2026 Best Hot Rolling Mill Machine Insights and Innovations?

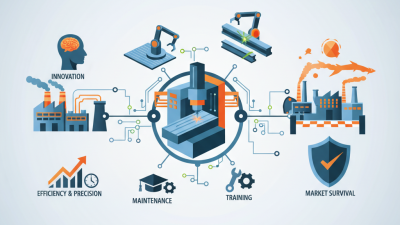

The hot rolling mill machine is a crucial element in metal production. In 2026, the industry is poised for exciting developments. Innovations in technology are changing how these machines operate, improving efficiency and product quality.

Advanced designs are enhancing the heating and rolling processes. With new materials being introduced, the durability of hot rolling mill machines is set to increase. However, the integration of these innovations may not come without challenges. Training skilled operators and maintaining equipment can pose obstacles.

The focus on sustainability is also shifting the paradigm. Energy-efficient systems are becoming vital in new designs. The industry must balance the desire for innovation with the cost implications of new technologies. As we explore the future of hot rolling mills, we must reflect on our progress and the path ahead.

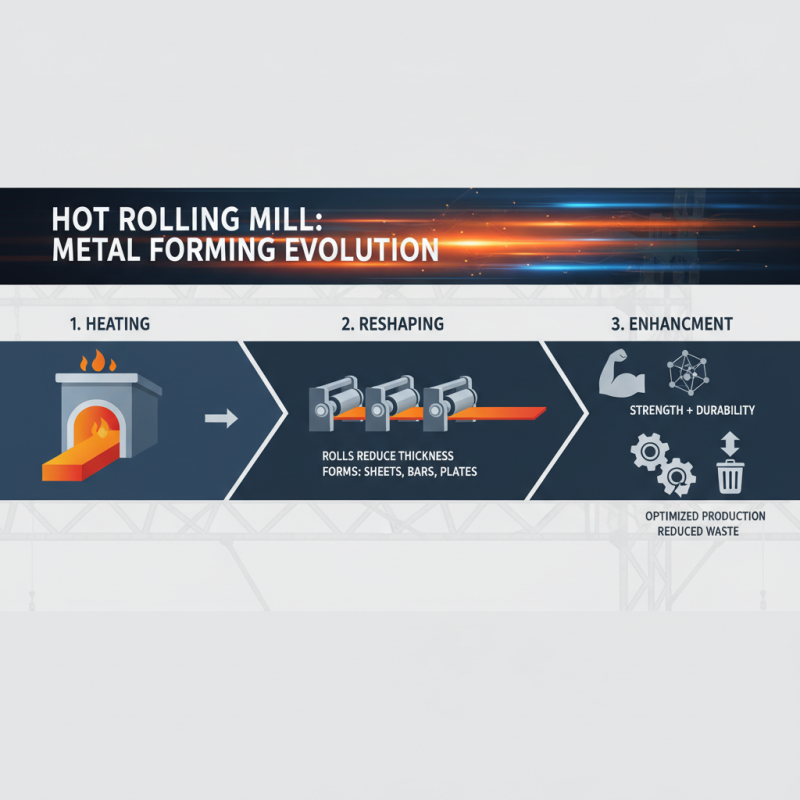

Overview of Hot Rolling Mill Machines and Their Importance

Hot rolling mill machines play a crucial role in the metalworking industry. They reshape heated metal into various forms, such as sheets, bars, and plates. This process enhances the material properties, making them stronger and more durable. With the right machine, manufacturers can optimize production efficiency and reduce waste.

Innovation in hot rolling technology is vital. Advanced features include better temperature control and automated systems. These enhancements improve accuracy and consistency in the final product. However, not all innovations work seamlessly. Some still require significant refining and can lead to operational challenges. Regular maintenance and skilled operators remain essential for success.

The impact of hot rolling mills extends beyond production. They influence supply chains and market dynamics. High-quality rolled products are necessary for construction and automotive industries. Yet, companies often find it challenging to meet rising demands. Balancing quality and quantity is an ongoing concern. Industry players must adapt to these evolving needs and continuously invest in their processes.

Key Innovations in Hot Rolling Technology for 2026

The hot rolling mill industry is evolving. In 2026, we expect to see several key innovations emerging. Advanced automation systems are at the forefront of this change. These systems improve efficiency and reduce labor costs. They also aid in maintaining consistent product quality. Implementing smarter controls can significantly enhance production timelines.

