Why Aluminium Rolling Mill Machinery is Essential for Modern Manufacturing?

In the rapidly evolving world of modern manufacturing, aluminium rolling mill machinery plays a pivotal role. According to Dr. James Thorpe, an expert in metallurgical engineering, “The strength of a manufacturing process lies in its machinery.” His insight highlights the critical nature of these machines in producing high-quality aluminium products.

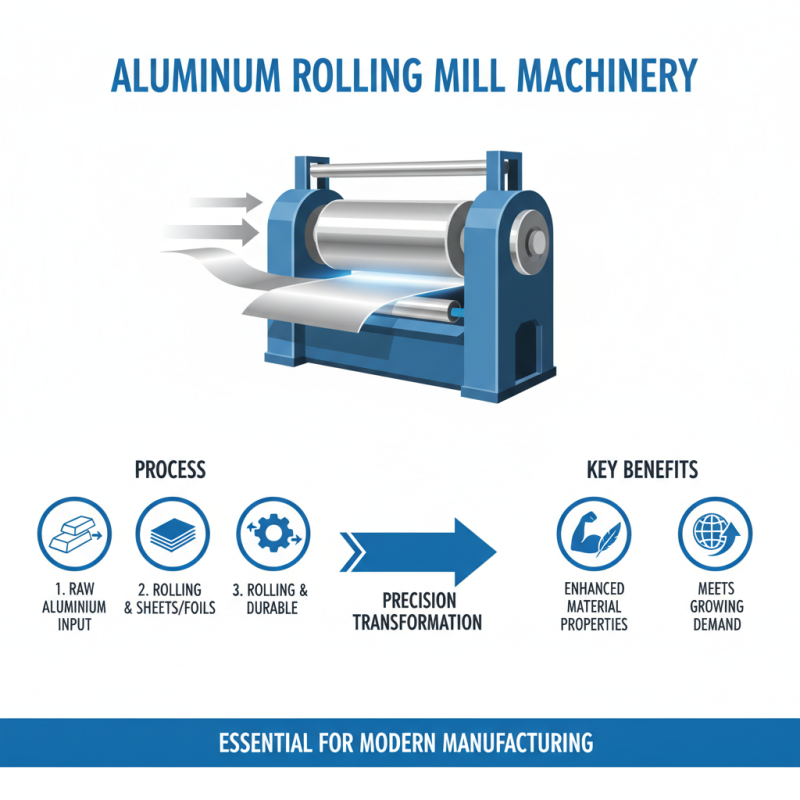

Aluminium rolling mills transform raw metal into thin sheets and foils. This process is vital for various industries, from automotive to aerospace. However, the machinery often faces challenges such as wear and tear, requiring constant attention and innovation.

Companies must invest wisely in their aluminium rolling mill machinery to stay competitive. While many firms have upgraded their equipment, some still use outdated technology. This decision can lead to inefficiency and increased costs. The journey towards modernization is not always smooth. Yet, those who embrace change will find incredible opportunities in the aluminium sector.

The Importance of Aluminium in Modern Manufacturing Processes

Aluminium plays a vital role in modern manufacturing. With its lightweight and strength, it fits various industrial needs. Reports indicate that global aluminium demand is projected to reach 60 million metric tons by 2025. This surge is driven by industries such as automotive, aerospace, and construction. Each sector appreciates aluminium's versatility and durability. For instance, in the automotive industry, aluminium components can reduce vehicle weight by 30%, improving fuel efficiency.

Moreover, the manufacturing process itself relies heavily on advanced machinery. Aluminium rolling mill machinery helps produce sheets and foils essential for numerous applications. Without proper rolling techniques, the quality can suffer. Data shows that poor manufacturing may lead to waste rates as high as 20%. Such inefficiencies can culminate in increased costs and project delays. Thus, investing in high-quality machinery is imperative to meet industry standards and customer expectations.

While many manufacturers are adopting aluminium, challenges remain. Sourcing sustainable raw materials is one concern. Additionally, not all facilities have the necessary tech to leverage aluminium's full potential. It’s a complex landscape. Careful planning and investment are crucial. They can bridge the gap between potential and reality in this booming sector.

