aluminum and the sustainable efforts of manufacturers can attract environmentally-conscious consumers. By showcasing these initiatives, businesses can reinforce their commitment to sustainability while also meeting rising consumer expectations.

Automation and Smart Technology Integration Trends

The integration of automation and smart technology in aluminum coil slitting machines is set to revolutionize manufacturing processes by 2025. As industries increasingly seek efficiency and precision, advanced automation systems will become a pivotal focus. These innovations will not only streamline operations but also significantly reduce human error. With features such as automated blade adjustments and real-time monitoring systems, manufacturers can expect improved accuracy in slitting, minimizing material waste and enhancing overall productivity.

In addition to automation, smart technology integration is emerging as a crucial trend. The use of IoT-enabled devices will allow for enhanced data collection and analysis, enabling manufacturers to track performance metrics and equipment health in real time. This capability will facilitate predictive maintenance, ensuring machines operate optimally and reducing unplanned downtimes. Furthermore, smart technology can support interoperability between different machines, creating a cohesive production line that responds dynamically to varying demands. This interconnectedness not only optimizes operational efficiency but also paves the way for smarter resource management in the aluminum processing industry.

Top 5 Aluminum Coil Slitting Machine Trends to Watch in 2025

This chart displays the anticipated adoption rates for key trends in aluminum coil slitting machines by 2025. Automation and smart technology are leading the charge, indicating significant shifts in the industry towards more efficient and future-ready solutions.

Market Demands and Consumer Preferences Shaping Machine Design

As we move towards 2025, the aluminum coil slitting machine industry is experiencing significant transformations driven by market demands and evolving consumer preferences. Manufacturers are increasingly focusing on automation and efficiency, with machines designed for faster production rates and reduced downtime. This shift not only enhances productivity but also meets the growing demand for high-quality, precision-engineered products in various applications, from construction to automotive.

Moreover, sustainability has become a paramount concern for consumers, prompting manufacturers to integrate eco-friendly technologies into their designs. This trend is evident in the adoption of energy-efficient motors and recyclable materials, which appeal to environmentally conscious buyers. As companies prioritize sustainable practices, aluminum coil slitting machines are being reimagined to minimize waste and energy consumption, aligning production processes with global sustainability goals.

Tips: To stay ahead in this evolving landscape, consider investing in technologies that enable real-time monitoring and data analytics. This not only optimizes machine performance but also helps in making informed decisions based on consumer trends and market requirements. Additionally, prioritize flexibility in machine design to accommodate various coil sizes and specifications, allowing for a broader range of applications and customer satisfaction.

Innovations in Safety Features for Slitting Operations

In the realm of slitting operations, safety has become a paramount concern, particularly as innovation drives the aluminum coil slitting machine market. By 2025, we anticipate a significant shift in safety features, with industry reports projecting a 30% increase in the implementation of advanced safety mechanisms. These innovations include enhanced emergency stop systems, automatic blade guards, and real-time monitoring technologies that can detect anomalies and prevent accidents before they happen.

As slitting operations can pose inherent risks, incorporating these safety features not only protects workers but also optimizes operational efficiency. For instance, the new generation of machines is designed with integrated safety controls, which are expected to reduce workplace injuries by over 25% compared to older models. Furthermore, user-friendly interfaces and training simulations are becoming standard, ensuring that operators are well-prepared to handle machines safely and effectively.

Tips for enhancing safety in slitting operations include regular maintenance checks on safety devices to ensure they function correctly and providing comprehensive training programs for all operators. Additionally, consider adopting a culture of safety where all employees are encouraged to report potential hazards without hesitation. This proactive approach can lead to not only a safer work environment but also increased productivity and morale within the workforce.

Related Posts

-

2025 How to Optimize Your Cut to Length Machine for Sheet Metal Efficiency

-

Top 7 Steel Coil Cutting Machines for Optimal Efficiency in 2023

-

How to Choose the Right Coil Cutting Machine for Your Business Needs

-

What is a Roller Leveling Machine and How Does It Work?

-

The Ultimate Guide to Choosing the Right Aluminum Slitter Machine for Your Needs

-

Top 10 Tips for Choosing the Best Cold Rolled Slitter Machine