Another significant innovation is the integration of AI and machine learning. These technologies help in predictive maintenance. Operators can foresee issues before they arise, minimizing downtime. Enhanced data analytics provide deep insights into the rolling process. This allows for real-time adjustments to improve yield and performance.

However, the transition isn't without challenges. Machinery updates can be costly and complex. Workers need training to handle new technologies. Additionally, there’s a risk of over-reliance on automated systems. Balancing innovation with human oversight is crucial. By addressing these concerns, the industry can better adapt to advancements in hot rolling technology.

Insights into Hot Rolling Mill Machine Innovations for 2026

Design Enhancements in Hot Rolling Mill Machinery

The design enhancements in hot rolling mill machinery play a pivotal role in improving efficiency and product quality. Advanced technology uses precision components to enhance performance. This includes incorporating real-time monitoring systems for better adjustments during the rolling process. Such features help to minimize defects, yet they require skilled operators for effective use.

New materials are also being explored. Lightweight and durable alloys can improve the lifespan of machine parts. These innovations aim to reduce maintenance needs and operational downtime. However, the transition to new materials often reveals unforeseen challenges. Testing these innovations can be time-consuming and costly.

Another focus is energy efficiency. Upgrades in motor technology and energy recovery systems are pivotal. They promise reduced energy consumption, benefiting both the environment and operational costs. Nevertheless, integrating these systems can lead to initial complications that need addressing. Balancing efficiency with practicality remains a continuous reflection point within the industry.

2026 Best Hot Rolling Mill Machine Insights and Innovations

| Feature | Description | Benefits | Innovations |

|---|---|---|---|

| Automated Control Systems | Advanced systems for real-time monitoring and adjustment. | Improved efficiency and reduced labor costs. | Integration with AI for predictive maintenance. |

| Energy-Efficient Motors | High-efficiency motors that consume less power. | Lower operational costs and reduced carbon footprint. | Use of high-performance rare-earth elements. |

| Improved Roll Design | Innovative geometries to enhance material flow. | Better surface quality and reduced defects. | Application of advanced materials like carbide. |

| Real-time Data Analytics | Analysis of production data to optimize processes. | Enhanced decision-making and process adjustments. | Utilization of big data technologies. |

| Modular Machine Design | Flexible machine layouts that can be reconfigured. | Higher adaptability to production changes. | Implementation of 3D printing for components. |

Sustainability Trends and Environmental Impact in Rolling Mills

In recent years, rolling mills have prioritized sustainability.

Energy efficiency has become a key focus. Many mills are adopting advanced technologies. This reduces emissions and minimizes waste.

Water usage remains a major concern. Significant amounts are often required for cooling.

Recycling systems can be complex, sometimes leading to inefficiencies. Innovations aim to tackle these issues.

Companies are exploring alternative materials. This could lessen the environmental footprint.

Another area of focus is factory layout.

Optimizing space can lead to less energy consumption. Yet, many facilities still operate in outdated structures.

The shift towards greener practices needs to be swift and effective.

Industry leaders must engage in ongoing discussions.

They need to address both current impacts and future goals.

Future Challenges and Opportunities in Hot Rolling Mill Industries

The hot rolling mill industry faces several challenges as it evolves. One pressing issue is the need for energy efficiency. Companies must strive to reduce energy consumption while maintaining production quality. Inefficient processes can lead to higher operational costs. Addressing this is vital for sustainability.

Another challenge is integrating new technologies. Advances in automation and artificial intelligence can enhance productivity. However, adapting these technologies requires investment and training. Many smaller mills may struggle with these changes. Investments in workforce skills are essential. It’s crucial to foster a culture of continuous improvement.

Tips: Regular training sessions can help bridge the skills gap. Encourage employees to share insights on operational efficiency. Implement pilot projects to test new technologies before broader rollouts. These steps can lead to innovation and improved competitiveness. Engage with challenges, and seek proactive solutions for long-term success.

Related Posts

-

How to Choose the Right Coil Cutting Machine for Your Business Needs

-

Top Slitter Machine Steel Features Benefits and Buying Guide

-

2025 Top 10 Cut to Length Machines for Efficient Manufacturing Solutions

-

2025 Top 10 Roller Mill Machines for Efficient Milling and Production

-

Why Metal Processing Machines are Essential for Modern Manufacturing?

-

Coil Cut to Length Machine Tips for Optimal Performance?