Why Aluminium Rolling Mill Machinery is Essential for Modern Manufacturing? - The Importance of Aluminium in Modern Manufacturing Processes

| Aspect | Description | Importance |

|---|---|---|

| Lightweight | Aluminium is significantly lighter than steel, which makes it ideal for transportation and construction applications. | Reducing overall weight can improve fuel efficiency in vehicles and lower shipping costs. |

| Corrosion Resistance | Aluminium naturally forms a protective oxide layer that helps prevent corrosion. | Ensures longevity and durability of products used in harsh environments. |

| Recyclability | Aluminium can be recycled indefinitely without loss of properties. | Promotes sustainability and reduces the need for virgin material extraction. |

| Conductivity | Aluminium is an excellent conductor of electricity, making it essential in electrical applications. | Drives efficiency in power transmission and reduces energy loss. |

| Versatility | Can be easily machined, formed, and finished in various ways. | Applicable in diverse industries from automotive to aerospace and packaging. |

Overview of Aluminium Rolling Mill Machinery and Its Functions

Aluminium rolling mill machinery plays a crucial role in modern manufacturing. This equipment shapes aluminium into various products through processes like rolling and milling. According to a report by Research and Markets, the global aluminium rolling market is projected to reach around $130 billion by 2025, reflecting the machinery's importance.

These machines offer diverse functions, including hot rolling and cold rolling. Hot rolling helps reduce thickness and improves mechanical properties. Cold rolling, on the other hand, enhances surface finish. A study by Statista indicates that the cold rolling process can improve aluminium strength by 20% or more. Yet, many manufacturers struggle with equipment efficiency, leading to high energy consumption and increased production costs.

Technological advancements are needed to address these challenges. Automation and AI integration can optimize the rolling processes. However, transitioning into these advanced systems often requires significant investment, which may deter some companies. Continuous training for operators is also essential to maximize the machinery's potential, as untrained personnel may lead to costly errors.

Aluminium Rolling Mill Machinery Output Analysis

Key Benefits of Using Aluminium Rolling Mill Machinery

Aluminium rolling mill machinery plays a crucial role in modern manufacturing. It transforms raw aluminium into thin sheets or foils with precision. This process enhances the material’s properties, making it more useful in various applications. The demand for lightweight and durable materials is growing. Aluminium rolling mills meet this need effectively.

One key benefit is efficiency. These machines operate at high speeds, reducing production time. They also minimize waste through precise cutting. Additionally, aluminium products produced are uniform in thickness. This consistency is vital in sectors like automotive and aerospace. High-quality rolled aluminium can lead to significant cost savings. However, operating such machinery requires skilled personnel. The complexity of the machines presents a challenge for training.

Another important aspect is sustainability. Aluminium is recyclable, reducing the environmental impact. Efficient mills consume less energy compared to older equipment. However, the initial investment can be substantial. Manufacturers must weigh costs against long-term benefits. Embracing advanced technology in production can seem daunting. Yet, the rewards often outweigh the risks. Investing in aluminium rolling mills is increasingly seen as essential in adapting to market demands.

Impact of Aluminium Rolling Mill Technology on Production Efficiency

Aluminium rolling mill technology has revolutionized modern manufacturing. This machinery plays a vital role in increasing production efficiency. By utilizing advanced processes, manufacturers can significantly reduce waste. The ability to produce thinner sheets of aluminium is one of its many benefits. This change allows for better use of raw materials and lowers costs.

Tips for improving production efficiency include regular maintenance of machinery. A well-maintained rolling mill works more effectively. Operators should also be trained on the latest techniques. This helps in identifying issues promptly. Sometimes, overlooked aspects of operations can lead to delays. Each small improvement contributes to overall productivity.

The technology behind aluminium rolling mills offers more than just speed. It enhances precision in shaping materials. However, investing in this technology requires careful planning. Not all facilities are ready for such a transformation. Embracing newer systems demands resources and commitment. Considering these factors is crucial for successful implementation.

Future Trends and Innovations in Aluminium Rolling Mill Machinery

Aluminium rolling mill machinery has evolved significantly. Innovations are shaping the future of manufacturing. New technologies focus on enhancing efficiency and reducing waste. By integrating advanced automation, mills can operate with minimal human intervention. This adjustment leads to better precision in product specifications.

Moreover, sustainability is a core trend. Eco-friendly practices are now crucial. Manufacturers are investing in energy-efficient equipment. These machines consume less power. They also minimize emissions during production. This shift reflects a growing awareness of environmental impact. However, not all manufacturers have adapted. Some still rely on outdated processes. This gap highlights a need for continual improvement.

Collaboration between engineers and manufacturers drives innovation. New materials and techniques are being explored. Lightweight alloys and enhanced rolling techniques are on the rise. Yet, challenges remain, such as high costs and training requirements. Finding the balance between innovation and practicality is essential for success. Adapting to these trends will determine the leaders in the aluminium industry.

Related Posts

-

2026 Best Hot Rolling Mill Machine Insights and Innovations?

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 Top 5 Steel Mill Machines Revolutionizing the Industry Today

-

Coil Cut to Length Machine Tips for Optimal Performance?

-

Top Factors to Consider When Choosing a Roll Straightening Machine

-

What is a Metal Processing Machine and How Does It Work?